Porous ceramic block, metal-matrix composite and preparation methods of porous ceramic block and metal-matrix composite

A technology of porous ceramics and ceramic slurry, which is applied in the field of composite materials, can solve the problems of less application of new wear-resistant materials, increased labor intensity, and limited performance, and achieve optimized grinding operations, improved work efficiency, and high specific modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

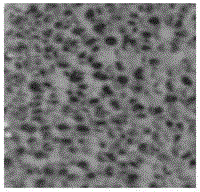

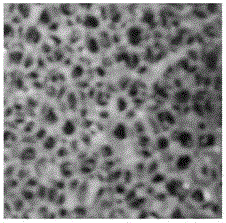

[0055] The porous ceramic block prepared by the preparation method of the porous ceramic block provided by the embodiment of the present invention has no cracks and uniform through holes, and the aperture of the through hole in the porous ceramic block is preferably 4-6mm (the strength of the porous ceramic block with this aperture is higher), suitable for As the composite material of metal matrix composite reinforcement, the metal matrix composite can not only retain the main characteristics of the metal matrix, but also obtain properties that the original metal matrix materials do not have through the composite effect. The metal-matrix ceramic composite material made of porous ceramic blocks as reinforcing materials and metal as the matrix material has excellent properties such as high specific strength, high specific modulus, wear resistance, and high temperature resistance. Applying it to crushing equipment can effectively improve Improve the working efficiency of the crush...

Embodiment 1

[0088] Preparation of porous ceramic blocks

[0089] Polyurethane foam with a PPI of 20 is selected as the organic foam,

[0090] Step 1, pretreatment of organic foam

[0091] Step 1.1, soak the organic foam in water, the temperature of the water is 80°C, and the soaking time is two hours,

[0092] Step 1.2, washing the organic foam obtained in step 1.1 with commercially available Blue Moon hand sanitizer,

[0093] Step 1.3, soaking the organic foam obtained in step 1.2 in an acid solution, the concentration of the acid solution is 10wt%, and the soaking time is 6 hours,

[0094] Step 1.4, soaking the organic foam obtained in step 1.3 in an alkali solution, the concentration of the alkali solution is 10wt%, and the soaking time is 6 hours;

[0095] Step 2, preparation of ceramic slurry

[0096] Mix the ceramic powder, binder and solvent evenly, the average particle size of the ceramic powder is 10 μm,

[0097] The weight ratio of ceramic powder, binder and solvent is: the...

Embodiment 2

[0106] Preparation of porous ceramic blocks

[0107] Polyurethane foam with a PPI of 23 is selected as the organic foam,

[0108] Step 1, pretreatment of organic foam

[0109] Step 1.1, soak the organic foam in water, the temperature of the water is 90°C, and the soaking time is two hours,

[0110] Step 1.2, washing the organic foam obtained in step 1.1 with commercially available Blue Moon hand sanitizer,

[0111] Step 1.3, soaking the organic foam obtained in step 1.2 in an acid solution, the concentration of the acid solution is 10%, and the soaking time is 8 hours,

[0112] Step 1.4, soaking the organic foam obtained in step 1.3 in an alkali solution, the concentration of the alkali solution is 10%, and the soaking time is 8 hours;

[0113] Step 2, preparation of ceramic slurry

[0114] Mix the ceramic powder, binder and solvent evenly, the average particle size of the ceramic powder is 20 μm,

[0115] The weight ratio of ceramic powder, binder and solvent is: the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com