Soluble polyamideimide resin, and flexible metal-clad and flexible printed circuit boards obtained therefrom

A technology of polyamide-imide resin and metal-clad plate, which is applied in the direction of printed circuit, printed circuit, circuit substrate material, etc., can solve the problem of insufficient linear thermal expansion coefficient and achieve the effect of excellent thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

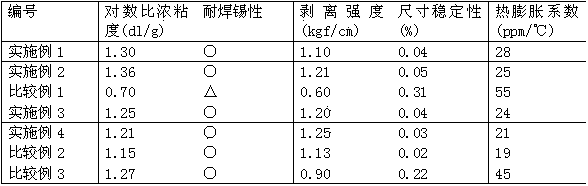

Examples

Embodiment 1

[0061] Add 192.0 g of TMA (1.0 mol, produced by Amoco Company in the United States, the source of raw materials is the same below), 26.4 g of 3,3'-dimethyl-4,4'-biphenyl diisocyanate (0.10 mol, Japan Soda Co., Ltd., the source of raw materials is the same below), diphenylmethane-4,4'-diisocyanate 225.0 g (0.90 mol, produced by Wanhua Chemical Group Co., Ltd., the source of raw materials is the same below), sodium methoxide 1.0 g (Sinopharm Group Produced by Chemical Reagent Co., Ltd., the source of raw materials is the same below), N-methylpyrrolidone 2.0 kg (produced by Mitsubishi Chemical Co., Ltd., the source of raw materials is the same below), after fully dissolved, heated to 80~150 °C under the protection of nitrogen flow, and stirred 3~8 hours. Finally, the logarithmic reduced viscosity of the obtained resin solution was 1.30 dL / g.

[0062] Using a stainless steel knife coater, coat the resin obtained above on the rough surface of 18 μm electrolytic copper foil (Suzhou...

Embodiment 2

[0064] Add 79.2 g (0.30 mol) of 3,3'-dimethyl-4,4'-biphenyl diisocyanate and 175.0 g (0.70 mol) of diphenylmethane-4,4'-diisocyanate into the reaction flask, and the rest Same as Example 1. Finally, the logarithmic reduced viscosity of the obtained resin solution was 1.36 dL / g.

Embodiment 3

[0068] Add 21.0 g (0.10 mol) of 1,5-naphthalene diisocyanate and 225.0 g (0.90 mol) of diphenylmethane-4,4'-diisocyanate into the reaction flask respectively. , and the rest are the same as in Example 1. Finally, the logarithmic reduced viscosity of the obtained resin solution was 1.25 dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com