ZIF-67-based synthetic method for constructing carbon nitride nano tube with super capacitance performance

A technology of ZIF-67 and synthesis method is applied in the field of preparation of supercapacitor energy storage materials to achieve the effects of easy implementation, good electrochemical activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Dissolve 0.328g of 2-methylimidazole and 0.249g of cobalt nitrate hexahydrate in 25mL of methanol under stirring at room temperature, and let stand at room temperature for 24 hours. After the mixture is centrifuged, it is washed with methanol and activated. Vacuum at 60°C After drying for 8 hours, ZIF-67 was obtained.

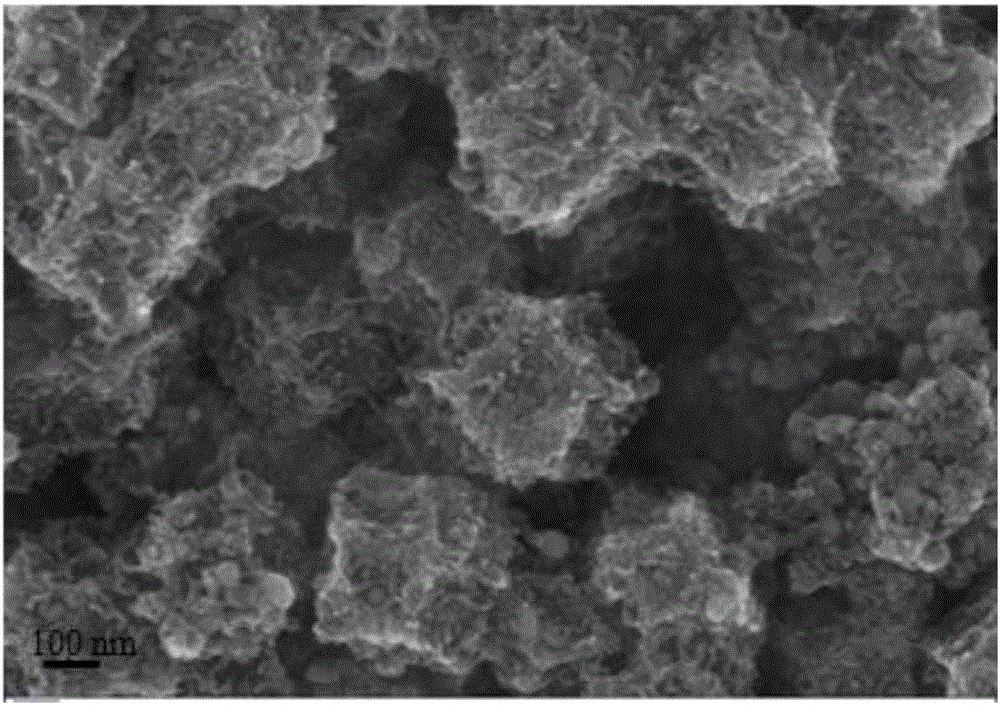

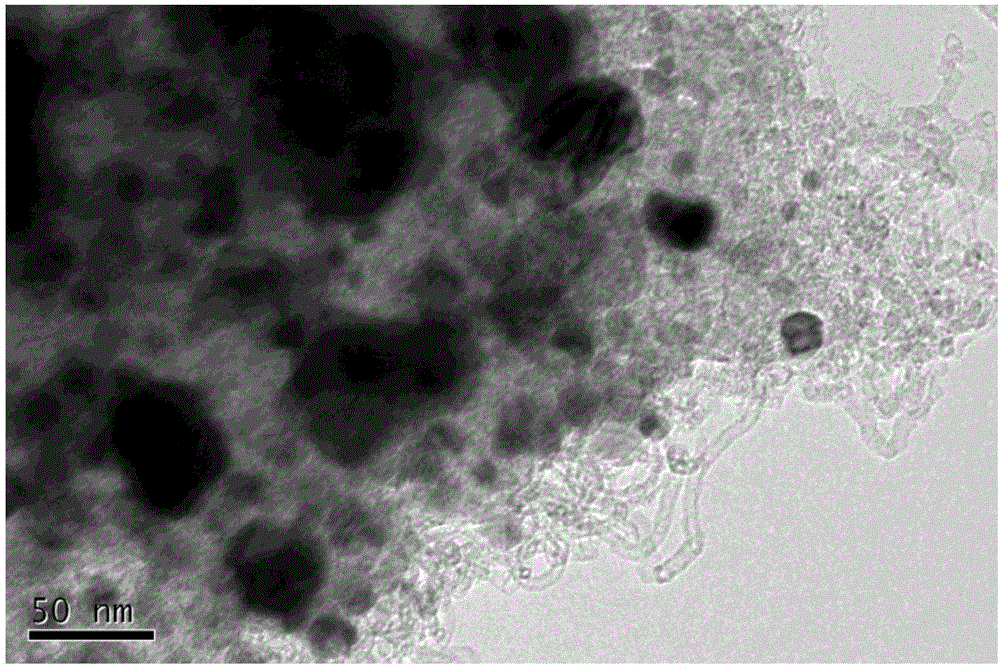

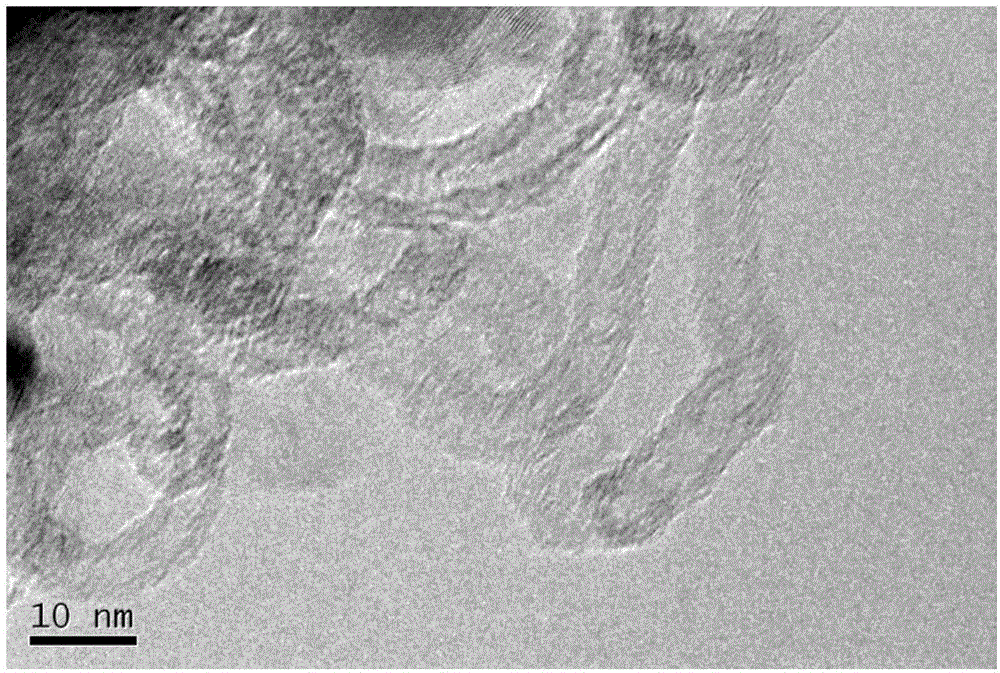

[0020] Step 2: Weigh 100 mg of ZIF-67 prepared in Step 1, place it in a mortar and grind it for 5 minutes, and under nitrogen protection, heat up to 800°C for 3 hours at a heating rate of 2°C / min to obtain cobalt-doped nitride carbon nanotubes.

[0021] Step 3: Weigh 25 mg of cobalt-doped carbon nitride nanotubes prepared in step 2, dissolve them in 30 mL of hydrochloric acid solution (12 mol / L) and acidify for 24 h, and wash the resulting precipitate with deionized water and absolute ethanol after centrifugation, Vacuum drying at 60°C for 8 hours to obtain high-purity carbon nitride nanotubes.

Embodiment 2

[0023] Step 1: Dissolve 0.328g of 2-methylimidazole and 0.249g of cobalt nitrate hexahydrate in 25mL of methanol under stirring at room temperature, and let stand at room temperature for 32 hours. After the mixture is centrifuged, it is washed with methanol and activated. Vacuum at 60°C After drying for 8 hours, ZIF-67 was obtained.

[0024] Step 2: Weigh 100 mg of ZIF-67 prepared in step 1, place it in a mortar and grind it for 5 minutes, and under nitrogen protection, heat up to 850°C for 3 hours at a heating rate of 2°C / min to obtain cobalt-doped nitride carbon nanotubes.

[0025] Step 3: Weigh 25 mg of cobalt-doped carbon nitride nanotubes prepared in step 2, dissolve them in 30 mL of hydrochloric acid solution (12 mol / L) and acidify for 32 h, and wash the resulting precipitate with deionized water and absolute ethanol after centrifugation, Vacuum drying at 60°C for 8 hours to obtain high-purity carbon nitride nanotubes.

[0026] The test result of the material that abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com