Low temperature resistant and corrosion resistant marine cable sheath and preparation method thereof

A low-temperature-resistant technology for marine cables, applied in the field of low-temperature-resistant and corrosion-resistant marine cable sheaths and its preparation, can solve problems affecting the service life of cables, and achieve excellent physical and mechanical properties, good hydrophobicity, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

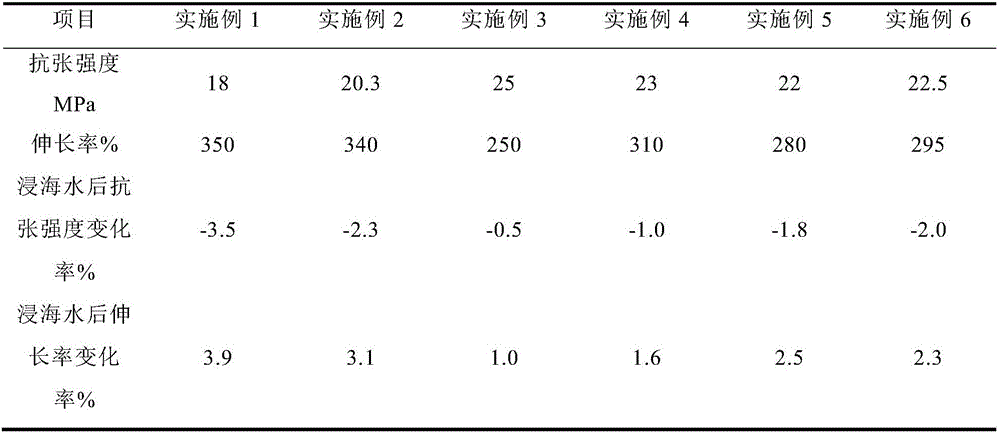

Examples

Embodiment 1

[0020] A low-temperature-resistant and corrosion-resistant marine cable sheath is made of the following raw materials in parts by weight:

[0021] 25 parts of fluorosilicone rubber, 20 parts of low temperature resistant silicone rubber, 15 parts of fluororubber, 15 parts of modified kaolin, 10 parts of plasticizer TOTM, 5 parts of polyvinyl chloride, 1 part of calcium zinc composite stabilizer, 5 parts of light magnesium oxide Parts, 3 parts of epoxy rapeseed oil, 2 parts of antioxidant 1010, 10 parts of carbon black, 2 parts of graphene microflakes.

[0022] The preparation method is as follows:

[0023] (1) Add 25 parts of fluorosilicone rubber, 20 parts of low-temperature resistant silicone rubber, and 15 parts of fluororubber into a high-speed kneader and knead at 50°C for 20 minutes, and continue to add 15 parts of modified kaolin, 10 parts of plasticizer TOTM, and 5 parts of polyvinyl chloride. 1 part, 1 part of calcium-zinc composite stabilizer, 5 parts of light magnes...

Embodiment 2

[0026] A low-temperature-resistant and corrosion-resistant marine cable sheath is made of the following raw materials in parts by weight:

[0027] 35 parts of fluorosilicone rubber, 30 parts of low temperature resistant silicone rubber, 20 parts of fluororubber, 25 parts of modified kaolin, 15 parts of plasticizer TOTM, 8 parts of polyvinyl chloride, 4 parts of calcium zinc composite stabilizer, 10 parts of light magnesium oxide Parts, 5 parts of epoxy rapeseed oil, 4 parts of antioxidant 1010, 20 parts of carbon black, 4 parts of graphene microflakes.

[0028] The preparation method is as follows:

[0029] (1) Add 35 parts of fluorosilicone rubber, 30 parts of low-temperature resistant silicone rubber, and 20 parts of fluororubber into a high-speed kneader for kneading, kneading at 50°C for 20 minutes, continue to add 25 parts of modified kaolin, 15 parts of plasticizer TOTM, polyvinyl chloride 8 parts, 4 parts of calcium-zinc composite stabilizer, 10 parts of light magnesiu...

Embodiment 3

[0032] A low-temperature-resistant and corrosion-resistant marine cable sheath is made of the following raw materials in parts by weight:

[0033] 30 parts of fluorosilicone rubber, 25 parts of low temperature resistant silicone rubber, 18 parts of fluororubber, 20 parts of modified kaolin, 13 parts of plasticizer TOTM, 7 parts of polyvinyl chloride, 3 parts of calcium zinc composite stabilizer, 8 parts of light magnesium oxide Parts, 4 parts of epoxy rapeseed oil, 3 parts of antioxidant 168, antioxidant 1010 weight ratio 1:2 composite antioxidant, 15 parts of carbon black, 3 parts of graphene microflakes.

[0034] The preparation method is as follows:

[0035] (1) Put 30 parts of fluorosilicone rubber, 25 parts of low-temperature resistant silicone rubber, and 18 parts of fluororubber into a high-speed kneader for kneading, kneading at 50°C for 20 minutes, continue to add 20 parts of modified kaolin, 13 parts of plasticizer TOTM, polyvinyl chloride 7 parts, 3 parts of calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com