Salt bath niobium infiltrating agent and niobium infiltrating method of lanthanum oxide (la2o3) catalyzed infiltration on the surface of titanium metal

A technology of metal titanium and lanthanum oxide, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high industrialization difficulty, complex process, poor flexibility, etc., and achieve low cost, simple operation, and improved The effect of niobium penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

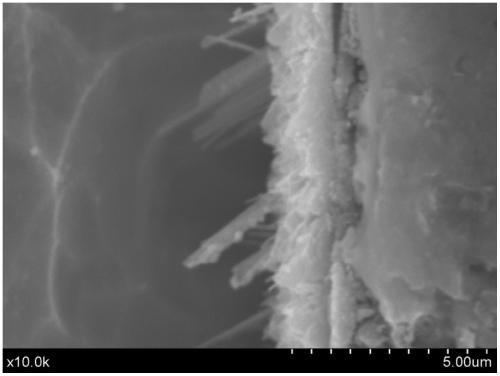

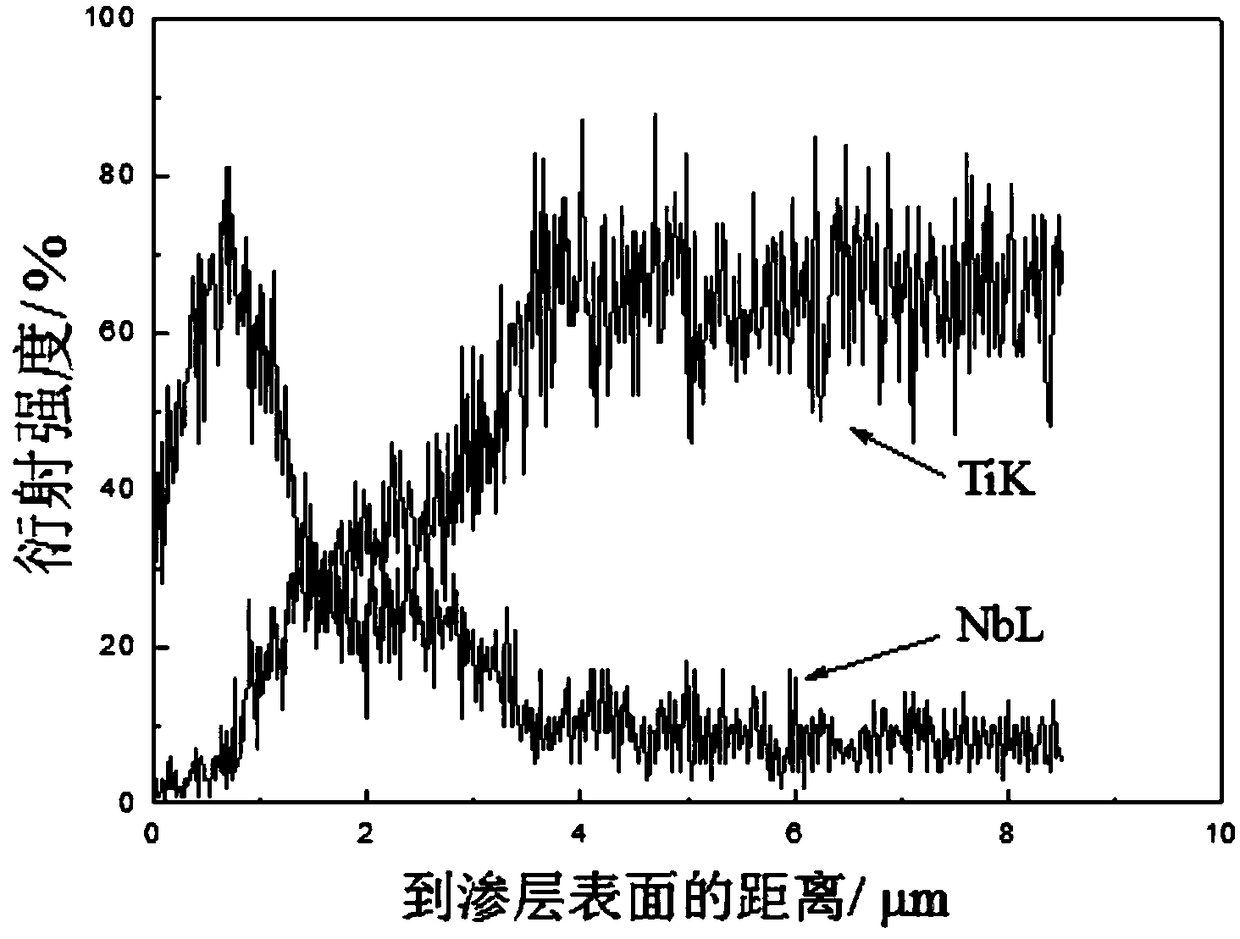

[0027] A metal titanium surface lanthanum oxide (La 2 o 3 ) Niobium infiltration method of salt bath infiltration niobium agent, which includes niobium infiltration preparation, workpiece pretreatment, niobium infiltration agent pretreatment, niobium infiltration and workpiece cleaning, wherein:

[0028] (1) Preparation of niobium infiltrating agent

[0029] Get 840 grams of anhydrous borax (Na 2 B 4 o 7 ), 100 grams of niobium oxide (Nb 2 o 5 ), 40 grams of silicon carbide (SiC) and 20 grams of lanthanum oxide (La 2 o 3 ) was mixed and dried at 125 °C for 50 minutes to obtain lanthanum oxide (La 2 o 3 ) Salt bath niobium infiltration agent for osmosis, set aside. The silicon carbide can be commercially available green and pure powder with a particle size of 150-200 mesh, the purity of niobium oxide is 99.5% or above, and the purity of lanthanum oxide is 99.99% or above.

[0030] (2) Workpiece pretreatment:

[0031] Cut the TC4 titanium alloy bar into 10 mm×12 mm×3...

Embodiment 2

[0038] The method is basically the same as in Example 1, except that the niobium infiltrating agent adopted does not add La 2 o 3 Catalyst, wherein the mass percentage of SiC is 6%.

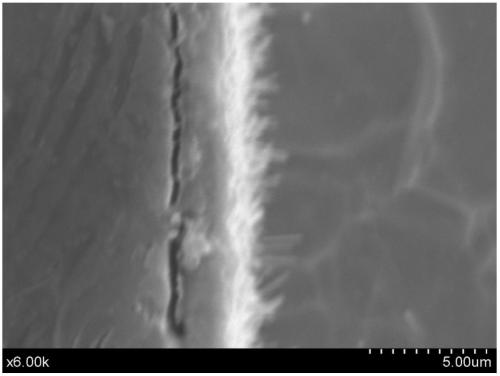

[0039] Test after taking out the sample. The thickness of the permeated layer is 1.6 μm ( figure 2 ), the microhardness of the outer layer of niobium infiltrated layer is 943.4 HV.

Embodiment 3

[0041] A metal titanium surface lanthanum oxide (La 2 o 3 ) Niobium infiltration method of salt bath infiltration niobium agent, which includes niobium infiltration preparation, workpiece pretreatment, niobium infiltration agent pretreatment, niobium infiltration and workpiece cleaning, wherein:

[0042] (1) Preparation of niobium infiltrating agent

[0043] Get 880 grams of anhydrous borax (Na 2 B 4 o 7 ), 80 grams of niobium oxide (Nb 2 o 5 ), 20 grams of silicon carbide (SiC) and 20 grams of lanthanum oxide (La 2 o 3 ) mixed and dried at 130 °C for 60 minutes to obtain lanthanum oxide (La 2 o 3 ) Salt bath niobium infiltration agent for osmosis, set aside. The silicon carbide can be commercially available green and pure powder with a particle size of 150-200 mesh, the purity of niobium oxide is 99.5% or above, and the purity of lanthanum oxide is 99.99% or above.

[0044] (2) Workpiece pretreatment:

[0045] Cut the TC4 titanium alloy bar into 10 mm×12 mm×3 mm p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com