Wettability-guided preparation method of microcapsules and application of microcapsules

A technology of microcapsules and infiltration, applied in the field of preparation of microcapsules, can solve the problems of complex devices, difficult to construct, difficult to modify, etc., and achieves the effects of good control, simplified process and improved repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

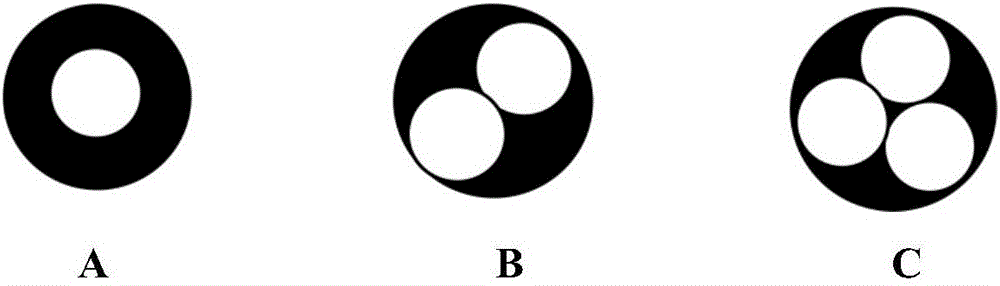

[0035] Example 1 Preparation of single-component ethoxylated trimethylolpropane triacrylate (ETPTA) microcapsules:

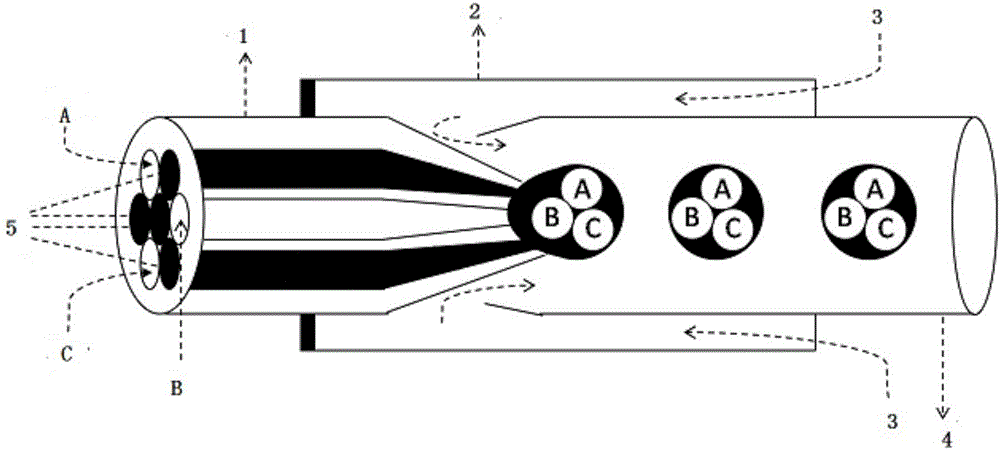

[0036] 1. Generation of ETPTA double emulsion: with figure 1 The device shown in the schematic diagram is similar, but the injection tube is a capillary tube with seven holes, and the injection tube is treated with a 2vol.%-10vol.% acetone solution of octadecyltrimethoxysilane; Assemble the microfluidic device with cover glass, sampling needle and quick-drying adhesive, the whole device is as follows: Figure 4Shown; The core solution is an aqueous solution containing 2wt% F108, and the shell solution is an ETPTA solution containing 1Wt% photoinitiator (HMPP). The continuous phase is methyl silicone oil KF-96 (0.65CS);

[0037] 2. The microfluidic device wraps the chip and all ETPTA pipes and syringes with black tape or tin foil to prevent the device from being blocked during UV curing; connect the syringe containing the three-phase solution to the correspond...

Embodiment 2

[0039] Example 2 Preparation of polyethylene glycol diacrylate (PEGDA) microcapsules loaded with oil-soluble dyes of three colors:

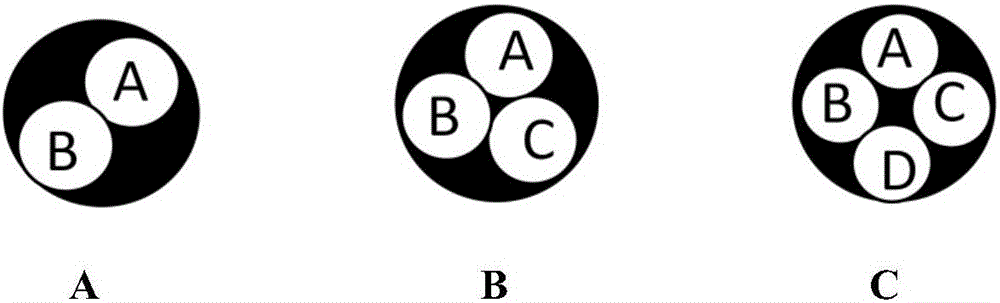

[0040] 1. Generation of PEGDA double emulsion: as figure 1 As shown, the injection tube is a capillary tube with seven holes, and the microfluidic device is assembled by using slide glass, cover glass, sampling needle and quick-drying glue. The inner core solutions (A, B, C) are silicone oil solutions of red, yellow, and blue oil-soluble dyes, respectively, and the shell solution is PEGDA hydrogel polymerization precursor solution containing 1wt% photoinitiator. The continuous phase is subunit silicone oil KF-96 (0.65CS). Connect the syringes filled with the biphasic solution to the corresponding glass capillary channels on the microfluidic chip.

[0041] . The microfluidic device wraps the chip and all PEGDA-through pipes and syringes with black tape or tinfoil to prevent the device from clogging during UV curing. Connect the syringes fille...

Embodiment 3

[0043] Example 3 Preparation of ethoxylated trimethylolpropane triacrylate (ETPTA) microcapsules carrying colloidal crystals with three different reflection peaks:

[0044] 1. Generation of ETPTA double emulsion: as figure 1 As shown, the injection tube is a capillary tube with seven holes, and the injection tube is hydrophobically treated with a 2 vol.%-10 vol.% acetone solution of octadecyltrimethoxysilane. Assemble the microfluidic device using glass slides, coverslips, sampling needles, and quick-drying adhesives. The inner core solution (A, B, C) is an aqueous solution of three kinds of silica nanoparticles with different particle sizes (10 vol.%, and contains 2wt% F108 as a surfactant), and the shell solution is a solution containing 1wt% light Initiator (HMPP) in ETPTA solution. The continuous phase is methyl silicone oil KF-96 (0.65CS).

[0045] . The microfluidic device is wrapped with black tape or tinfoil to wrap the chip and all the pipes and syringes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com