A kind of preparation method of characteristic hexanitrohexaazaisowurtzitane

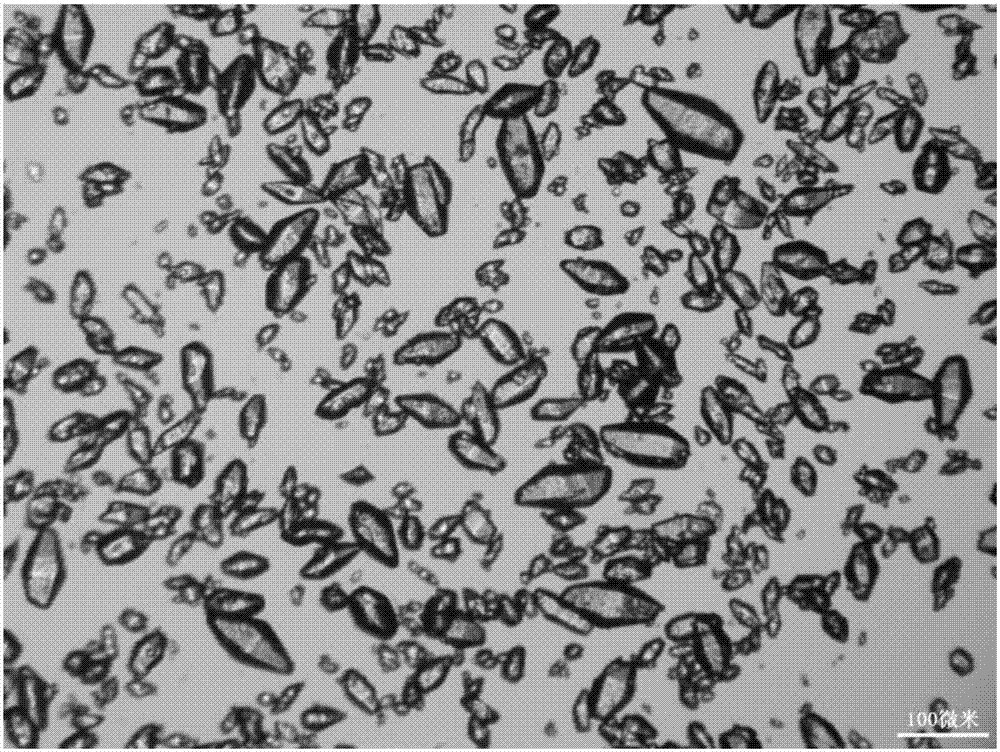

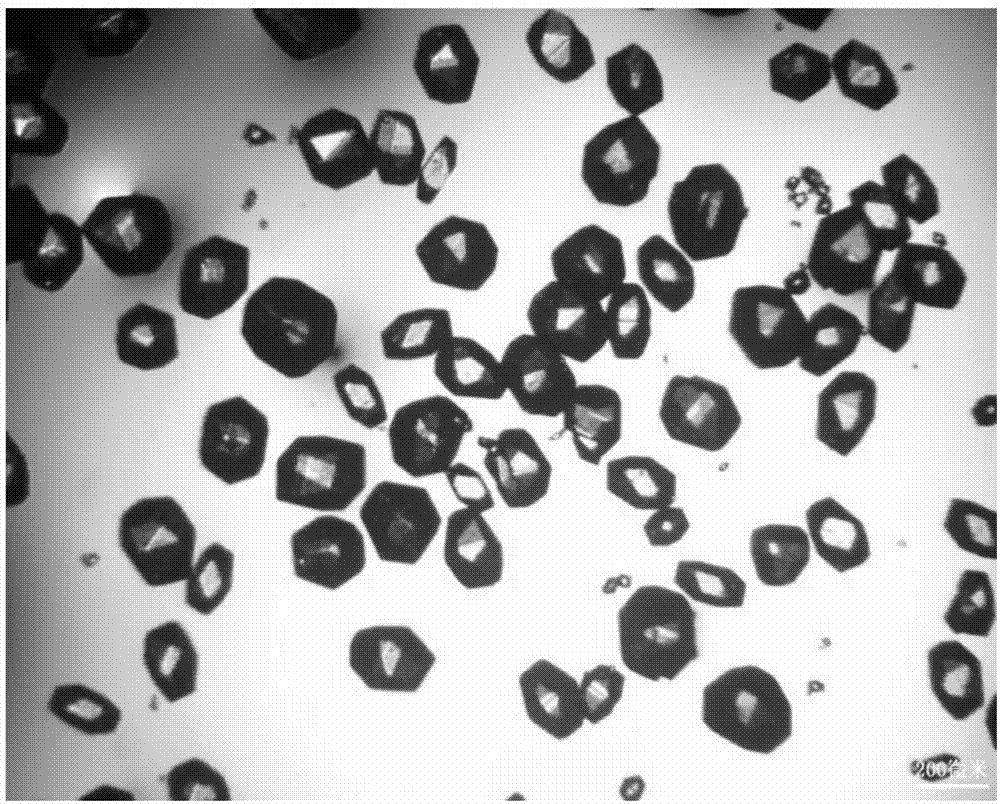

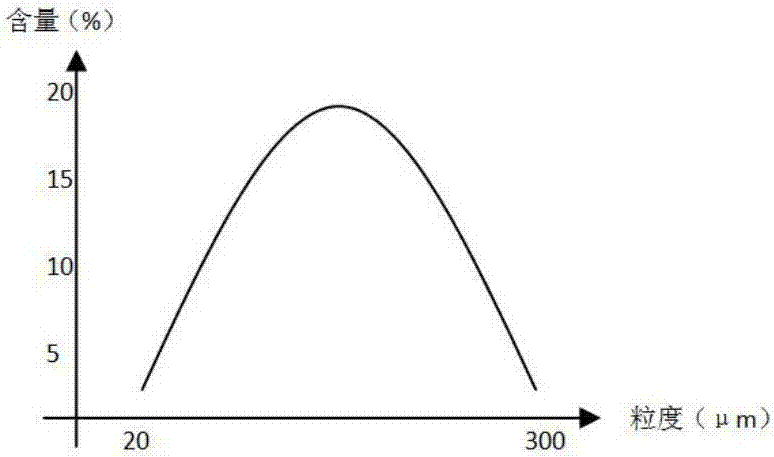

A technology of hexanitrohexaazane and isowurtzitane, which is applied in the field of preparation of special hexanitrohexaazaisowurtzitane, can solve the problems of wide particle size distribution, uneven particle size distribution, etc., and achieve crystal The effect of regular and smooth shape and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a method for preparing special hexanitrohexaazaisowurtzitane, which comprises the following steps: providing a hexanitrohexaazaisowurtzitane raw material solution; combining the hexanitrohexaazaisowurtzitane raw material The solution stream is added to the diluent and stirred to obtain the characteristic hexanitrohexaazaisowurtzitane; the particle size of the characteristic hexanitrohexaazaisowurtzitane is 100-110μm; the stirring speed is 500-600rpm ; The diluent is a low carbon alkane.

[0028] In the method provided by the present invention, the CL-20 solution stream is added to the low-carbon alkane diluent combined with the restriction of the stirring speed of 500-600rpm, which improves the mobility of the CL-20 solute in the solution and promotes the dissolution of the metastable crystal form. Thereby it is beneficial to stabilize the growth of the crystal form, and is beneficial to reduce the difference in the growth rate of the crystal...

Embodiment 1

[0046] Taking a 50-liter glass crystallization kettle as an example, the CL-20 is manufactured using the following steps:

[0047] 1. At room temperature, add 10kg ethyl acetate to the dissolving kettle;

[0048] 2. Under stirring conditions of 300rpm speed, add 4㎏ CL-20 and observe that all CL-20 is dissolved;

[0049] 3. Filter the dissolving liquid and add the dissolving liquid to the upper tank,

[0050] 3. Add 16kg of n-octane into the crystallization kettle, and raise the temperature to 42℃~45℃;

[0051] 4. Add the CL-20 solution at a speed of 1.0kg / min under 500rpm speed, continue to stir for 110min, and control the crystallization temperature to not be lower than 38℃;

[0052] 5. Discharge and drain the solvent in the filter layer;

[0053] 6. Place the crystalline material in a drying cabinet for drying, and dry it at 50°C until the moisture content is less than 0.10%;

[0054] 7. After the moisture content of the dried material is qualified, the mixed batch is packed;

[0055] 8. ...

Embodiment 2

[0062] Taking a 50-liter glass crystallization kettle as an example, the CL-20 is manufactured using the following steps:

[0063] 1. At room temperature, add 10kg ethyl acetate to the dissolving kettle;

[0064] 2. Under the stirring condition of 300rpm speed, add 4㎏ CL-20 and observe that all CL-20 is dissolved;

[0065] 3. Filter the dissolving liquid and add the dissolving liquid to the upper tank,

[0066] 3. Add 16kg of n-octane into the crystallization kettle and raise the temperature to 38℃;

[0067] 4. At 500rpm, add CL-20 solution at 1.0kg / min and continue stirring for 1h; then add 3.5kg n-octane at 1.kg / min and continue stirring at 700rpm for 1h to control the crystallization temperature Not lower than 38℃;

[0068] 5. Discharge and drain the solvent in the filter layer;

[0069] 6. Place the crystalline material in a drying cabinet for drying, and dry it at 50°C until the moisture content is less than 0.10%;

[0070] 7. After the moisture content of the dried material is quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com