Methanol conversion to propylene all-silicon molecular sieve catalyst and preparation method thereof

A technology for all-silicon molecular sieve and methanol conversion, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of poor hydrothermal stability of catalysts, increased methane and coke content, and low P/E ratio of catalysts, etc. problem, achieve high methanol conversion activity, improve propylene selectivity, and good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

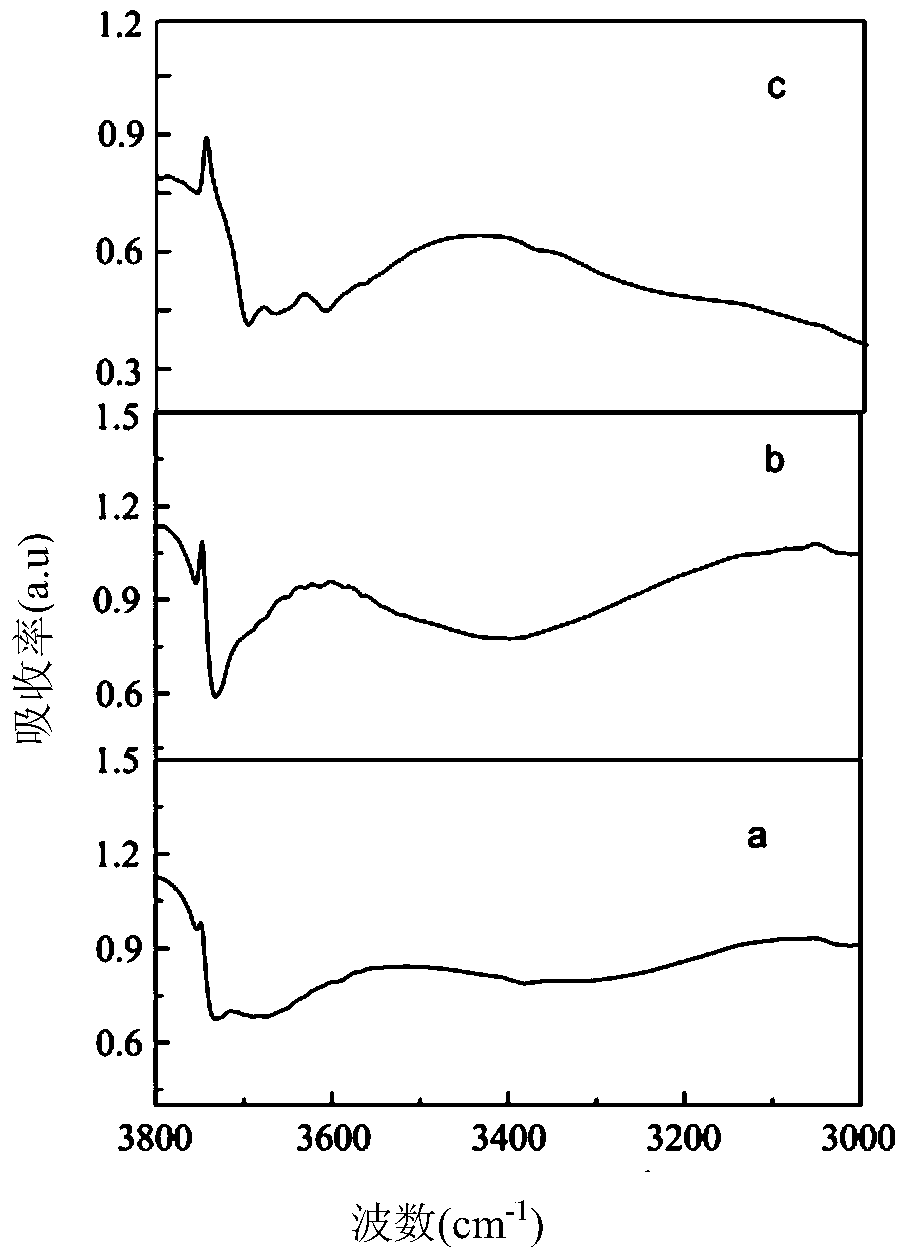

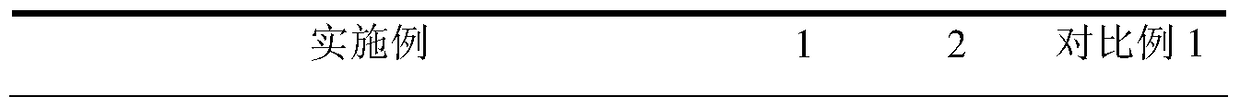

[0063] 15 g of all-silicon microporous ZSM-5 molecular sieves were calcined at 550° C. for 4 hours. Add 12g of ammonium nitrate and 150g of water to it, treat the above solution in a water bath at 80°C and strong stirring for 2h, suction filter until neutral, dry at 110°C for 2h, then repeat the above operation twice, each time the amount of ammonium nitrate Both are 0.8 times the amount of molecular sieves, and the amount of water is 10 times the mass of molecular sieves. Finally, it is roasted at 550 ° C for 3 hours to become a hydrogen-type all-silicon molecular sieve. After the molecular sieve was pressed into tablets, 1.2 g was taken for micro-reaction evaluation. Infrared detection ( figure 1 a), its 3200-3600cm -1 The peak area at 3740cm -1 The ratio of the peak areas at is 10:21. Evaluation results show that the conversion rate of methanol is 100wt%, and the carbon-based yield of propylene is 45.6%.

[0064] In the following examples, unless otherwise specified, t...

Embodiment 2

[0066] Mix 1.2g of sodium hydroxide and 300g of water into a solution with a concentration of 0.1mol / L, add 10g of all-silicon microporous ZSM-5 molecular sieve to the solution, stir in a water bath at 60°C for 4 hours, and filter until neutral. Dry at 110°C for 3h, then bake at 550°C for 4h. Take 5g of molecular sieve after the above operation, add 4g of ammonium nitrate and 50g of water to it, place the above solution in a water bath at 80°C for 2 hours, repeat the above operation twice, and finally roast at 550°C for 3 hours to obtain the desired hydrogen form All silica molecular sieve. Infrared detection ( figure 1 b), the molecular sieve 3200-3600cm -1 The peak area at 3740cm -1 The peak area ratio at 17:5. The evaluation results show that the conversion rate of methanol is 100wt%, and the carbon-based yield of propylene is 51.7C%.

Embodiment 3

[0068] Mix 35g all-silicon microporous H-ZSM-5 molecular sieve and 22.0g pseudo-boehmite evenly, add 15g nitric acid solution (4wt%) to it and knead, extrude with a mold with a diameter of 1.5mm, dry in the air, place Dry at 110°C for 4h, then bake at 600°C for 4h. Dissolve 2.0g of ammonium dihydrogen phosphate in 40g of water, impregnate the solution on the above catalyst by multiple impregnation, dry at 120°C for 1 hour after each impregnation, and finally roast at 600°C for 3 hours to obtain the final product The all-silicon molecular sieve catalyst, the evaluation result of the catalyst shows that the conversion rate of methanol is 100wt%, and the carbon-based yield of propylene is 50.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com