Irradiation-resistant anti-aging sheath material for communication wire harness, and preparation method of irradiation-resistant anti-aging sheath material

A sheath material, radiation-resistant technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems affecting the service life of the sheath, poor radiation resistance, poor aging resistance, etc. Radiation resistance and aging resistance, the effect of improving radiation resistance and improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

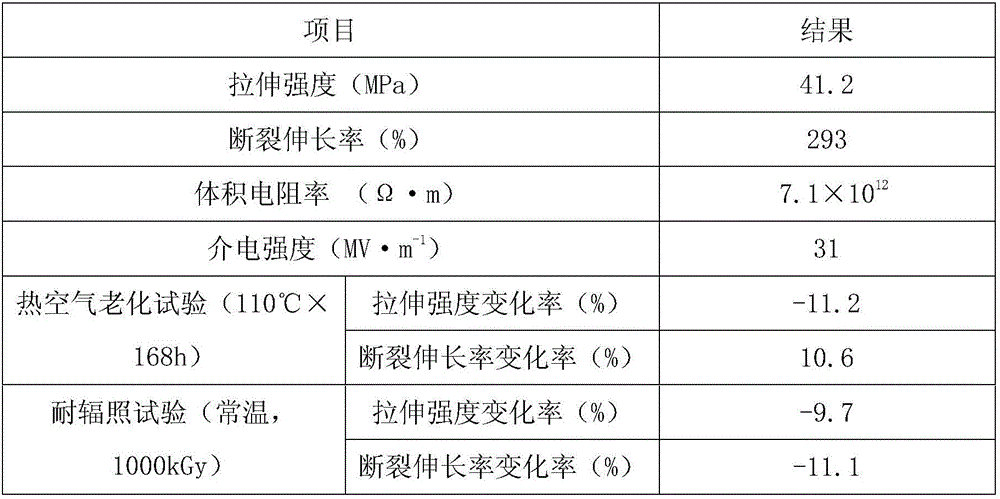

Examples

Embodiment Construction

[0012] An anti-radiation and anti-aging sheath material for communication wiring harness, made of the following materials (kg): PTFE 42, polyetherimide 18, polyphenylsulfone 14, light burnt powder 8, Nano barium sulfate 7, dibutyl phthalate 15, vitamin C palmitate 2.5, ceramic polishing waste 11, low molecular weight polyisobutylene 7, calcium silicate tailings 9, oblique zircon 7, polyoxyethylene oleate 3.5. Behenic acid amide 5, calcium isooctanoate 2.5, zinc isooctanoate 1.5, antimony pentasulfide 4.5.

[0013] A preparation method of radiation-resistant and anti-aging sheath material for communication wiring harness includes the following steps:

[0014] (1) Mix ceramic polishing waste, calcium silicate tailings, and oblique zircon evenly, crush, sieving, and then add a 15% hydrochloric acid solution equivalent to 7 times the weight of the powder, heat the water bath to 70°C, and ultrasonically shake for 30 minutes. Centrifuge at high speed for 20 minutes, let stand for 14 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com