Potato starch processing juice lactic acid beverage and preparation method thereof

A technology of potato starch and lactic acid beverage, applied in the directions of bacteria, Lactobacillus, Streptococcus/Lactococcus, etc. used in food preparation, can solve the problems of unsuitable industrialized food processing field, difficulty in preparing good flavored beverages, loss of nutrients, and the like, Achieving good market prospects, moderate acidity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

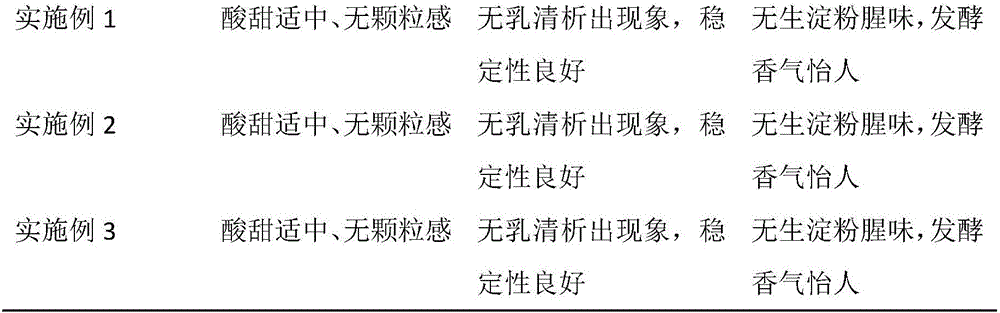

Embodiment 1

[0032] (1) Enzymatic hydrolysis treatment of potato starch waste juice

[0033] Filter the fresh waste juice (not more than 6 hours after processing) produced by potato starch processing through a 100-mesh filter cloth to remove large particle impurities. Add high-temperature-resistant α-amylase according to the addition amount of 150U / mL, carry out liquefaction treatment at 65°C for 20 minutes, cool slightly, then add glucoamylase at 200U / mL (both enzyme preparations are commercially available solid or liquid products), and proceed at 60°C Saccharification treatment for 50 minutes to obtain enzymatic juice.

[0034] (2) Composition, homogenization and sterilization of fermented juice components

[0035] Add sucrose to the enzymolysis juice obtained in the first step to make the sugar content reach 12%, add fresh milk or skimmed milk powder to make the protein content to 1.0%, add 0.5% (relative to the total weight of the enzymolysis juice) compound to stabilize After stirri...

Embodiment 2

[0046] (1) Enzymatic hydrolysis treatment of potato starch waste juice

[0047] Filter the fresh waste juice (not more than 6 hours after processing) produced by potato starch processing through a 100-mesh filter cloth to remove large particle impurities. Add high-temperature-resistant α-amylase according to the addition amount of 200U / mL, perform liquefaction treatment at 80°C for 10 minutes, cool slightly, then add glucoamylase at 350U / mL (both enzyme preparations are commercially available solid or liquid products), and carry out at 62°C Saccharification treatment for 30 minutes to obtain enzymatic juice.

[0048] (2) Composition, homogenization and sterilization of fermented juice components

[0049] Add sucrose to the enzymolysis juice obtained in the first step to make the sugar content reach 18%, add fresh milk or skimmed milk powder to make the protein content reach 4.5%, add 1.5% (relative to the total weight of the enzymolysis juice) compound stabilizer After stirr...

Embodiment 3

[0058] (1) Enzymatic hydrolysis treatment of potato starch waste juice

[0059] Filter the fresh waste juice (not more than 6 hours after processing) produced by potato starch processing through a 100-mesh filter cloth to remove large particle impurities. Add high-temperature-resistant α-amylase according to the addition amount of 180U / mL, carry out liquefaction treatment at 70°C for 15 minutes, cool slightly, then add glucoamylase at 250U / mL (both enzyme preparations are commercially available solid or liquid products), and carry out at 61°C Saccharification treatment for 40 minutes to obtain enzymatic juice.

[0060] (2) Composition, homogenization and sterilization of fermented juice components

[0061] Add sucrose to the enzymolysis juice obtained in the first step to make the sugar content reach 16%, add fresh milk or skim milk powder to make the protein content to 2.5%, add 1% (relative to the total weight of the enzymolysis juice) compound to stabilize After stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com