Pressurizing electrolytic cell and intensified electrolysis method

An electrolytic cell and cell body technology, applied in the field of electrolysis, can solve the problems of no report, increase the production rate of active oxygen, etc., and achieve the effects of improving electrolysis efficiency, improving anodic oxidation process, and strengthening precipitation and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

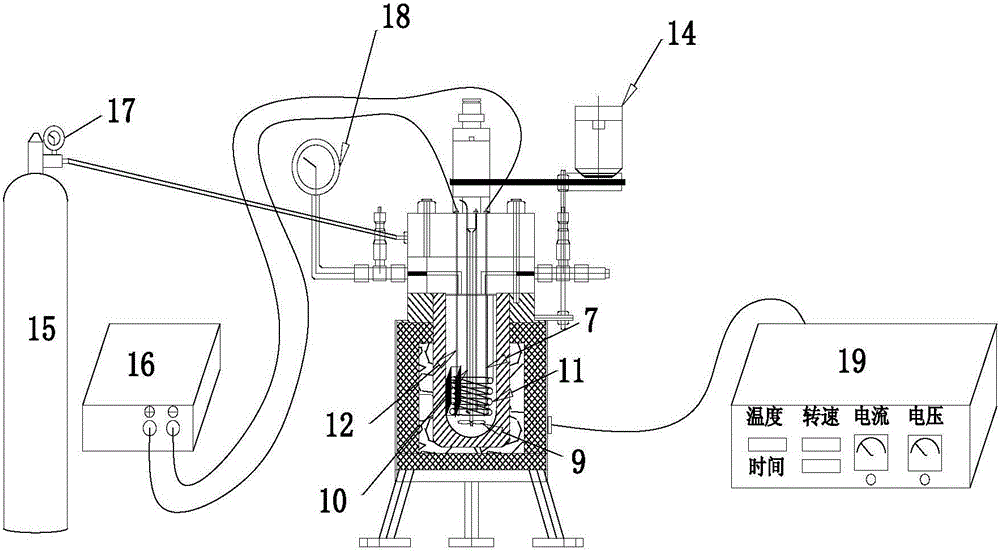

[0075] A pressurized electrolyzer comprising:

[0076] The reaction tank includes a tank body and a tank cover, the tank body and the tank cover are sealed and connected, and the tank cover is provided with a sealable negative connection hole, a positive connection hole and an air inlet;

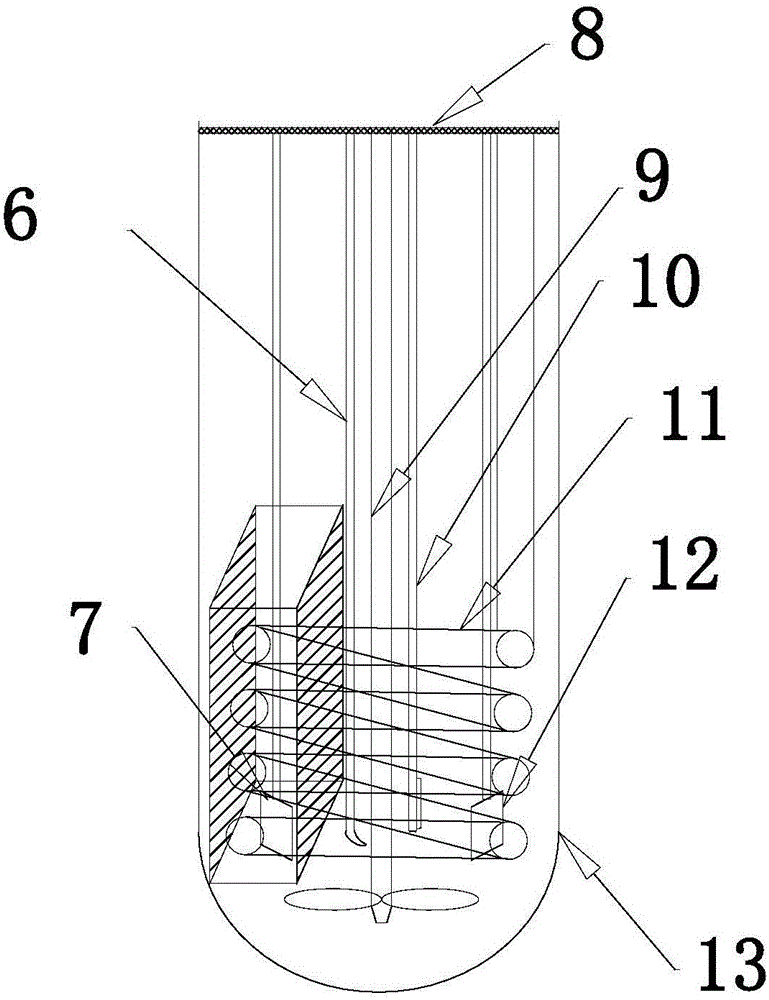

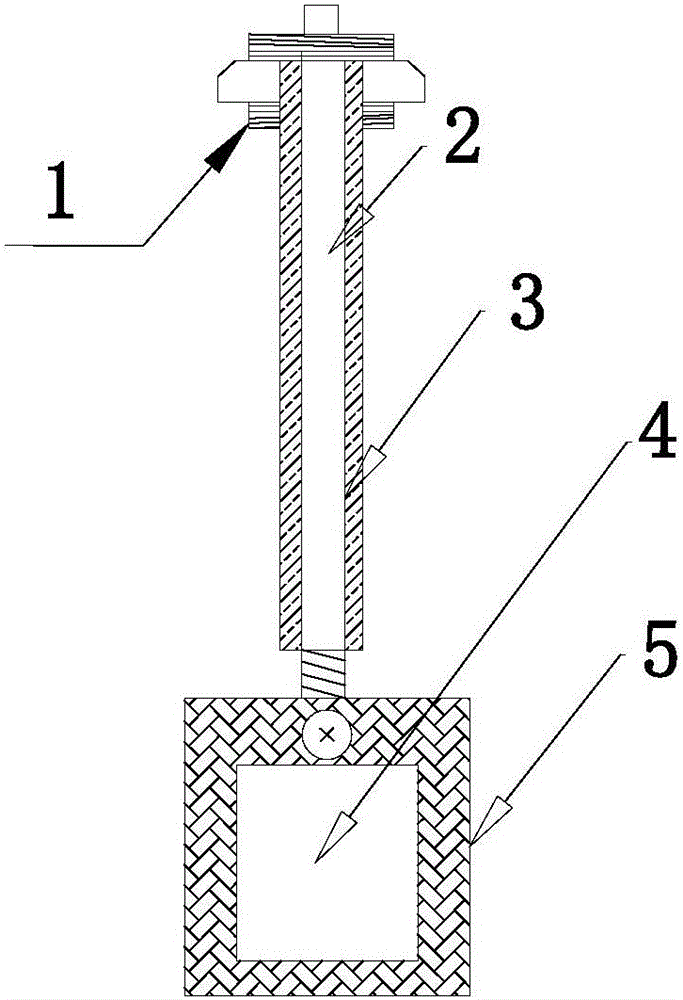

[0077] The electrodes placed in the reaction tank include a cathode 7 and an anode 12, the cathode 7 is connected to the negative pole of the power supply through the negative connection hole, and the anode 12 is connected to the positive pole of the power supply through the anode 12 connection hole;

[0078] The electrolytic diaphragm is arranged in the reaction tank and separates the cathode 7 and the anode 12;

[0079] The pressurizing device is used to increase the pressure in the reaction tank, including a gas supply device and / or a heating device, the gas outlet of the gas supply device communicates with the reaction tank through the air inlet, and the heating device is used to supply ...

Embodiment 2

[0081] A pressurized electrolyzer such as figure 1 shown. The pressurized electrolyzer comprises:

[0082] The reaction tank includes a tank body and a tank cover, the tank body and the tank cover are sealed and connected, and the tank cover is provided with a sealable negative connection hole, a positive connection hole and an air inlet;

[0083] The electrode placed in the reaction tank includes a cathode 7 and an anode 12 opposite to it, the cathode 7 is connected to the negative pole of the power supply through the negative connection hole, and the anode 12 is connected to the positive pole of the power supply through the anode 12 connection hole;

[0084] The ion membrane cover is wrapped on the cathode 7;

[0085] The heating device comprises an electric heating furnace 11, the reaction tank is placed in the electric heating furnace 11, the furnace core of the electric heating furnace 11 is a resistance wire furnace core, and the heating device surrounds the tank body ...

Embodiment 3

[0094] Use the pressure electrolyzer described in embodiment 2 to electrolyze coal water slurry, concrete steps are: take by weighing 40g sodium hydroxide, be dissolved in 1L distilled water, after it dissolves, add 20g coal wherein, after stirring, it is poured into In the pressurized electrolytic cell, the temperature of the solution in the pressurized electrolytic cell was kept at 100° C., the pressure was 0.1 MPa, no oxygen was introduced, the rotation speed of the stirring device was 200 r / min, and the treatment was performed for 120 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com