Production method of high-titer phages

A production method and phage technology, applied in the fields of biotechnology and microbial products, can solve the problems of complex phage production mode conditions, restricted phage development, and poor production effect, and achieve the effects of convenient application, high production efficiency, and reasonable components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

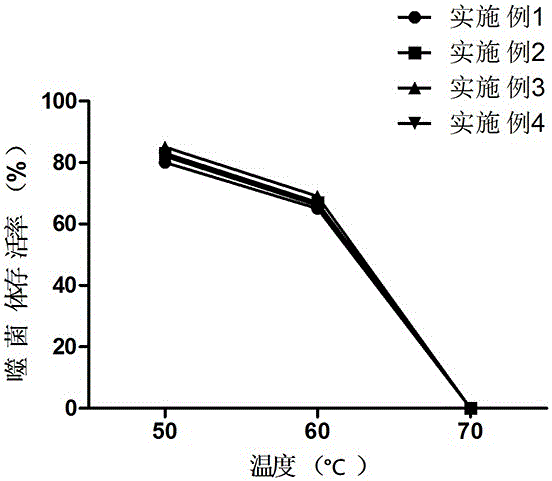

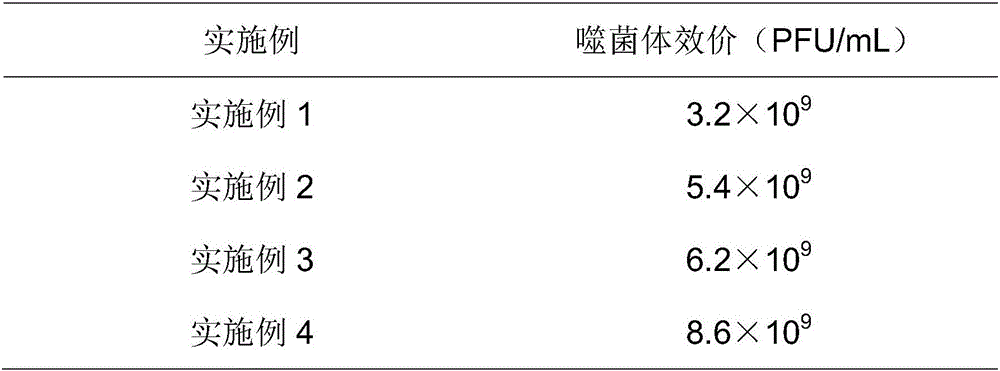

[0029] A method for producing high-titer lactobacillus phage, the steps are completed under 4% humidity conditions, comprising the following steps:

[0030] 1) The frozen Lactobacillus phage mother liquid is added to the Lactobacillus bacterial liquid according to the volume ratio of 1:1, and mixed evenly; the titer of the phage in the phage mother liquid is 10 6 PFU / mL;

[0031] 2) Shake the above mixture at 32°C for 10 minutes at a speed of 80 r / min;

[0032] 3) Spread the mixture in step 2) evenly on the solid medium, and incubate it upside down at 32°C for 8 hours; the solid medium includes the following components by weight: 0.8 parts of tryptone, yeast extract 0.8 parts of powder, 1 part of agarose, 0.3 parts of lactose, 0.3 parts of sodium chloride, 0.1 parts of potassium chloride, 0.5 parts of magnesium sulfate, 0.1 parts of disodium hydrogen phosphate and 100 parts of deionized water;

[0033] 4) Dissolve a single colony on the solid medium in 1 mL of phage buffer, ...

Embodiment 2

[0040] A method for producing high-titer Vibrio alginolyticus bacteriophage, the steps are completed under 6% humidity conditions, comprising the following steps:

[0041] 1) The frozen Vibrio alginolyticus phage mother solution was added to the Vibrio alginolyticus bacterial solution according to the volume ratio of 1:2, and mixed evenly; the titer of phage in the phage mother solution was 10 12 PFU / mL;

[0042] 2) Shake the above mixture at a temperature of 40°C for 20 minutes at a speed of 120 r / min;

[0043] 3) Spread the mixture of step 2) evenly on the solid medium, and incubate it upside down at 40°C for 16 hours; the solid medium includes the following components by weight: 1.2 parts of tryptone, yeast extract 1.5 parts of powder, 2 parts of agarose, 0.6 parts of lactose, 0.8 parts of sodium chloride, 0.5 parts of potassium chloride, 2 parts of magnesium sulfate, 0.3 parts of disodium hydrogen phosphate and 100 parts of purified water;

[0044]4) Dissolve a single co...

Embodiment 3

[0051] A method for producing high-titer mycobacteriophage, the steps are completed under 5% humidity conditions, comprising the following steps:

[0052] 1) The frozen Mycobacterium phage mother solution is added to the Mycobacterium bacterial solution according to the volume ratio of 1:1.5, and mixed evenly; the titer of the phage in the phage mother solution is 10 9 PFU / mL;

[0053] 2) Shake the above mixture at 37°C for 15 minutes at a speed of 100 r / min;

[0054] 3) Spread the mixture in step 2) evenly on the solid medium, and incubate it upside down at 37°C for 10 hours; the solid medium includes the following components by weight: 0.9 parts of tryptone, yeast extract 1 part of powder, 1.5 parts of agarose, 0.5 parts of lactose, 0.6 parts of sodium chloride, 0.3 parts of potassium chloride, 0.9 parts of magnesium sulfate, 0.2 parts of disodium hydrogen phosphate and 100 parts of deionized water;

[0055] 4) Dissolve a single colony on the solid medium in 0.8 mL of phag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Titer | aaaaa | aaaaa |

| Titer | aaaaa | aaaaa |

| Titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com