Rare earth alkaline earth borate and preparation method and application

A borate and alkaline earth technology, applied in chemical instruments and methods, self-solidification method, self-melt liquid pulling method, etc., can solve the problems of expensive, volatile, and difficult TGG crystal raw materials for TGG crystals, and achieve a high price. The effect of low cost, simple synthesis, important economic and scientific research value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

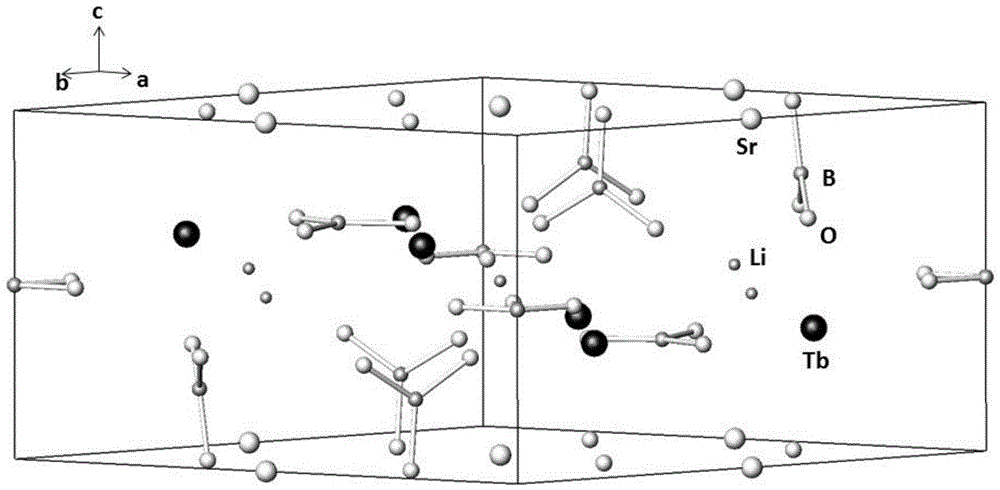

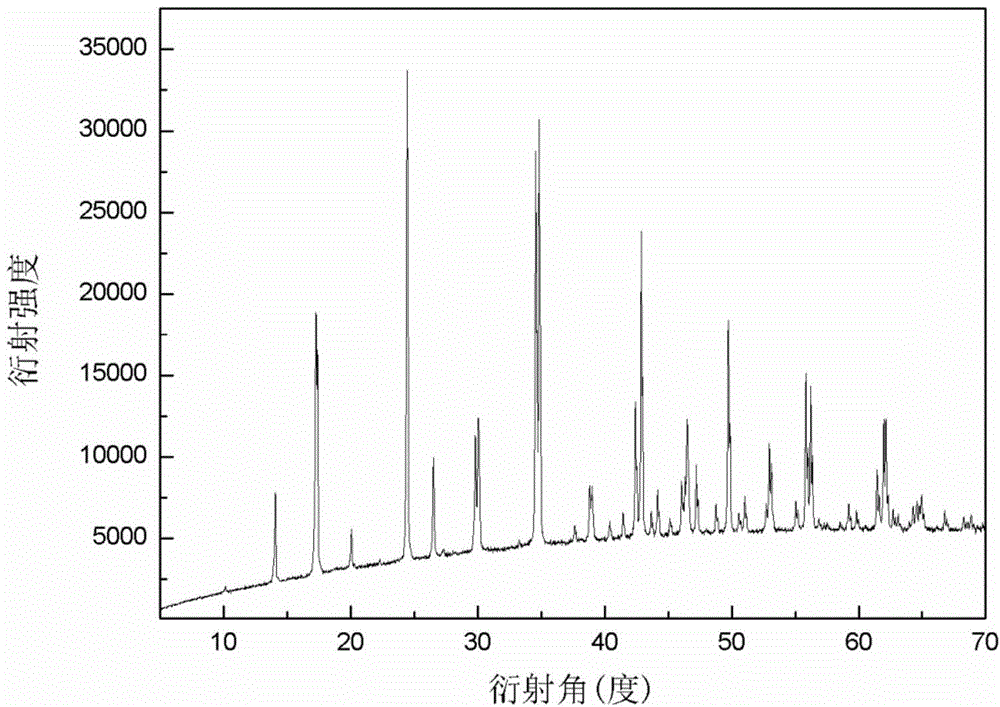

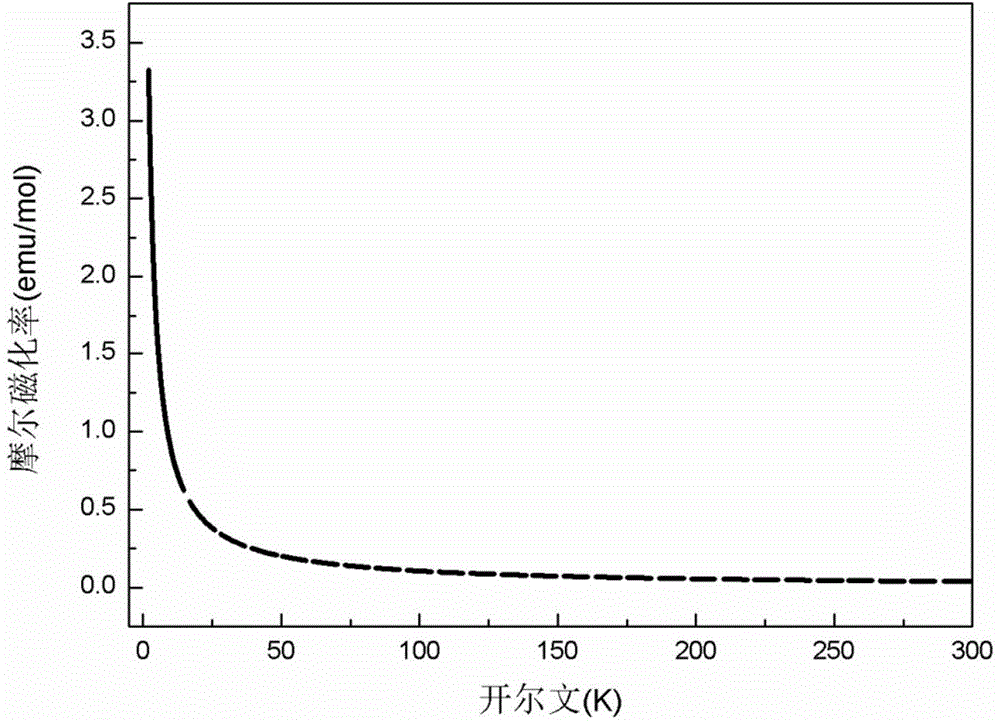

[0046] Synthesis of lithium strontium terbium borate (LiSrTb 2 (BO 3 ) 3 )Polycrystalline

[0047] Raw materials used (analytically pure): Tb 4 o 7 0.005mol, H 3 BO 3 0.03mol, SrCO 3 0.01mol, Li 2 CO 3 0.005mol.

[0048] The specific steps are as follows: after the above-mentioned raw materials are weighed, they are put into a mortar for mixing and grinding, then packed into a platinum crucible with a diameter of 10 mm × 10 mm, heated to 800° C., and repeatedly ground to obtain the lithium strontium terbium borate polycrystalline compound of the present invention ( LiSrTb 2 (BO3) 3 ).

Embodiment 2

[0050] Synthesis of lithium strontium europium borate (LiSrEu 2 (BO 3 ) 3 )Polycrystalline

[0051] Raw materials used (analytically pure): Eu 2 o 3 0.01mol, B 2 o 3 0.015mol, Sr(NO 3 ) 2 0.01mol, LiCl0.01mol.

[0052] The specific steps are as follows: after the above-mentioned raw materials are weighed, they are put into a mortar for mixing and grinding, then packed into a platinum crucible of φ10mm×10mm, heated to 800° C., and repeatedly ground to obtain the lithium strontium europium borate polycrystalline compound of the present invention ( LiSrEu 2 (BO3) 3 ).

Embodiment 3

[0054] Synthesis of lithium barium neodymium borate (LiBaNd) by high-temperature solid-state method 2 (BO 3 ) 3 )Polycrystalline

[0055] Raw materials used (analytically pure): Nd 2 o 3 0.02mol, H 3 BO 3 0.06mol, Ba(OH) 2 0.02mol, LiOH 0.02mol.

[0056] The specific steps are as follows: after the above-mentioned raw materials are weighed, put into a mortar and mix and grind, then pack into a platinum crucible of φ10mm×10mm, heat to 800° C., and grind repeatedly to obtain the polycrystalline lithium borate barium neodymium compound of the present invention ( LiBaNd 2 (BO3) 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com