Ti3O5 dense block material and preparation methods thereof

A bulk material and dense technology, applied in the field of Ti3O5 dense bulk material and its preparation, can solve the problems of difficult to obtain dense bulk material, prone to phase transition or overreduction reaction, unfavorable development, etc. The effect of high density and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this example, Ti 3 o 5 The preparation method of the dense bulk material is as follows:

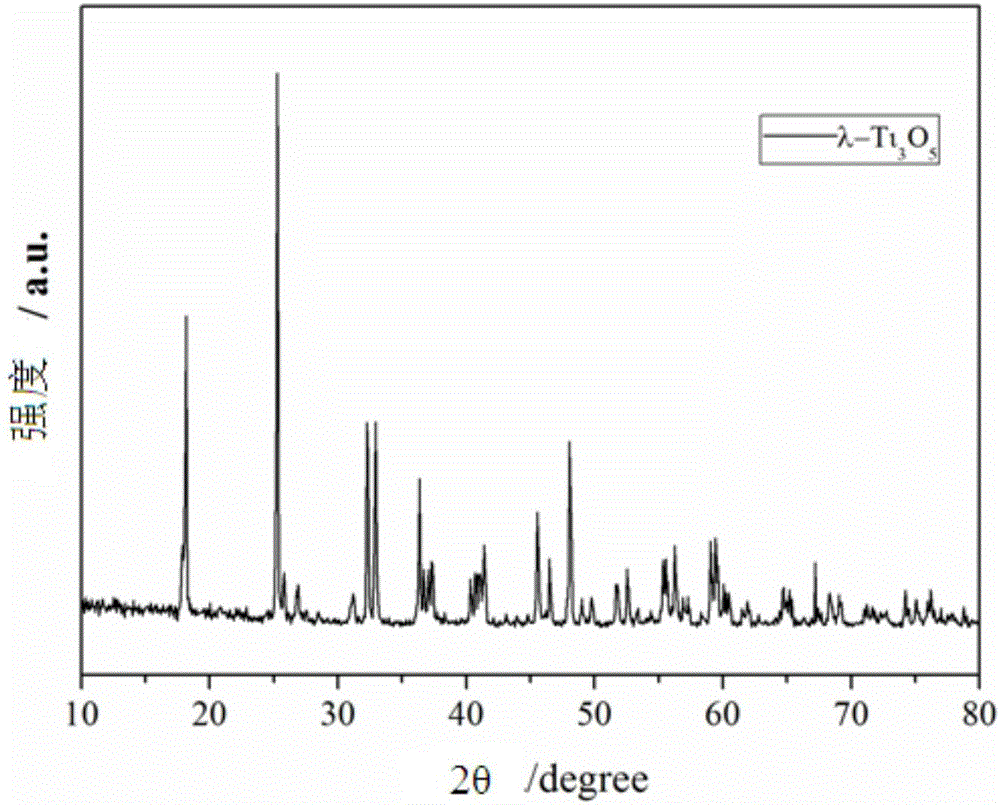

[0047] Ti 3 o 5 The powder raw material is composed of 85wt% λ-Ti 3 o 5 , 14.1wt% Ti 4 o 7 and 0.9wt% residual C composition, the scanning electron microscope of the powder is as follows Figure 4 shown.

[0048] Weigh 15g Ti 3 o 5 The powder raw material is put into a mold with an inner diameter of 10mm. In order to prevent the raw material from reacting or bonding with the inner wall of the mold and the upper and lower pressure heads during the sintering process, and also to facilitate demoulding, the gap between the powder raw material and the mold and between the upper and lower pressure heads Separated with 0.2mm flexible carbon paper. Put the mold filled with powder into the discharge plasma sintering furnace, and apply a continuous sintering pressure of 25KN when the sintering furnace is evacuated until the vacuum degree is lower than 30Pa. 3 o 5 The powder i...

Embodiment 2

[0051] In this example, Ti 3 o 5 The preparation method of the dense bulk material is as follows:

[0052] The raw material used is identical with embodiment 1.

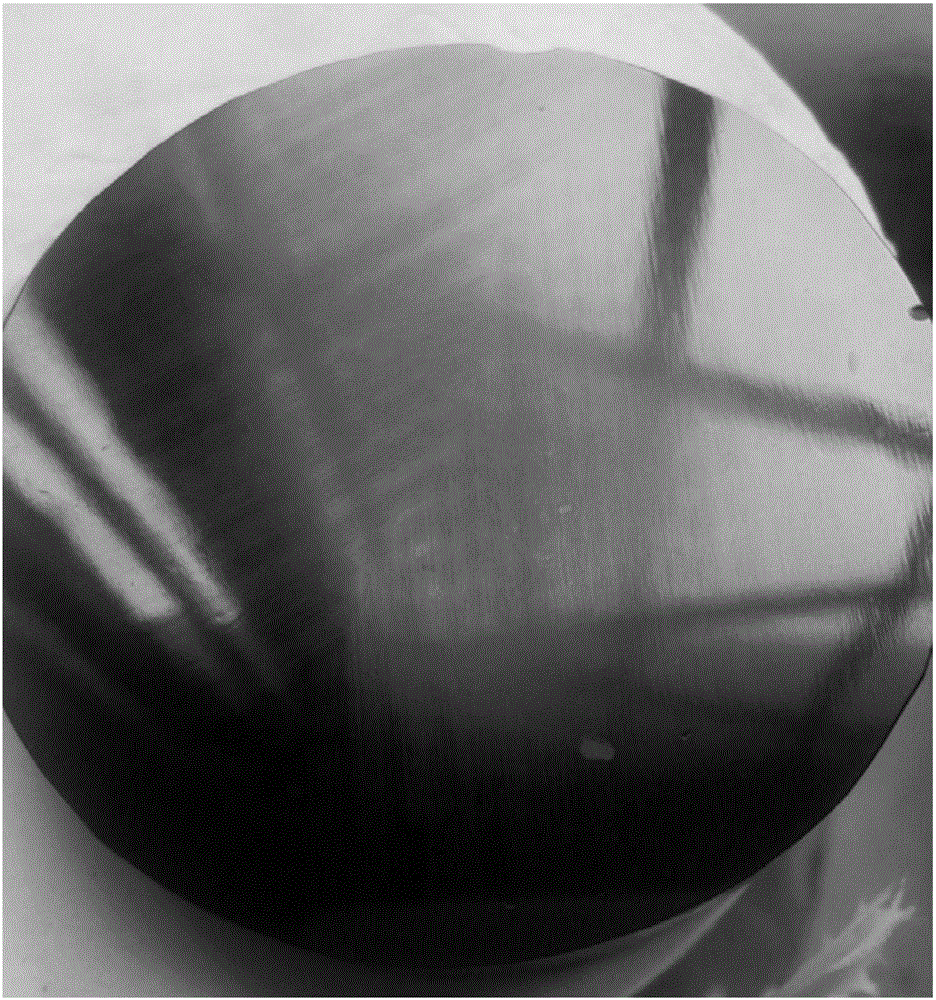

[0053] Weigh 150g Ti 3 o 5 The powder raw material is put into a mold with an inner diameter of 60mm. In order to prevent the raw material from reacting or bonding with the inner wall of the mold and the upper and lower pressure heads during the sintering process, and also to facilitate demoulding, the gap between the powder raw material and the mold and between the upper and lower pressure heads Separated with 0.2mm flexible carbon paper. Put the mold filled with powder into the spark plasma sintering furnace, and when the sintering furnace is evacuated until the vacuum degree is lower than 30Pa, it is filled with nitrogen to normal pressure as a protective atmosphere. Apply a continuous sintering pressure of 100KN, while increasing the sintering current to Ti in the mold 3 o 5 The powder is heated up to a si...

Embodiment 3

[0056] In this example, Ti 3 o 5 The preparation method of the dense bulk material is as follows:

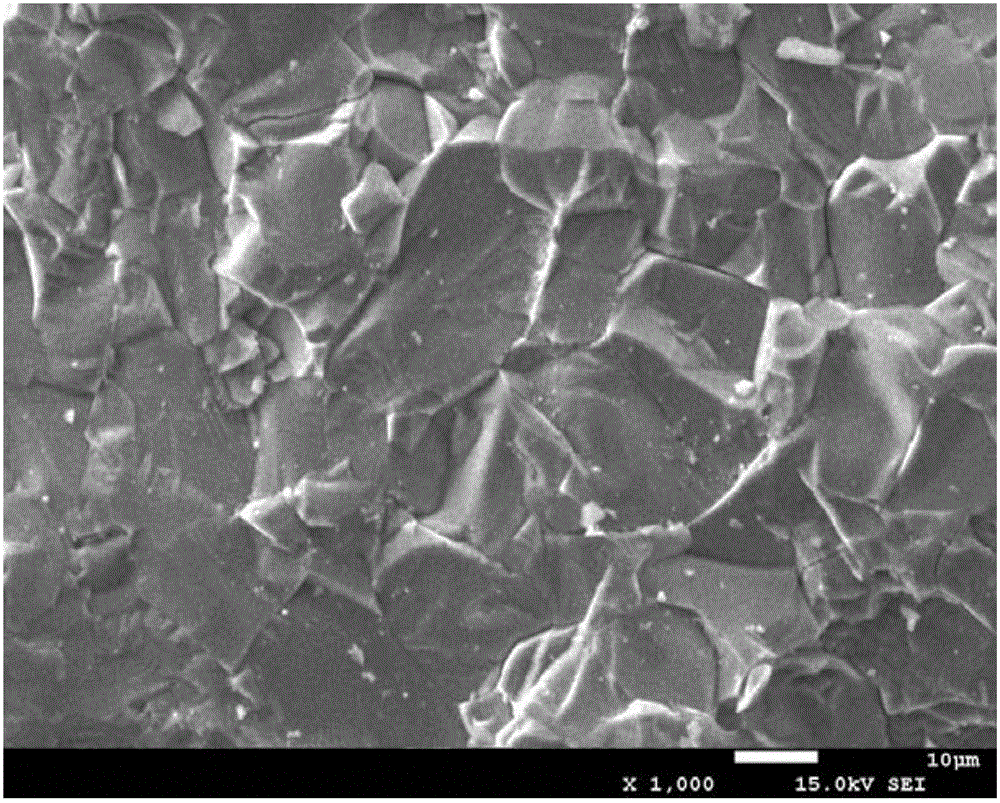

[0057] Ti 3 o 5 The powder raw material is made of 95wt% β-Ti 3 o 5 , 4.9wt%Ti 4 o 7 and a residual C composition of 0.1 wt%. The scanning electron microscope image of the powder is shown in Figure 5 shown.

[0058] Weigh 30g Ti 3 o 5 The powder raw material is put into a mold with an inner diameter of 30mm. In order to prevent the raw material from reacting or bonding with the inner wall of the mold and the upper and lower pressure heads during the sintering process, and also to facilitate demoulding, the gap between the powder raw material and the mold and between the upper and lower pressure heads Separated with 0.2mm flexible carbon paper. Put the mold filled with powder into the spark plasma sintering furnace, and when the sintering furnace is evacuated until the vacuum degree is lower than 30Pa, it is filled with argon gas to normal pressure as a protective at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com