Adhesive composition, adhesive agent, and adhesive sheet

A composition, adhesive technology, applied in the direction of adhesive types, non-polymer organic compound adhesives, ester copolymer adhesives, etc., can solve problems such as lifting and peeling deterioration, air bubbles, durability decline, etc. , to achieve the effect of sufficient durability and light diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

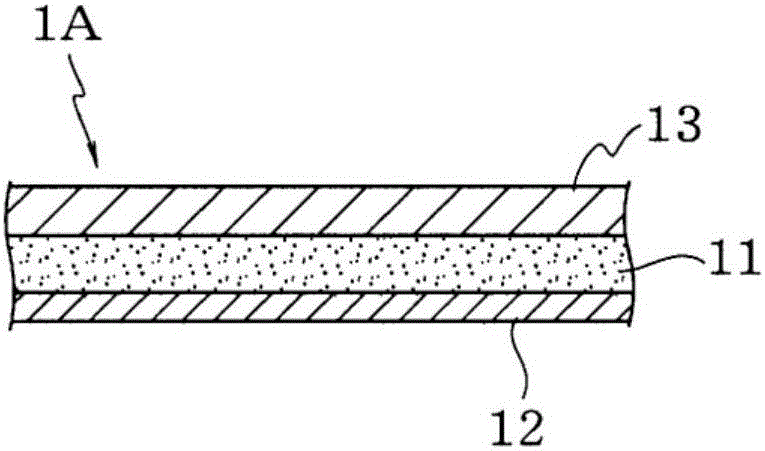

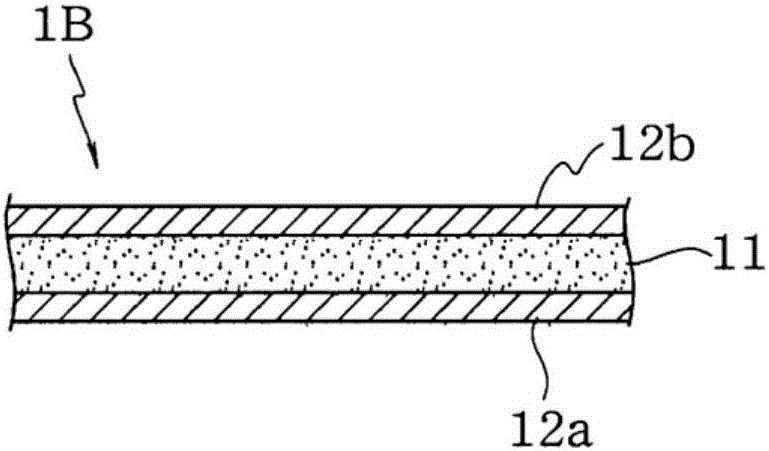

Image

Examples

preparation example Construction

[0079] 4. Preparation method of adhesive composition

[0080] The adhesive composition P can be prepared by mixing an active energy ray-curable adhesive component and light-diffusing fine particles. When the (meth)acrylate polymer (A) is contained in the active energy ray-curable adhesive component, the (meth)acrylate polymer (A) is prepared first, and then the active energy ray-curable compound (B) is added, and A crosslinking agent (C) and additives are added as needed.

[0081] The (meth)acrylate polymer (A) can be produced by superposing|polymerizing the mixture of the monomeric unit which comprises a polymer by a normal radical polymerization method. The (meth)acrylate polymer (A) can be superposed|polymerized by the solution polymerization method etc. using a polymerization initiator as needed. As a polymerization solvent, ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, etc. are mentioned, for example, and 2 or more type...

Embodiment 1

[0124] 1. Preparation of (meth)acrylate polymer

[0125] A (meth)acrylate polymer (A) was prepared by copolymerizing 94.5 parts by mass of n-butyl acrylate, 5 parts by mass of acrylic acid, and 0.5 parts by mass of 2-hydroxyethyl acrylate. As a result of measuring the molecular weight of this (meth)acrylate polymer (A) by the method mentioned later, it was 1.8 million weight average molecular weight.

[0126] 2. Preparation of Adhesive Composition

[0127] 83.5 parts by mass of the (meth)acrylate polymer (A) obtained in the above process (solid content conversion value; the same applies below), tris(acryloyloxyethyl)iso Cyanurate (manufactured by TOAGOSEI CO., LTD., product name "ARONIX M-315"; molecular weight 423) 15 parts by mass, and trimethylolpropane-modified toluene diisocyanate (Nippon Polyurethane Industry Co., Ltd., product name "CORONATE L") 0.3 parts by mass, a mixture of benzophenone and 1-hydroxycyclohexyl phenyl ketone as a photopolymerization initiator at a m...

Embodiment 2~11、 comparative example 1~6

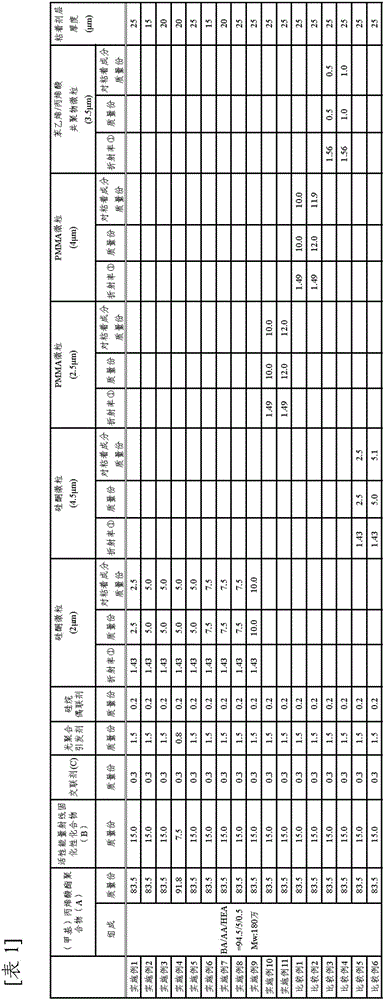

[0147] As shown in Table 1, the addition amount of (meth)acrylate polymer (A), active energy ray-curable compound (B) and photopolymerization initiator, the type and addition amount of light-diffusing fine particles, and the adhesive were changed. Except for the thickness of the layer, a polarizing plate with an adhesive layer was prepared in the same manner as in Example 1.

[0148] Here, the said weight average molecular weight (Mw) is the polystyrene equivalent weight average molecular weight measured by gel permeation chromatography (GPC) under the following conditions (GPC measurement).

[0149]

[0150] - GPC measurement device: HLC-8020 manufactured by Tosoh Corporation

[0151] · GPC column (passed in the following order): manufactured by Tosoh Corporation

[0152] TSK guard column HXL-H

[0153] TSK gel GMHXL (×2)

[0154] TSK gel G2000HXL

[0155] ·Measurement solvent: tetrahydrofuran

[0156] ·Measurement temperature: 40℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com