Electrode with excellent rate capability and current cycling performance

A technology of rate performance and cycle performance, applied in battery electrodes, electrode carriers/current collectors, nanotechnology for materials and surface science, etc. Excellent rate performance and cycle performance, good structural consistency, and the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

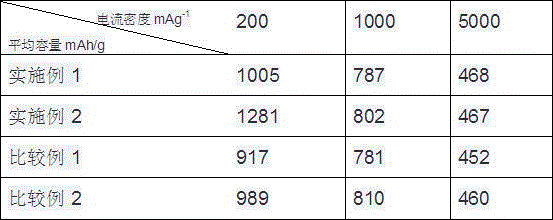

Examples

Embodiment 1

[0021] 1) Weigh 1.1g of high molecular weight polyacrylamide, 0.8g of medium molecular weight polyacrylamide, 0.8g of low molecular weight polyacrylamide, and 2.3mmol of metal salt and 4.7mmol of precipitant and add to 2.9mL deionized water, put it in a constant temperature water bath at 70~88°C for 6 hours with magnetic stirring to dissolve it completely, forming a transparent solution; the metal salt is selected from ferric nitrate; the precipitant is selected from phosphoric acid;

[0022] 2) Add the precursor solution in step 1) to the injection, perform electrospinning under the conditions of positive high voltage 18kV and negative high voltage -1.8kV, receive nanofibers with aluminum foil, adjust the distance between the needle and the receiving plate to 18 cm, spin The advancing speed of silk liquid is 1.4mL / h;

[0023] 3) Place the nanofibers obtained in step 2) in an oven at 120°C to dry for 5 hours;

[0024] 4) The composite nanofibers obtained by electrospinning in...

Embodiment 2

[0028] 1) Weigh 1g of high-molecular-weight polyacrylamide, 1g of medium-molecular-weight polyacrylamide, 0.8g of low-molecular-weight polyacrylamide, and 2mmol of metal salt and 5mmol of precipitant into 30mL of deionized water at the same time , put it in a constant temperature water bath at 70°C and magnetically stir for 6 hours to dissolve it completely to form a transparent solution; the metal salt is selected from magnesium chloride; the precipitant is selected from diammonium hydrogen phosphate;

[0029] 2) Add the precursor solution in step 1) to the injection, perform electrospinning under the conditions of positive high voltage 18kV and negative high voltage -1.4kV, use aluminum foil to receive nanofibers, adjust the distance between the needle and the receiving plate to 15 cm, spin The advancing speed of silk liquid is 1mL / h;

[0030] 3) Place the nanofibers obtained in step 2) in an oven at 120°C to dry for 5 hours;

[0031]4) The composite nanofibers obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com