A kind of environment-friendly low-rebound low-alkali liquid quick-setting agent and preparation method thereof

A low-rebound, environment-friendly technology, applied in the field of low-alkali liquid quick-setting agent for shotcrete and its preparation, can solve the problems of unfavorable promotion, high price, high dosage, etc., and achieve high adhesion, low rebound rate, The effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

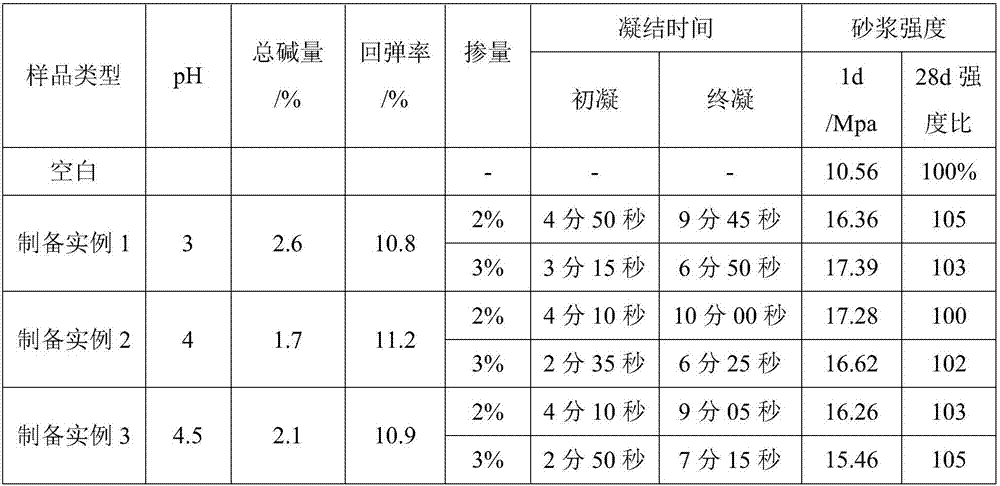

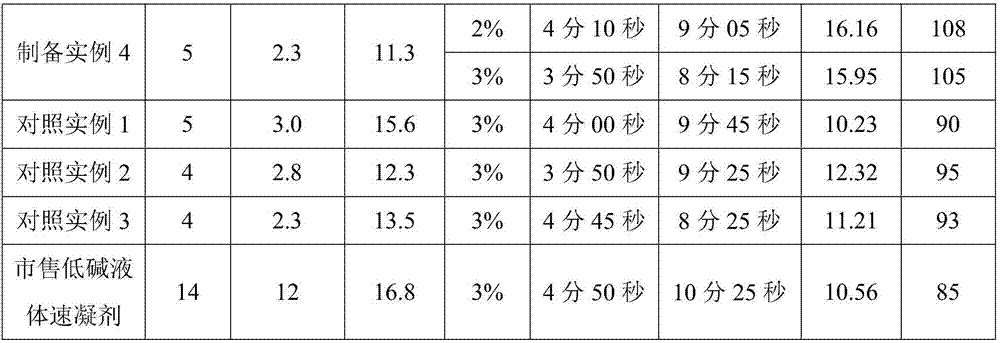

Examples

preparation Embodiment 1

[0029] (1) Preparation of modified polyaluminum sulfate solution

[0030] Dissolve 20g of polyaluminum sulfate (alumina mass percentage content of 35%) in 30g of water to form an aqueous solution of polyaluminum sulfate and dropwise into the bottom material of 18g of nano-alumina and 32g of aqueous solution, and carry out ultrasonic reaction, adding time 100min , and the reaction temperature was 75°C to obtain a stable and transparent solution of modified polyaluminum sulfate.

[0031] (2) Preparation of modified fluoride salt

[0032] Dissolve 30g of sodium fluoride in 70g of nano-silica dispersion, stir under high shear conditions for 2h, and the high speed shear should be at 2000S -1 , to obtain modified sodium fluoride.

[0033] (3) Preparation of modified alcohol amines

[0034] A mixture of 40 g of diethanolamine, 50 g of polyethylene polyamine and 10 g of ethyl orthosilicate was placed in a constant temperature water bath at 50° C. for 2 hours to react to obtain a mo...

preparation Embodiment 2

[0042] (1) Preparation of modified polyaluminum sulfate solution

[0043] Dissolve 35g polyaluminum sulfate (alumina mass percentage content of 33%) in 45g water to form a polyaluminum sulfate aqueous solution and add dropwise to the bottom material of 10g nano-alumina and 10g aqueous solution, and carry out ultrasonic reaction, dripping time 60min , the reaction temperature is 80 ℃, and the stable and transparent solution of modified polyaluminum sulfate is obtained.

[0044] (2) Preparation of modified fluoride salt

[0045] Dissolve 20g of sodium fluoroaluminate in 80g of nano-silica dispersion, stir for 3h under high shear conditions, high shear should be at 4000S -1 , to obtain modified sodium fluoroaluminate.

[0046] (3) Preparation of modified alcohol amines

[0047]A mixture of 60 g of triethanolamine, 37 g of polyethylene polyamine and 3 g of N,N-methylenebisacrylamide was placed in a constant temperature water bath at 40° C. for 3 hours to obtain a modified alcoh...

preparation Embodiment 3

[0055] (1) Preparation of modified polyaluminum sulfate solution

[0056] Dissolve 25g of polyaluminum sulfate (30% by mass of aluminum oxide) in 40g of water to form an aqueous solution of polyaluminum sulfate, add it dropwise to the base material of 15g of nano-alumina and 20g of aqueous solution, and perform ultrasonic reaction for 120 minutes , the reaction temperature is 85° C., and a stable transparent solution of modified polyaluminum sulfate is obtained.

[0057] (2) Preparation of modified fluoride salt

[0058] Dissolve 10g of sodium fluorosilicate in 90g of nano-silica dispersion, stir for 3 hours under high-shear conditions, and the high-speed shear should be at 6000S -1 , to obtain modified sodium fluorosilicate.

[0059] (3) Preparation of modified alcohol amine

[0060] A mixture of 45 g of diethanol monoisopropanolamine, 50 g of polyethylene polyamine and 5 g of diethylenetriamine was placed in a constant temperature water bath at 20° C. for 3.5 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com