Bias voltage full-automatic temperature compensation system for APD array chip

An APD array, temperature compensation technology, applied in the control/regulation system, regulating electrical variables, instruments, etc., can solve the problems of small voltage range of high-voltage modules, manual adjustment, inconvenient adjustment, etc., to achieve simple circuit structure and ensure consistency , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

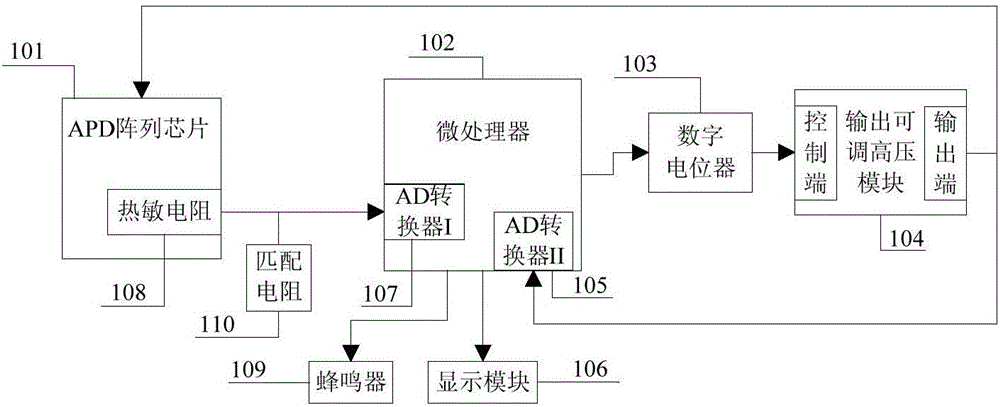

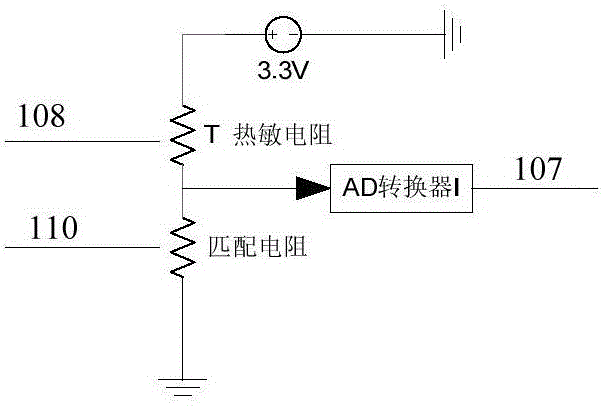

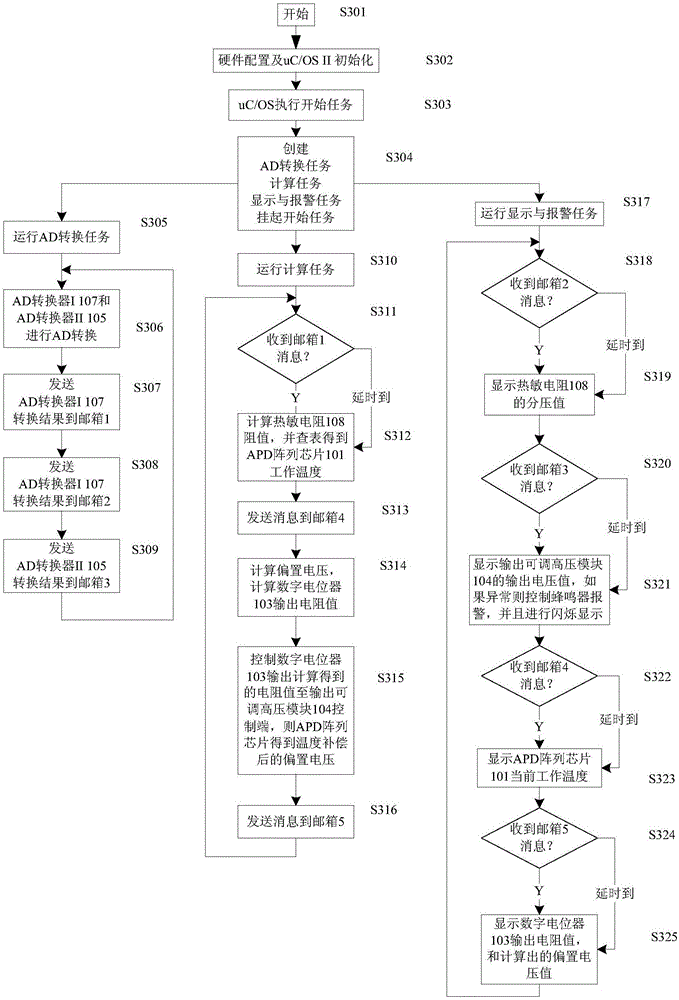

[0024] figure 1 It is a block diagram of a system structure realized according to the present invention. This embodiment consists of an APD array chip 101, a thermistor 108, an AD converter I 107, a matching resistor 110, an AD converter II 105, a microprocessor 102, a digital potentiometer 103, Output adjustable high voltage module 104, buzzer 109 and display module 106 constitute. Thermistor 108 is fixed on the APD array chip 101; AD converter I is connected to thermistor 108 and matching resistor 110; the output end of output adjustable high voltage module 104 is connected to AD converter II 105 and APD array chip 101; output is adjustable The control terminal of the high voltage module 104 is connected with the digital potentiometer 103 ;

[0025] The APD array chip 101 is a 5x5 square APD array chip produced by Germany First sensor company in this embodiment. 25 APD units are integrated on the chip, and these APD units form a 5x5 square array.

[0026] Thermistor 108 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com