Method for directly growing hemimorphite zinc silicate on glass substrate

A technology of glass substrate and zinc silicate, applied in the direction of coating, etc., can solve problems such as complex reaction system, achieve the effect of simplifying reaction system, easy control, and less process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

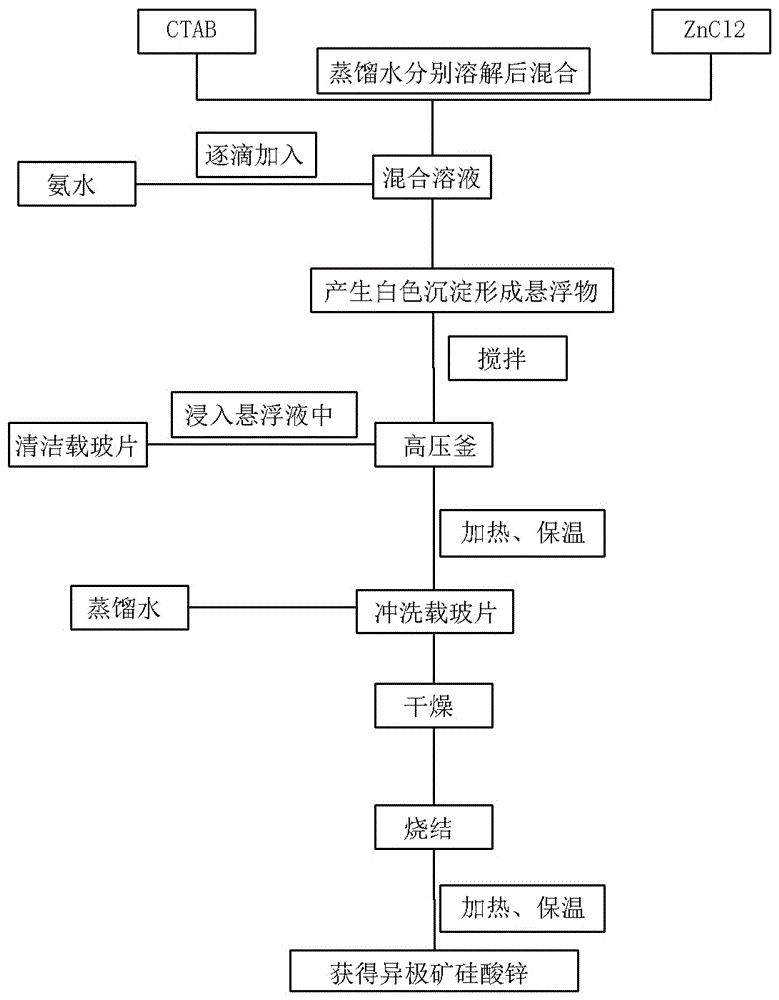

[0029] Such as figure 1 As shown, a method for directly growing hemimorphite zinc silicate on a glass substrate mainly includes the following steps:

[0030] Step 1, weigh 0.2724g of zinc chloride and 0.0227g of cetyltrimethylammonium bromide respectively, and dissolve them with 22ml of distilled water respectively.

[0031] Step 2: Pour the dissolved zinc chloride solution into the cetyltrimethylammonium bromide solution for mixing, and stir at room temperature for 20 minutes to obtain a completely dissolved, transparent and colorless mixed solution.

[0032] Step 3, add 1.6 g of ammonia water with a mass fraction of 25% to the transparent and colorless mixed solution obtained in step 2, and continue stirring at room temperature for 2 hours after a suspension appears.

[0033] In step 4, prepare the glass slide that has been ultrasonically cleaned with distilled water, cleaned with absolute ethanol, and dried as the substrate for the growth of zinc silicate.

[0034] Step 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com