Gelling agent for gelled acid system and preparation and application thereof

A technology of gelling agent and gelling acid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., which can solve the problem of instability of gelling agent, inability to use high-temperature deep well reservoirs, and limited temperature resistance of gelling acid system and other problems, to achieve the effect of good temperature resistance, good practicability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0039] Examples 1-4: Preparation of gelling agent.

[0040] (1) Prepare 20% sodium hydroxide solution, and use the solution to neutralize the 2-acrylamido-2-methylpropanesulfonic acid in the three-necked flask.

[0041] (2) After the neutralization reaction is completed, lower the temperature in the three-neck flask to 10°C, add acryloyloxyethyltrimethylammonium chloride, acrylamide, etc., and water in sequence, and stir evenly.

[0042] (3) Nitrogen gas was passed into the neutralization three-necked bottle to drive away oxygen for 40 minutes to obtain a comonomer mixture.

[0043] (4) Put the comonomer mixture into the polymerization chamber in batches, add the set initiator, seal the reaction for 5 hours, and synthesize the jelly-state gelling agent.

[0044] (5) Take out the jelly-state gelling agent, cut and granulate, dry, pulverize, and sieve to obtain the finished product of dried gelling agent granules.

[0045]Examples 1-4 The composition of the comonomer mixture, ...

Embodiment 5-10

[0049] Examples 5-10: Preparation of gelled acid systems for oil and gas wells.

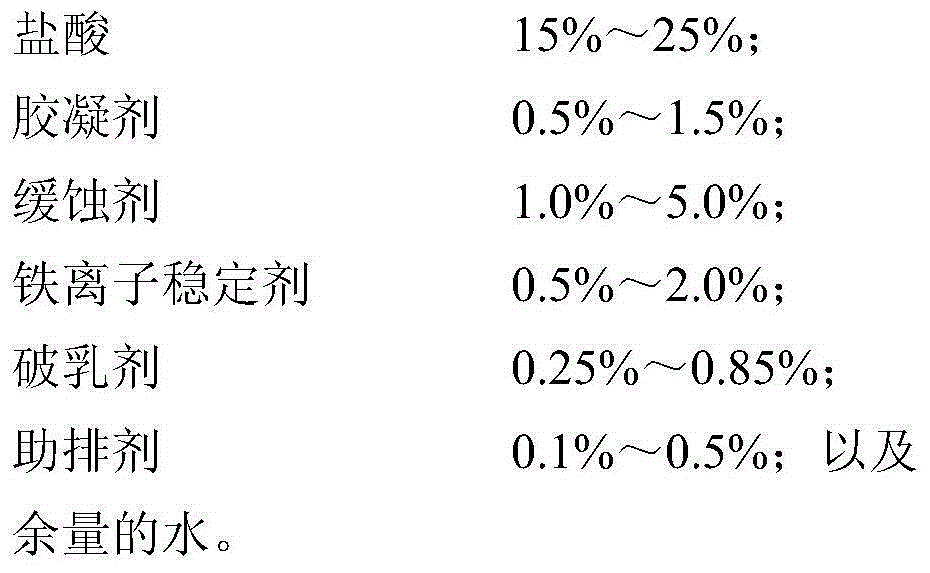

[0050] The gelling agents prepared in the above-mentioned Examples 1-4 were used to prepare cross-condensing acid systems for oil and gas wells. The preparation method was as follows: add part of the analytically pure hydrochloric acid to an appropriate amount of water and stir evenly to form a 15-25% solution Stir at 15-30°C, add the gelling agent evenly into the prepared hydrochloric acid solution, stop stirring for 0.5-1h, seal the container, let it stand for 3-5h to fully swell and mature evenly; continue stirring for 0.5 After ~1 hour, add multifunctional additives (corrosion inhibitor, iron ion stabilizer, demulsifier and drainage aid) according to the proportion, and after stirring evenly, the temperature-resistant gelling acid system for acidification and acid fracturing of oil and gas wells (that is, oil and gas well with gelled acid systems).

[0051] Determination of the rheology and ...

Embodiment 11

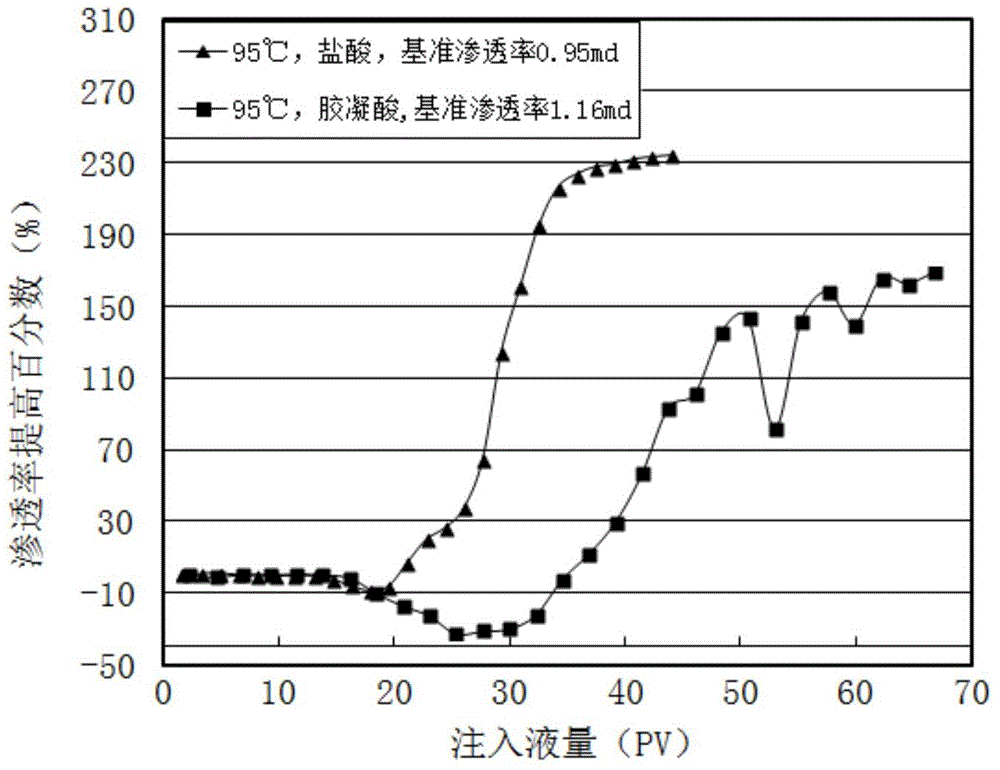

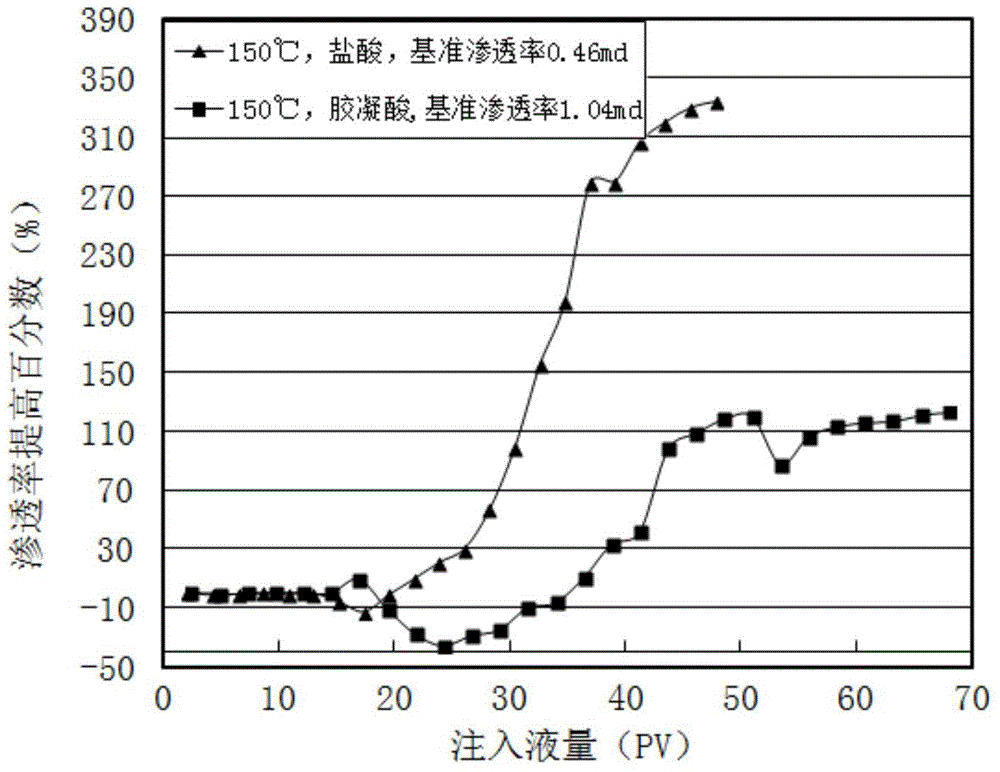

[0059] Example 11: Core flooding experiment under simulated formation conditions (95°C).

[0060] The gelled acid system prepared in Example 5 was subjected to a core displacement experiment under simulated formation conditions (95° C.) using a short core acidizing flow tester.

[0061] Experimental method: Through the core displacement experiment, record the pressure, flow rate at both ends of the core and the basic parameters of the core and fluid during the experiment, and calculate the change process and change of the core permeability before acidification, during acidification and after acidification according to Darcy's formula To analyze the improvement of the core permeability by the gelled acid system; at the same time, by injecting liquid paraffin into the acidified core, after the core cools, the paraffin solidifies in the pore channels of the core, leaving a model of the acid-rock reaction. Reflect the etched form and characteristics of acid and rock.

[0062] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com