A method for extracting eucommia gum from eucommia leaf bark

A technology of Eucommia ulmoides leaves and eucommia gum, applied in the field of natural product extraction, can solve the problems of unfavorable eucommia gum refining, long fermentation time, low gum purity, etc., and achieves the effects of increasing solubility and mobility, less chemical reagents, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

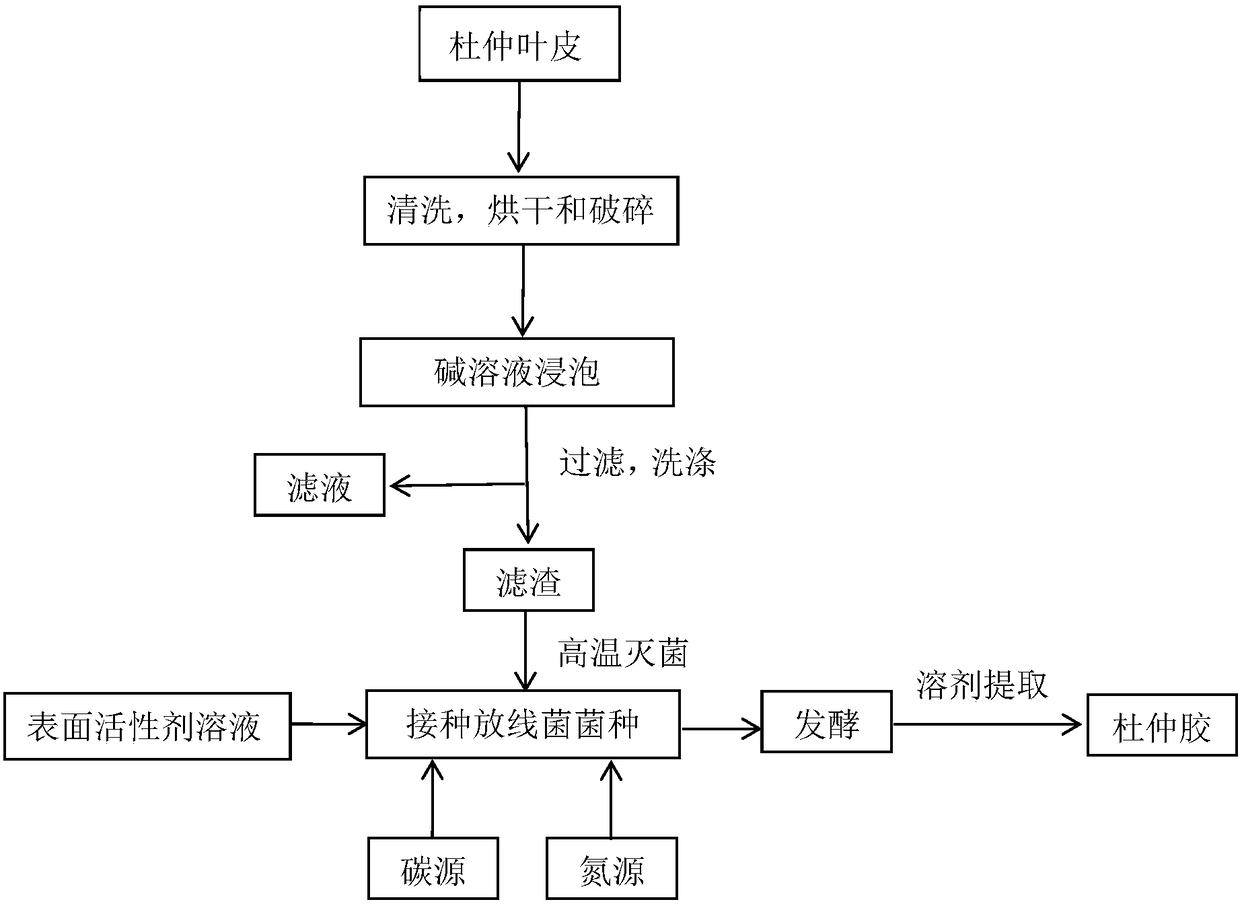

[0026] The method for extracting Eucommia gum in a kind of Eucommia leaf bark that embodiment 1 provides, comprises the steps:

[0027] Clean the eucommia leaf bark, dry and mechanically crush it, soak it in 0.1% NaOH at room temperature for 24 hours, wash and filter it with clean water, filter the obtained filter residue, the pH value of the rinsed filtrate is 8, sterilize the filter residue by high-temperature steam at 200°C, and add 0.05% Aqueous solution of polyethylene glycol octylphenyl ether adjusts the moisture content of the filter residue to 60%, and then inoculates Streptomyces strains, the strain quality is 3% of the dried mass of Eucommia bark leaves, and 0.5% corn flour and 1% urea are added , the initial pH was controlled at 8, the temperature was controlled at 40°C, and fermentation was carried out for 8 days; petroleum ether was added to the fermented Eucommia leaf bark to extract, the ratio of the volume of petroleum ether to the dried mass of Eucommia bark an...

Embodiment 2

[0029] The method for extracting eucommia gum in a kind of eucommia leaf bark that embodiment 2 provides, comprises the steps:

[0030] Clean the eucommia leaf bark, dry and mechanically crush it, soak it in 1% NaOH at room temperature for 12 hours, wash and filter it with clean water, filter the obtained filter residue, the pH value of the rinsed filtrate is 9, sterilize the filter residue with high-temperature steam at 100°C, and add 0.15% The sorbitan monostearate aqueous solution adjusts the water content of the filter residue to 65%, and then inoculates the Streptomyces strain, the strain quality is 5% of the dried quality of Eucommia bark leaves, and adds 0.5% corn flour and 1% urea, The initial pH was controlled at 9, the temperature was controlled at 35°C, and fermentation was carried out for 8 days; the fermented eucommia leaf bark was added to petroleum ether for extraction, the ratio of the volume of petroleum ether to the dried mass of eucommia bark and leaves was 1...

Embodiment 3

[0032] The method for extracting Eucommia gum in a kind of Eucommia leaf bark that embodiment 3 provides, comprises the steps:

[0033] Wash, dry and mechanically crush the leaves of Eucommia ulmoides, soak them in 0.5% NaOH at room temperature for 18 hours, rinse and filter with clean water, filter the obtained filter residue, the pH value of the rinse filtrate is 8.5, sterilize the filter residue with high-temperature steam at 120°C, add 0.1 % polyoxyethylene dehydrated monolaurate aqueous solution to adjust the moisture content of the filter residue to 70%, then inoculate Streptomyces strains, the strain quality is 4% of the dried mass of Eucommia bark leaves, and add 0.5% corn flour and 1% urea , the initial pH was controlled at 8.5, the temperature was controlled at 38°C, and fermentation was carried out for 8 days; petroleum ether was added to the fermented Eucommia leaf bark to extract, the ratio of the volume of petroleum ether to the dried mass of Eucommia bark was 14:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com