Anti-cancer drug prepared by using 3D printing technology, and method

An anti-cancer drug, 3D printing technology, applied in the direction of anti-tumor drugs, drug combinations, pharmaceutical formulations, etc., can solve the problems of complex, slow-release properties without any special outstanding performance, single appearance, etc., and achieve good therapeutic effects. and experience, simple operation, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A 3D printed anticancer drug, the preparation process is as follows:

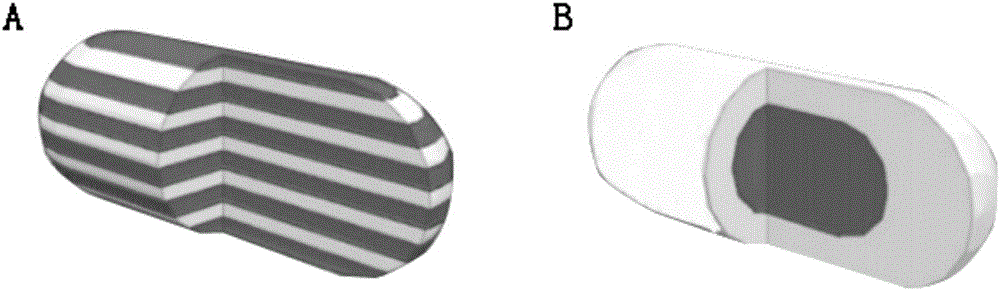

[0047] (1) Using computer-aided design special software (AutoCAD3DMax2015), design a drug particle model with an elliptical multilayer structure ( figure 1 A), the volume is 310mm 3 .Save this model as an STL format file, process it with layering software (ezlayout_reg1.26), and finally process it to get the most suitable file for printing, and import it into a 3D printer (Tianwei 3D printer CoLiDo X3045).

[0048] (2) 2.5g doxorubicin (manufactured by Wuhan Dahua Weiye Pharmaceutical Chemical (Group) Co., Ltd., melting point 205°C) drug crystal powder and 250g dried polyvinyl alcohol granules (Shanghai Emma Biotechnology Co., Ltd., SIGMA model) ) and 0.25g auxiliary material γ-polybenzyl glutamate were mixed uniformly, placed in the mixer and set at 100rpm to run for 15 minutes; the uniformly mixed material was put into the SJ single-screw plastic extruder, and the The temperature setting is: 170°...

Embodiment 2

[0052] (1) Using computer-aided design special software (AutoCAD3DMax2015), design a drug particle model with an elliptical inner and outer double-layer structure ( figure 1 -B model), the volume is 310mm 3 . Save this model as an STL format file, process it with layering software (ezlayout_reg1.26), and finally process it to get the most suitable file for printing, and import it into a 3D printer (CoLiDo X3045, a 3D printer from Tianwei Company).

[0053] (2) 12.55g paclitaxel (produced by Guangzhou Aichun Pharmaceutical Technology Co., Ltd., melting point 213°C) drug crystal powder was mixed with 250g dried polyvinyl alcohol polymer particles and 0.25g adjuvant gamma-polybenzyl glutamate, Set the mixer to run at 100rpm for 10 minutes; put the uniformly mixed material into the SJ single-screw plastic extruder, and set the temperature of the single-screw plastic extruder to: 170°C in the first zone of the machine head and 180 in the first zone of the barrel ℃, 178℃ in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com