Sulfonated polyether ether ketone capable of being used as crosslinking proton exchange membrane material and purpose thereof

A technology of sulfonated polyether ether ketone and proton exchange membrane, which is applied to fuel cell components, fuel cells, electrochemical generators, etc., and can solve the problems of difficult large-scale preparation, many steps, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

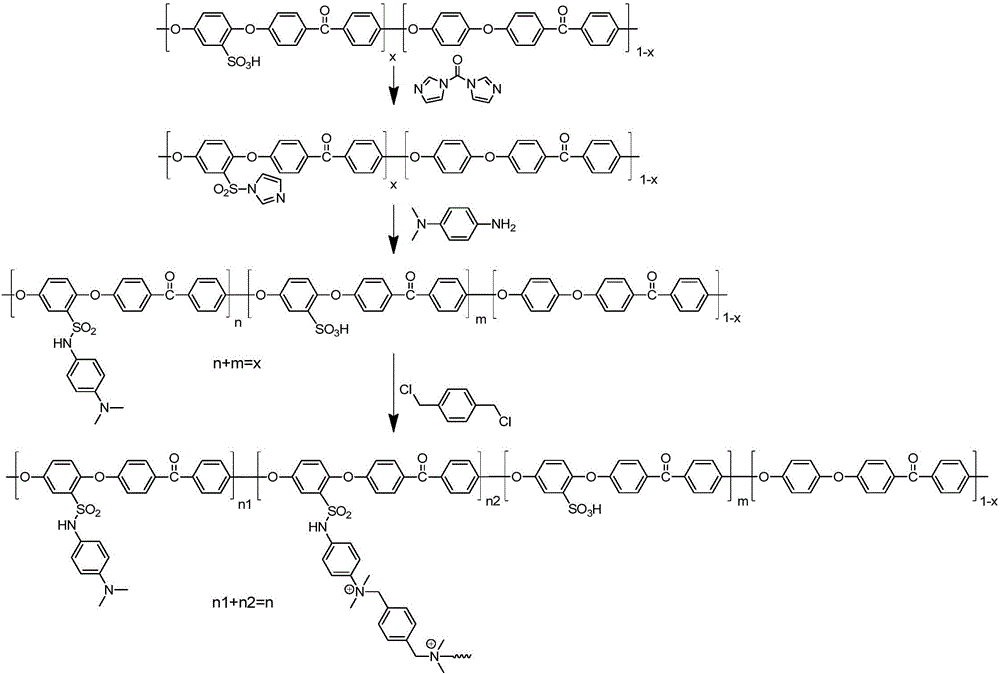

[0071] (1) Dissolve 10.00g of sulfonated polyetheretherketone (60% sulfonation degree) in 100mL of DMSO, add 1.46g of CDI, react at 50°C for 2h, then add 1.23g of N,N-dimethyl-p-phenylenediamine , after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 50%;

[0072] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.06 g of α,α’-dichloroxylene and stir at 25°C for 2 hours to obtain a casting solution;

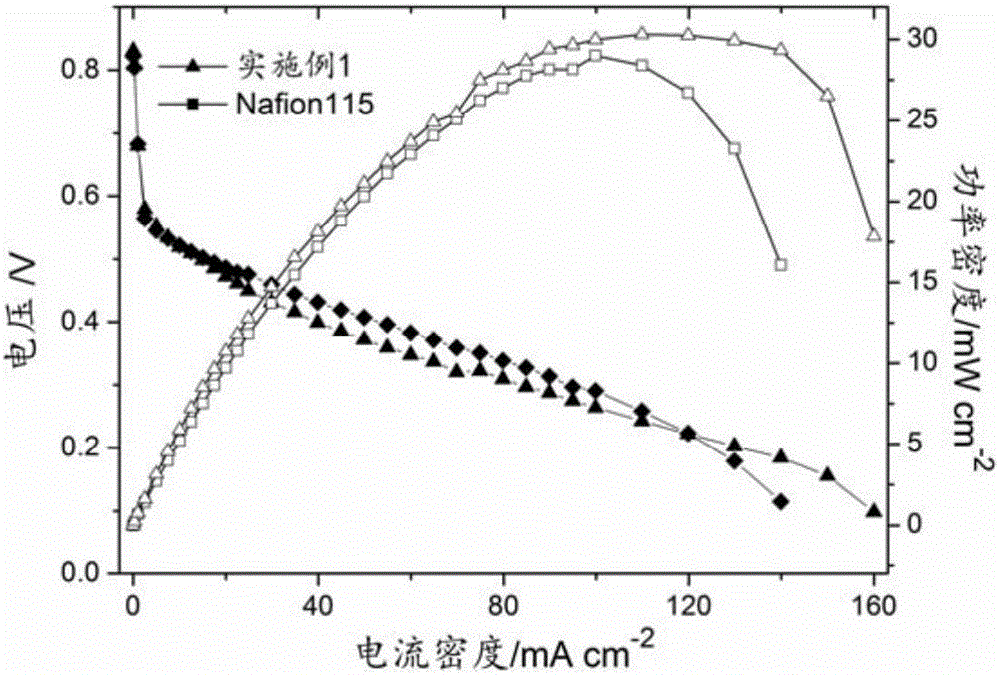

[0073] (3) Cast the above casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 120°C for heat treatment for 12 hours to obtain protons with a degree of crosslinking (covalent) of 10%. exchange membrane, the synthetic route is as follows figure 1 Shown, where x=0.6, n 1 =0.27, n 2 = 0....

Embodiment 2

[0075](1) Dissolve 10.00g of sulfonated polyether ether ketone (40% sulfonation degree) in 100mL DMSO, add 1.01g of CDI, react at 50°C for 2h, then add 0.64g of N,N-dimethyl-1,3 -Propylenediamine, after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 47%;

[0076] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.24 g of α,α’-dibromoxylene, stir at 25° C. for 2 h to obtain a casting solution;

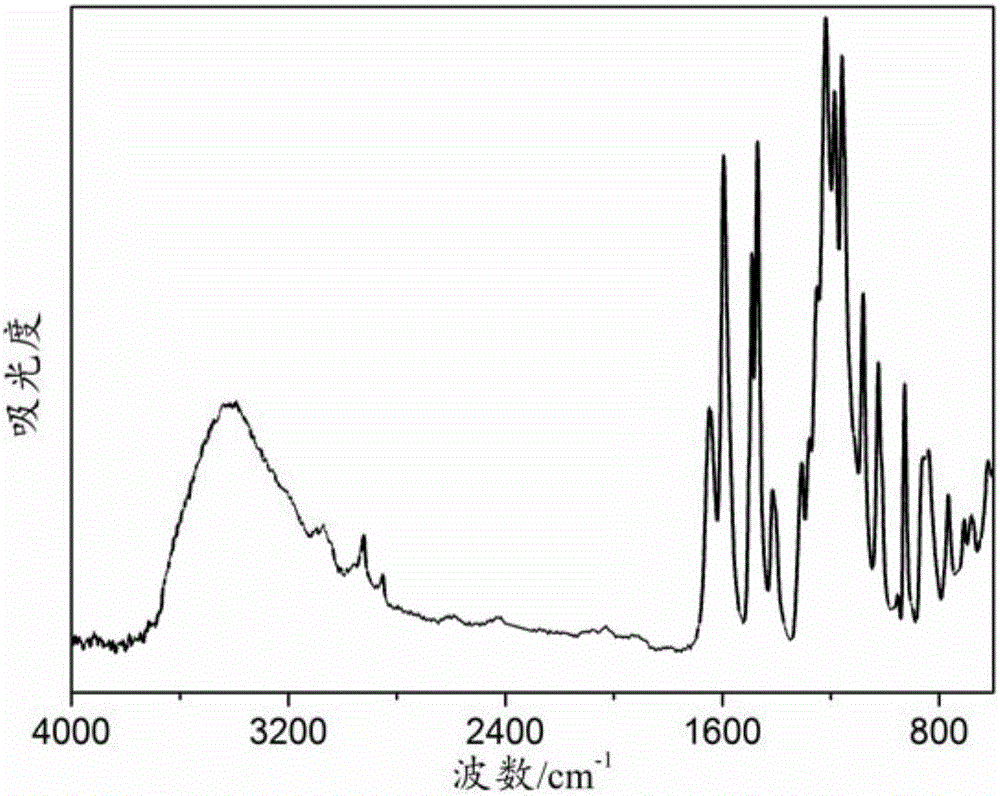

[0077] (3) Cast the above-mentioned casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 110°C for heat treatment for 12 hours to obtain a proton exchange membrane with a crosslinking degree of 40%. Infrared spectrum test shows that the polymer structure obtained in this embodiment contains ca...

Embodiment 3

[0079] (1) Dissolve 10.00g of sulfonated polyether ether ketone (sulfonation degree 60%) in 100mL DMSO, add 1.46g of CDI, react at 50°C for 2h, then add 1.05g of N,N-dimethyl-1,4 -Butanediamine, after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 42%;

[0080] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.44 g of α,α’-dibromoxylene, stir at 25° C. for 2 h to obtain a casting solution;

[0081] (3) Cast the above casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 100°C for heat treatment for 12 hours to obtain a proton exchange membrane with a crosslinking degree of 60%. Infrared spectrum test shows that the polymer structure obtained in this embodiment contains carbonyl, meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com