Cheese sauce preparation method

A cheese sauce and cheese technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of easy infection and deterioration, difficulty in exotic flavors, limited promotion and application, etc., to improve the flavor and taste of cheese, reduce production costs, and simplify production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

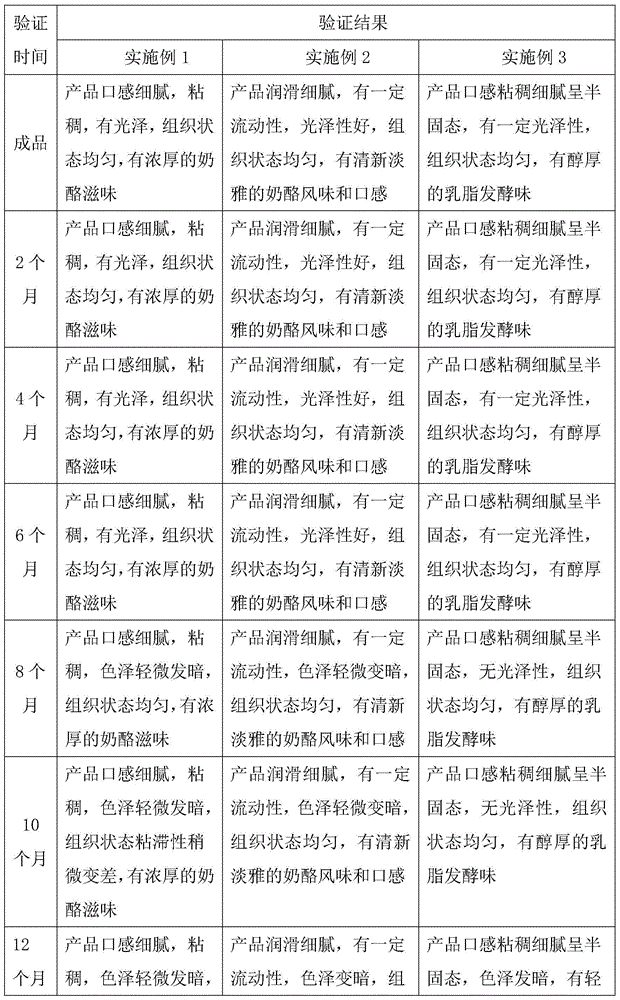

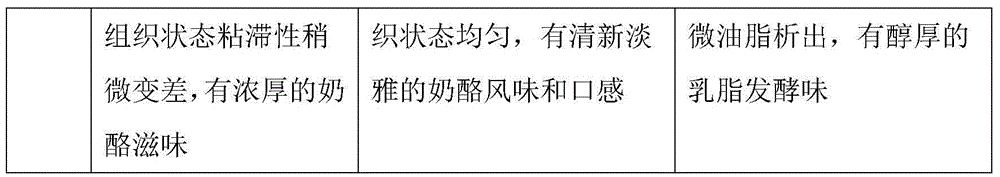

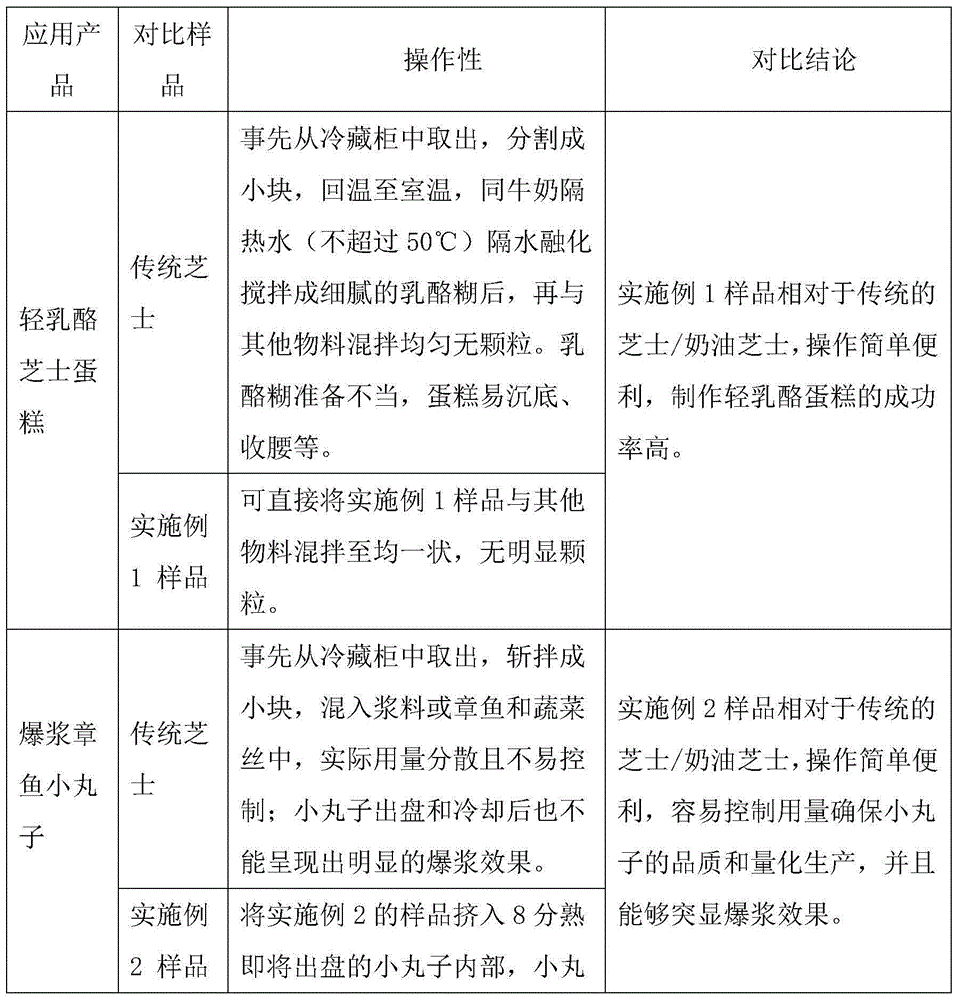

Examples

Embodiment 1

[0031] A method for preparing cheese sauce, which is obtained through the following steps:

[0032] (1) Thaw the cheese to 25°C in advance.

[0033] The moisture content of the cheese used in this embodiment is 40% (mass percentage), the fat content is 35% (mass percentage), pH 4.5, total acid 0.6g / 100ml, 10% (mass percentage) of soluble solids.

[0034] (2) Mix white granulated sugar: fermentation accelerator: water in a mass ratio of 5:3:90, and heat and dissolve at 40°C to obtain a fermentation accelerator liquid.

[0035] Fermentation accelerator used in the present invention also can be configured by mass fraction by following composition:

[0036] Strains 0.01%

[0037] Rennet 0.001%

[0038] Lipase 0.001%

[0039] The balance is emulsifier and dispersant.

[0040] Among them, the strains are preferably Lactococcus lactis subspecies and Lactococcus lactis subsp. lactis (diacetyl biological mutant) cultivated by Danish Chr. Hansen Company. The mass ratio of the two i...

Embodiment 2

[0050] A novel cheese sauce is prepared through the following steps:

[0051] (1) Thaw the cheese to 25°C in advance;

[0052] The moisture content of the cheese used in this embodiment is 55% (mass percentage), the fat content is 25% (mass percentage), pH 5.5, total acid 0.9g / 100ml, 7.5% (mass percentage) of soluble solids.

[0053] (2) White sugar: fermentation accelerator (CHR-HANSEN, Denmark): water was mixed at a mass ratio of 3:1:92, and heated and dissolved at 38°C to obtain a fermentation accelerator solution.

[0054] (3) Formulate milk powder: modified starch: fructose syrup: water at a mass ratio of 5:5:10:45 to make an additive solution, mix evenly in a jacketed pot and keep warm at 50°C for later use.

[0055] In order to improve the taste, an appropriate amount of edible salt and annatto or B-carotene can be added to the additive solution, the content of which is easily grasped by those skilled in the art according to the difference in taste.

[0056] The milk ...

Embodiment 3

[0064] A novel cheese sauce is prepared through the following steps:

[0065] (1) Thaw the cheese used in Example 1 and the cheese used in Example 2 at a mass ratio of 10:10 to 25° C. and use them together.

[0066] (2) Mix white granulated sugar: fermentation accelerator: water at a mass ratio of 7:2:95, heat and dissolve at 35°C to obtain a fermentation accelerator solution.

[0067] Fermentation accelerator in the present embodiment is made up of following components by mass fraction:

[0068] Strains 0.1%

[0069] Rennet 0.01%

[0070] Lipase 0.01%

[0071] The balance is emulsifier and dispersant mixed at a mass ratio of 1:1.

[0072] The bacterial classification is preferably a mixture of Lactococcus lactis subspecies, Lactococcus lactis subspecies lactis, Bifidobacterium longum and Bifidobacterium lactis in a mass ratio of 1:1:1:1 cultivated by Danish Chr. The dispersant is preferably modified starch (Taylor Company), and the emulsifier is preferably Span 40 (Sorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com