Production technology of wet-activated-carbon-based potassium sulfate

A wet-process activated carbon and production technology technology, applied in the directions of alkali metal sulfite/sulfite, potash fertilizer, chemical instruments and methods, etc., can solve the problem of low utilization rate of potash fertilizer, etc. The effect of improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

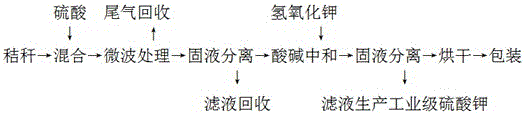

Image

Examples

Embodiment 1

[0040] (1) Crush wheat straw to 80 mesh to obtain 500 g of wheat straw powder, and spray 1000 g of water to moisten it;

[0041] (2) According to step (1) the weight ratio of wheat straw powder and sulfuric acid with a concentration of 93wt% is 1:10, mix the wheat straw powder obtained in step (1) with sulfuric acid, and place it in a microwave oven at 700W, 2450MHz (equivalent to Heat the reaction at about 120°C for 20 minutes, take it out and stir it, then place it in a microwave oven and heat it for 15 minutes to obtain the reactant;

[0042] (3) The reactant obtained in step (2) is subjected to solid-liquid separation to obtain a solid product and a filtrate.

[0043] (4) The solid product obtained in step (3) is neutralized to about pH7 with 30% waste potassium hydroxide.

[0044] (5) Separating the neutralized product in step (4) into a solid product and a filtrate, and the solid product is wet-process activated carbon-based potassium sulfate.

[0045] The filtrate is ...

Embodiment 2

[0049] (1) Crush the bagasse to 100 mesh to obtain 1000g of bagasse powder, and spray 1000g of water for wetting;

[0050] (2) According to step (1), bagasse powder and sulfuric acid with a concentration of 98wt% were mixed in a weight ratio of 1:20, and stirred and reacted at 100°C for 4 hours to obtain a reactant;

[0051] (3) The reactant obtained in step (2) is subjected to solid-liquid separation to obtain a solid product and a filtrate.

[0052] (4) The solid product obtained in step (3) is neutralized to about pH 7.0 with 32% liquid potassium hydroxide.

[0053] (5) Separating the neutralized product in step (4) into a solid product and a filtrate, and the solid product is wet-process activated carbon-based potassium sulfate.

[0054] The filtrate is concentrated to produce industrial grade potassium sulfate.

[0055] The test results are as follows:

[0056] Wet-process activated carbon-based potassium sulfate weight 2823.5g (dry basis 1371.2g), water content 51.44%...

Embodiment 3

[0058] (1) Crush the rice straw to 400 mesh to obtain 100g of rice straw powder, and spray 50g of water to moisten it;

[0059] (2) According to step (1), rice straw powder and sulfuric acid with a concentration of 65wt% were mixed in a weight ratio of 1:100, and reacted at 160°C for 8 hours to obtain a reactant;

[0060] (3) The reactant obtained in step (2) is subjected to solid-liquid separation to obtain a solid product and a filtrate.

[0061] (4) Neutralize the solid product obtained in step (3) to about pH 7.0 with powdery potassium hydroxide.

[0062] (5) The solid finished product neutralized in step (4) is wet-process activated carbon-based potassium sulfate.

[0063] The test results are as follows:

[0064] Wet-process activated carbon-based potassium sulfate weight 643.7g (dry basis 487.8g), water content 24.22%, pH 6.9, activated carbon content 10.66%, iodine value 83, methylene blue 1.1ml, K 2 O content 48.26% (potassium sulfate 89.34%), SO 2 32.86%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com