Resin-based powder metallurgy potassium titanate fiber friction material used for vehicle and production method thereof

A technology of iron-based powder metallurgy and powder metallurgy, which is applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of automobile brake disc or drum scratches, friction noise, etc., and achieve good wear resistance and stability Moderate coefficient of friction and modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

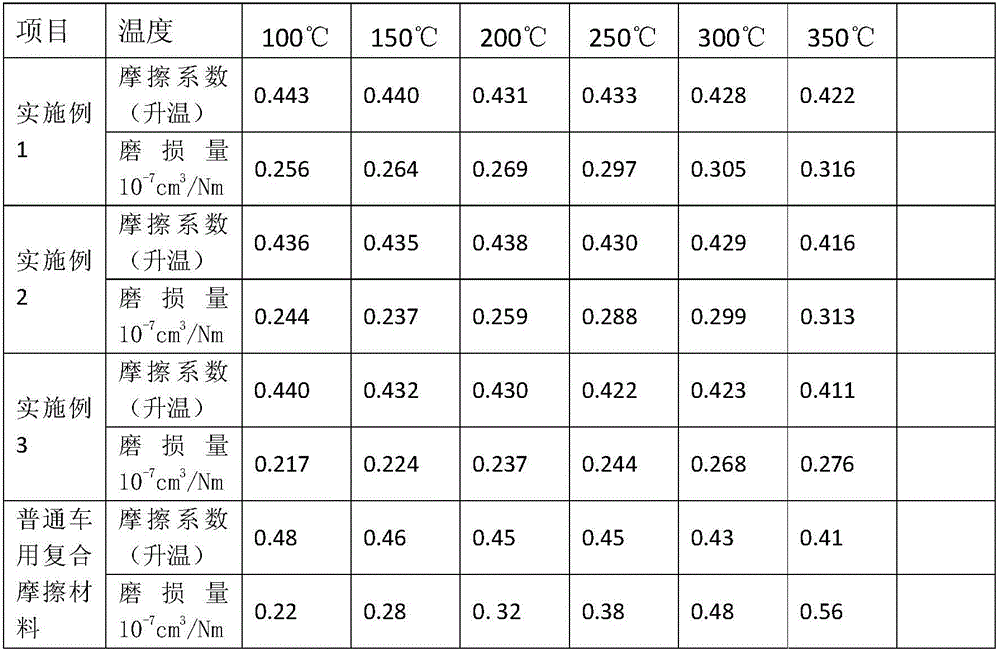

Examples

Embodiment 1

[0030] Preparation of short and fine iron-based powder metallurgy friction material: basic material formula: in terms of mass percentage, the matrix material formula is 50% iron, 5% copper, 3% tin, 10% quartz powder, 15% aluminum oxide, disulfide Molybdenum 2%, graphite powder 15%; forming agent is kerosene, based on the total weight of the mixture, the addition of the forming agent is 0.4% total weight. Mix the above materials evenly, pour them into the mold with a pressure of 500MPa, and press them into a slender rod shape with a diameter of φ2mm×200mm in length, separate each slender rod-shaped green compact, and put it into a sintering furnace. Under the conditions, the temperature rises to 1000°C, keeps the temperature for 4 hours, and cools to room temperature with the furnace.

[0031] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0032] Preparation of composite friction material: basic material...

Embodiment 2

[0038] Preparation of short and fine copper-based powder metallurgy friction material: basic material formula (by mass percentage): 60% iron, 5% copper, 5% quartz powder, 10% aluminum oxide, 3% molybdenum disulfide; calcium fluoride 7%, graphite powder 10%; forming agent is kerosene, based on the total weight of the mixture, the content of the forming agent is 0.5% total weight. Mix the above materials evenly, pour them into the mold with a pressure of 400MPa, and press them into a slender rod shape with a diameter of φ2mm×200mm in length, separate each slender rod-shaped compact, and put it into a sintering furnace. Under the conditions, the temperature rises to 900°C, keeps the temperature for 5 hours, and cools down to room temperature with the furnace.

[0039] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0040] Preparation of composite friction material: material basic formula (by mass percentage...

Embodiment 3

[0046] Preparation of short and fine iron-based powder metallurgy friction material: basic material formula (by mass percentage): 70% iron, 1% tin, 14% quartz stone powder, 5% aluminum oxide, and 10% graphite powder;

[0047] The forming agent is kerosene, based on the total weight of the mixture, and the content of the forming agent is 0.4% by weight. Mix the above materials evenly, pour them into the mold with a pressure of 500MPa, and press them into a slender rod shape with a diameter of φ2mm×300mm in length, separate each slender rod-shaped green compact, and put it into a sintering furnace. Under the conditions, the temperature rises to 1100°C, keeps warm for 2 hours, and cools down to room temperature with the furnace.

[0048] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0049] Preparation of composite friction material: basic material formula (by mass percentage): cashew oil modified phenolic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com