Metallic spraying-free polypropylene composite material for automobile exterior trimming part and preparation method thereof

A metal texture and composite material technology, applied in the field of metal texture spray-free polypropylene composite materials and its preparation, can solve problems affecting compatibility, product appearance and metal texture, etc., to achieve easy production and processing, and realize large-scale planning The effect of industrial production and the prospects of large industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

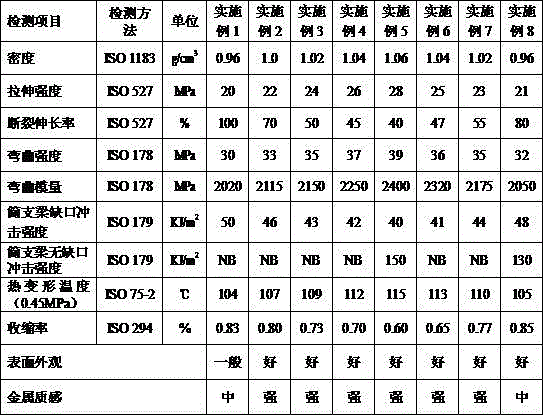

Examples

Embodiment 1

[0039] The metal texture spray-free polypropylene composite material for automotive exterior parts of the present embodiment is composed of the following materials by weight percentage:

[0040] Polypropylene is copolymerized polypropylene, and the melt flow rate of polypropylene is 10g / 10min, 74.6%;

[0041] The elastomer is ethylene-octene copolymer, 5%;

[0042] Inorganic mineral masterbatch is talcum powder masterbatch, 10%;

[0043] The compatibilizer is maleic anhydride grafted polypropylene, 3%;

[0044] Antioxidant is 1010, 0.2%, 168, 0.2%;

[0045] The light stabilizer is 3808, 0.3%;

[0046] The lubricant is polyethylene wax, 0.5%;

[0047] The nucleating agent is a sorbitol nucleating agent, 0.2%;

[0048] Surface modifier, 4%;

[0049] Metallic pigment masterbatch is color silver powder pigment masterbatch, 2%;

[0050] Concrete preparation method comprises the following steps:

[0051] (1) Weigh each raw material according to the formula ratio, and pre-mix...

Embodiment 2

[0054] The metal texture spray-free polypropylene composite material for automotive exterior parts of the present embodiment is composed of the following materials by weight percentage:

[0055] Polypropylene is copolymerized polypropylene, and the melt flow rate of polypropylene is 15g / 10min, 65.1%;

[0056] The elastomer is EPDM rubber, 6%;

[0057] Inorganic mineral masterbatch is wollastonite masterbatch, 15%;

[0058] The compatibilizer is maleic anhydride grafted polypropylene, 4%;

[0059] Antioxidant is 1010, 0.2%, 168, 0.4%;

[0060] The light stabilizer is 3808, 0.4%;

[0061] The lubricant is polyethylene wax, 0.6%;

[0062] The nucleating agent is a sorbitol nucleating agent, 0.3%;

[0063] Surface modifier, 5%;

[0064] The metal pigment masterbatch is colored aluminum powder pigment masterbatch, 3%;

[0065] The specific preparation method is the same as Example 1 of the present invention.

Embodiment 3

[0067] The metal texture spray-free polypropylene composite material for automotive exterior parts of the present embodiment is composed of the following materials by weight percentage:

[0068] Polypropylene is copolymerized polypropylene, and the melt flow rate of polypropylene is 20g / 10min, 54.5%;

[0069] The elastomer is ethylene-octene copolymer, 7%;

[0070] Inorganic mineral masterbatch is talcum powder masterbatch, 21%;

[0071] The compatibilizer is maleic anhydride grafted polypropylene, 5%;

[0072] Antioxidant is 1010, 0.4%, 168, 0.4%;

[0073] The light stabilizer is 3808, 0.5%;

[0074] The lubricant is polyethylene wax, 0.8%;

[0075] The nucleating agent is a sorbitol nucleating agent, 0.4%;

[0076] Surface modifier, 6%;

[0077] Metallic pigment masterbatch is color silver powder pigment masterbatch, 4%;

[0078] The specific preparation method is the same as Example 1 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com