Preparation method of natural gleditsia sinensis handmade soap

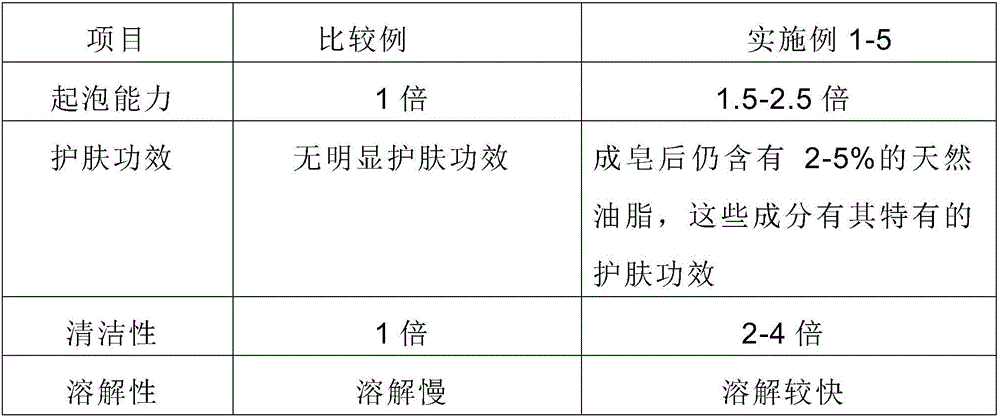

A technology for handmade soap and acacia, which is applied in the directions of chemical instruments and methods, shaped soap, soap detergent composition, etc., can solve the problems of secondary environmental pollution, great harm to human body, etc., and achieves cost saving, good washing effect, and good skin care. health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 10g of acacia powder obtained by grinding acacia, soak in 120g of distilled water, add it to the container after 5h, stir evenly at an electric furnace temperature of 50°C, and boil for 7h;

[0038] Pour the obtained product into a filter device while it is hot, and vacuum filter to obtain the filtrate and residue respectively; wherein, the residue is dried in an oven at 25°C for 5 hours to obtain the residue of acacia extract; add a mass ratio of 4:1 to the filtrate 5% ethanol solution, use NKA-9 macroporous adsorption resin to absorb the pigment of the saponins extract, reduce the brown-red color of the extract, and store it in a low-temperature environment;

[0039] Take coconut oil, olive oil, sweet almond oil, and shea butter with a mass of 10g, 40g, 10g, and 40g, and mix them evenly to obtain a mixed oil with a hardness of 126. Then heat up to 35°C, add 12g of sodium hydroxide and 26g of saponins The solution of the extract is stirred;

[0040] Under stirri...

Embodiment 2

[0043] Weigh 20g of acacia powder obtained by grinding acacia, soak in 180g of distilled water, add it to the container after 5 hours, stir evenly at an electric furnace temperature of 40°C, and boil for 9 hours;

[0044] Pour the obtained product into a filter device while it is hot, and vacuum filter to obtain the filtrate acacia extract and residue respectively; wherein, the residue is dried in an oven at 25°C for 5 hours to obtain the acacia extract residue;

[0045] Adding a mass ratio of 6:1 to 20% ethanol solution in the extract of the acacia extract, using mesoporous activated carbon to absorb the pigment in the extract of the acacia, reducing the brown-red color of the extract, and storing it in a low-temperature environment;

[0046] Mix coconut oil, bitter tea oil, white oil, shea butter and castor oil with a mass of 20g, 30g, 15g, 10g and 15g respectively to obtain a mixed oil with a hardness of 141, then raise the temperature to 37°C, and add 12g of hydrogen The s...

Embodiment 3

[0050] Weigh 15g of the acacia powder obtained by grinding the acacia powder, soak it in 180g of distilled water, add it to the container after 5 hours, stir evenly at an electric furnace temperature of 45°C, and boil for 7 hours;

[0051] Pour the obtained product into a filter device while it is hot, and vacuum-filter to obtain the filtrate and residue respectively; wherein, the residue is dried in an oven at 25°C for 5 hours to obtain the residue of acacia extract; add a mass ratio of 5:1 to the acacia extract The mass fraction is 10% ethanol solution, the acacia extract is used to absorb the pigment with NKA-9 macroporous adsorption resin, and the brown-red color of the extract is reduced, and stored in a low-temperature environment;

[0052] Take palm oil, coconut oil, avocado oil, sweet almond oil and shea butter with a mass of 15g, 15g, 15g, 10g and 15g and mix them evenly to obtain a mixed oil with a hardness of 146. Then heat up to 39°C and add 9g The solution of sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com