Sintered NdFeB magnet surface temporary protection organic coating and preparation method thereof

An organic coating and neodymium-iron-boron technology, applied in the manufacture of permanent magnets, coatings, magnetic materials, etc., can solve the problems of increasing the cost of three wastes, environmental pollution of phosphorus-containing wastewater, etc., to reduce porosity, improve mechanical properties, Improve the uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a temporary protective organic coating is prepared on the surface of the sintered NdFeB magnet according to the following steps:

[0036] (1) Pretreatment of sintered NdFeB magnets:

[0037] First, use HNO with a mass fraction of 25% 3 The solution pickled the sintered NdFeB magnets for 5 seconds, ultrasonically cleaned the pickled magnets, and cleaned the ultrasonically cleaned magnets with 3% HNO 3 Soak the sintered NdFeB magnet in the solution for 10s, perform the second ultrasonic cleaning on the soaked magnet, and immerse the magnet after the second ultrasonic cleaning in NaOH solution for 3 minutes; finally, take out the magnet from the NaOH solution Clean with alcohol, then dry with cold air for later use;

[0038] (2) Preparation of silyl organic alcohol solution:

[0039] Prepare γ-aminopropyltriethoxysilane, phenyltrimethoxysilane, deionized water, absolute ethanol, and ethylene glycol at a volume ratio of 1:1:0.8:3:3, using acetic acid ...

Embodiment 2

[0055] In this embodiment, a temporary protective organic coating is prepared on the surface of the sintered NdFeB magnet according to the following steps:

[0056] (1) Pretreatment of sintered NdFeB magnets:

[0057] With a mass fraction of 25% HNO 3 The solution pickled the sintered NdFeB magnets for 8s, ultrasonically cleaned the pickled magnets, and cleaned the ultrasonically cleaned magnets with 2% HNO 3 Soak the sintered NdFeB magnet in the solution for 15s, and then perform the second ultrasonic cleaning on the soaked magnet, and immerse the magnet after the second ultrasonic cleaning in NaOH solution for 4min; finally, take out the magnet from the NaOH solution Clean with alcohol, then dry with cold air for later use;

[0058] (2) Preparation of silyl organic alcohol solution:

[0059] Prepare γ-aminopropyltriethoxysilane, phenyltrimethoxysilane, deionized water, absolute ethanol, and ethylene glycol at a volume ratio of 2:1.5:1:4:4, using acetic acid Adjust the pH...

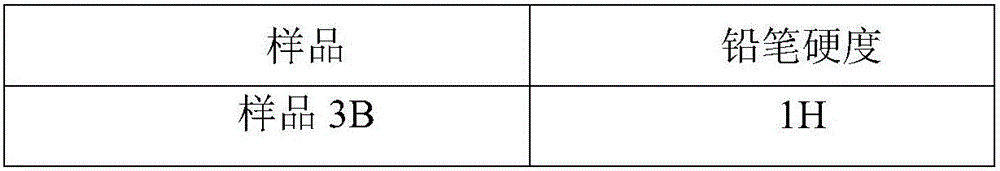

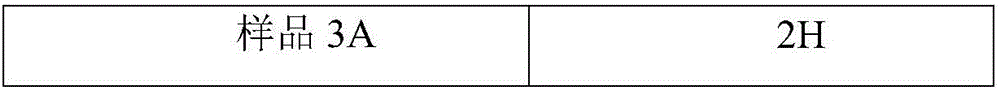

Embodiment 3

[0075] (1) Pretreatment of sintered NdFeB magnets:

[0076] First, use HNO with a mass fraction of 25% 3 The solution pickled the sintered NdFeB magnets for 10s, ultrasonically cleaned the pickled magnets, and cleaned the ultrasonically cleaned magnets with 1% HNO 3 Soak the sintered NdFeB magnet in the solution for 20s, perform the second ultrasonic cleaning on the soaked magnet, and immerse the magnet after the second ultrasonic cleaning in NaOH solution for 5 minutes; finally, take out the magnet from the NaOH solution Clean with alcohol, then dry with cold air for later use;

[0077] (2) Preparation of silyl organic alcohol solution:

[0078] Prepare γ-aminopropyltriethoxysilane, phenyltrimethoxysilane, deionized water, absolute ethanol, and ethylene glycol in a volume ratio of 3:2:1.2:5:6, using acetic acid Adjusting the pH value of the solution, stirring the silane-based organic alcohol solution for 20 hours, so that the components in the solution are evenly mixed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com