Ultrasonic electrolysis based automatic decontamination system for removing radioactive surface contamination

A decontamination system and surface contamination technology, used in radioactive purification, nuclear engineering, etc., can solve the problems of difficult production, low decontamination efficiency, and unsatisfactory uranium decontamination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

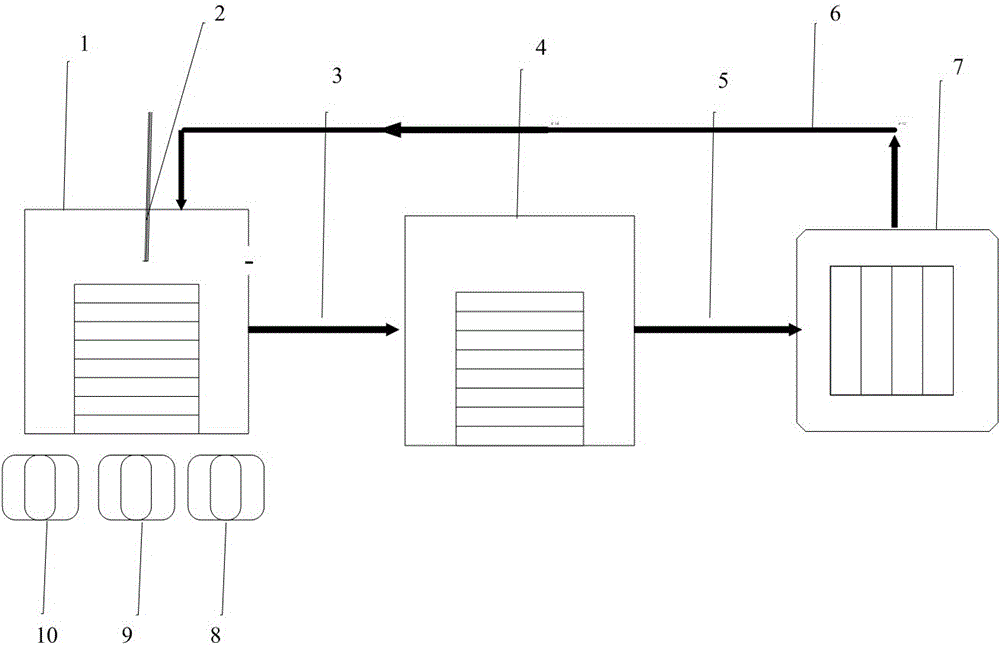

Method used

Image

Examples

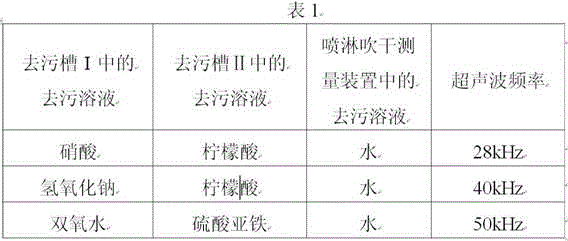

Embodiment 1

[0038] a. Place the object to be decontaminated in the decontamination tank Ⅰ and power on, the decontamination solution is nitric acid solution, and the surface of the object to be decontaminated is decontaminated by electrolysis;

[0039] b. The ultrasonic frequency of ultrasonic generator Ⅰ is 28kHz, the ultrasonic frequency of ultrasonic generator Ⅱ is 40kHz, and the ultrasonic frequency of ultrasonic generator Ⅲ is 50kHz. First turn on the ultrasonic generator Ⅰ, decontaminate by ultrasonic for 10min, then turn on the ultrasonic generator Ⅱ, decontaminate 10 minutes, after the decontamination is completed, turn on the ultrasonic generator III, decontaminate for 10 minutes, and the decontaminated object becomes the object Ⅰ;

[0040] c. The object I enters the decontamination tank II through the automatic conveyor belt I for heating and soaking, and the decontamination solution is citric acid to further remove the surface pollution of the object I and become the object II; ...

Embodiment 2

[0044] a. Place the object to be decontaminated in the decontamination tank Ⅰ and power on, the decontamination solution is sodium hydroxide solution, and the surface of the object to be decontaminated is decontaminated by electrolysis;

[0045] b. The ultrasonic frequency of ultrasonic generator Ⅰ is 28kHz, the ultrasonic frequency of ultrasonic generator Ⅱ is 40kHz, and the ultrasonic frequency of ultrasonic generator Ⅲ is 50kHz. First turn on the ultrasonic generator Ⅰ, decontaminate by ultrasonic for 10min, then turn on the ultrasonic generator Ⅱ, decontaminate 10 minutes, after the decontamination is completed, turn on the ultrasonic generator III, decontaminate for 10 minutes, and the decontaminated object becomes the object Ⅰ;

[0046] c. The object I enters the decontamination tank II through the automatic conveyor belt I for heating and soaking, and the decontamination solution is citric acid to further remove the surface pollution of the object I and become the object I...

Embodiment 3

[0050] a. Place the object to be decontaminated in the decontamination tank Ⅰ and power on, the decontamination solution is hydrogen peroxide solution, and the surface of the object to be decontaminated is decontaminated by electrolysis;

[0051] b. The ultrasonic frequency of ultrasonic generator Ⅰ is 28kHz, the ultrasonic frequency of ultrasonic generator Ⅱ is 40kHz, and the ultrasonic frequency of ultrasonic generator Ⅲ is 50kHz. First turn on the ultrasonic generator Ⅰ, decontaminate by ultrasonic for 10min, then turn on the ultrasonic generator Ⅱ, decontaminate 10 minutes, after the decontamination is completed, turn on the ultrasonic generator III, decontaminate for 10 minutes, and the decontaminated object becomes the object Ⅰ;

[0052] c. The object Ⅰ enters the decontamination tank Ⅱ through the automatic conveyor belt Ⅰ for heating and soaking. The decontamination solution is ferrous sulfate, and the surface pollution of the object Ⅰ is further removed to become the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com