Method for preparing halogenated polymer

A compound and copolymer technology, which is applied in the field of preparation of halogenated polymers, can solve the problems of high technical requirements for the preparation of aluminoxane, unsatisfactory, difficult preparation of initiator system, etc., to achieve high polymer yield and reduce energy Consumption, the effect of raising efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

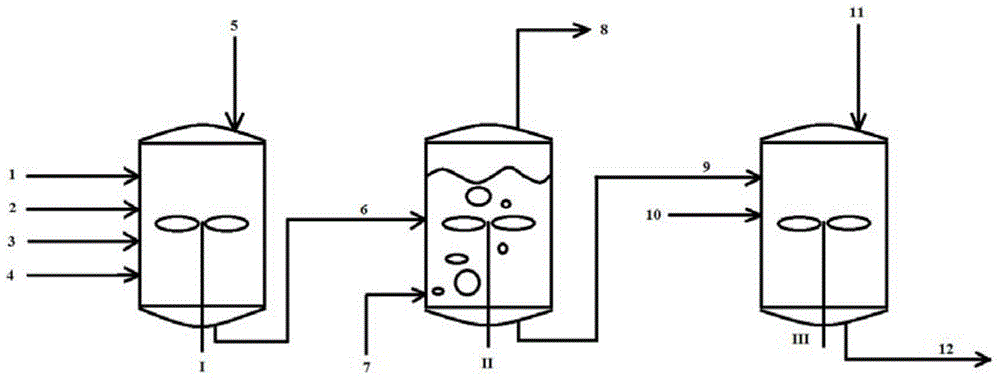

[0034] The invention provides a kind of preparation method of halogenated monoolefin-conjugated diene copolymer, the method comprises the following steps:

[0035] (1) Under cationic polymerization conditions, at least one monoolefin and at least one conjugated diene are contacted with each component in the initiator system in a polymerization solvent to obtain monoolefin-conjugated diene copolymer a solution, the polymerization solvent is composed of at least one first polymerization solvent and at least one second polymerization solvent, the first polymerization solvent is selected from halogenated alkanes, and the second polymerization solvent is selected from alkanes;

[0036] (2) Replace the halogenated alkane in the solution containing the monoolefin-conjugated diene copolymer with at least one replacement solvent and remove unreacted monomers to obtain a replacement solvent containing the monoolefin-conjugated diene copolymer After the solution, the replacement solvent ...

experiment example 1

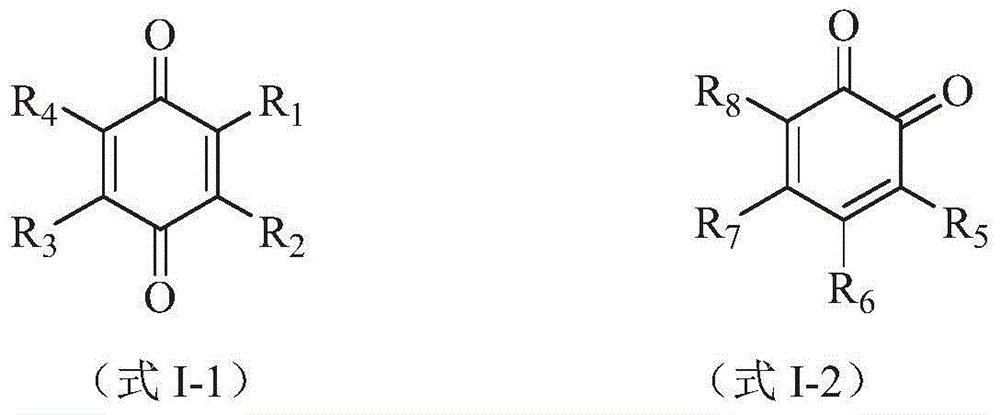

[0110] (1) 0.133g of chloro-p-benzoquinone was dissolved in 66.5g of dichloromethane solution to obtain a solution of chloro-p-benzoquinone. By weight, in this solution, the concentration of chloro-p-benzoquinone is 2000ppm.

[0111]At -80°C, 20mL of dichloromethane solution containing HCl (concentration: 0.0044mol / L), 1.5mL containing dichloroethylaluminum (concentration: 0.9mol / L) and L) n-hexane solution and 1 mL of the above-mentioned tetrachloro-p-benzoquinone solution were mixed uniformly and then aged at -80° C. for 15 minutes to obtain an initiator solution. By weight, in the initiator solution, the concentration of chloro-p-benzoquinone is 100ppm.

[0112] (2) Add 100 mL of methylene chloride pre-cooled to -60 °C, 80 mL of n-hexane pre-cooled to -60 °C, and 32 mL of isobutylene pre-cooled to -60 °C in a 500 mL glass reactor equipped with strong constant-speed stirring and 1 mL of isoprene pre-cooled to -20°C, and mix well. Add the initiator solution prepared in ste...

experiment example 2

[0117] Adopt the method identical with Experimental Example 1 to carry out polymerization, difference is, in the initiator solution that step (1) obtains, by weight, the concentration of tetrachloro-p-benzoquinone is 400ppm; In step (2), the initiator solution The addition amount was 20 mL, the temperature in the reactor was kept in the range of -60° C. to -65° C. during the dripping of the initiator solution and the polymerization reaction, and the polymerization reaction time was 15 minutes. The experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com