Visible-light-driven photocatalyst C@Bi2O3-BiOBr-BiOI as well as preparation method and application thereof in sterilization

A technology of visible light and catalyst, applied in the field of preparation of visible light catalyst, can solve the problems of unsatisfactory sterilization effect and long absorption wavelength, and achieve excellent sterilization ability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Preparation method of carbon nanospheres:

[0067] Dissolve 6 g of glucose in 60 mL of deionized water, conduct a hydrothermal reaction at 180°C for 24 hours, wash with distilled water and absolute ethanol three times, and dry at 80°C to obtain carbon nanospheres.

[0068] (2) C@Bi 2 o 3 The preparation method:

[0069] (1) 0.97g Bi(NO 3 ) 3 ·5H 2 O was stirred and dissolved in 17 mL of ethylene glycol solution, dispersed with 34 mL of absolute ethanol, added 72 mg of nano-carbon spheres, stirred vigorously for 40 min, and ultrasonically dispersed for 40 min, transferred the mixed solution to a polytetrafluoroethylene reactor, and heated it with water at 200 °C Reaction 10h;

[0070] (2) After cooling to room temperature, centrifuge, wash with water and ethanol three times, and dry in vacuum at 60°C for 3 hours to obtain C@Bi 2 o 3 .

[0071] (3) C@Bi 2 o 3 - Preparation method of BiOBr:

[0072] (1) 0.97g Bi(NO 3 ) 3 ·5H 2 O was stirred and dissolved...

Embodiment 2

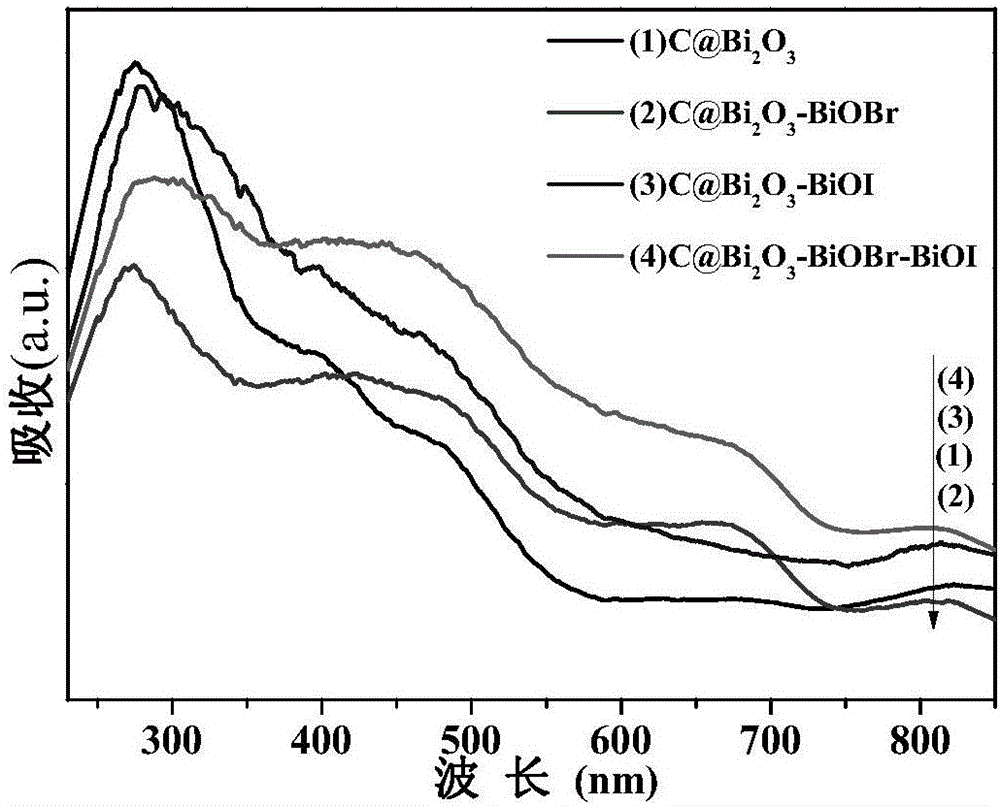

[0082] The photocatalyst C@Bi prepared in Example 1 2 o 3 、C@Bi 2 o 3 -BiOBr, C@Bi 2 o 3 -BiOI, C@Bi 2 o 3 -BiOBr-BiOI for UV-Vis diffuse reflectance scanning, get UV-vis-DRS contrast figure 1 .

[0083] Such as figure 1 , as can be seen from the figure, C@Bi 2 o 3 It has different degrees of absorption of ultraviolet light and visible light; C@Bi 2 o 3 -BiOBr has increased absorption in the visible region; C@Bi 2 o 3 -BiOI compared to C@Bi 2 o 3 , in a wide range of wavelengths, the absorption of light has increased; C@Bi 2 o 3 -BiOBr-BiOI has a large increase in the absorption of light in the visible light region, which is conducive to the increase of the visible light activity of the catalyst.

Embodiment 3

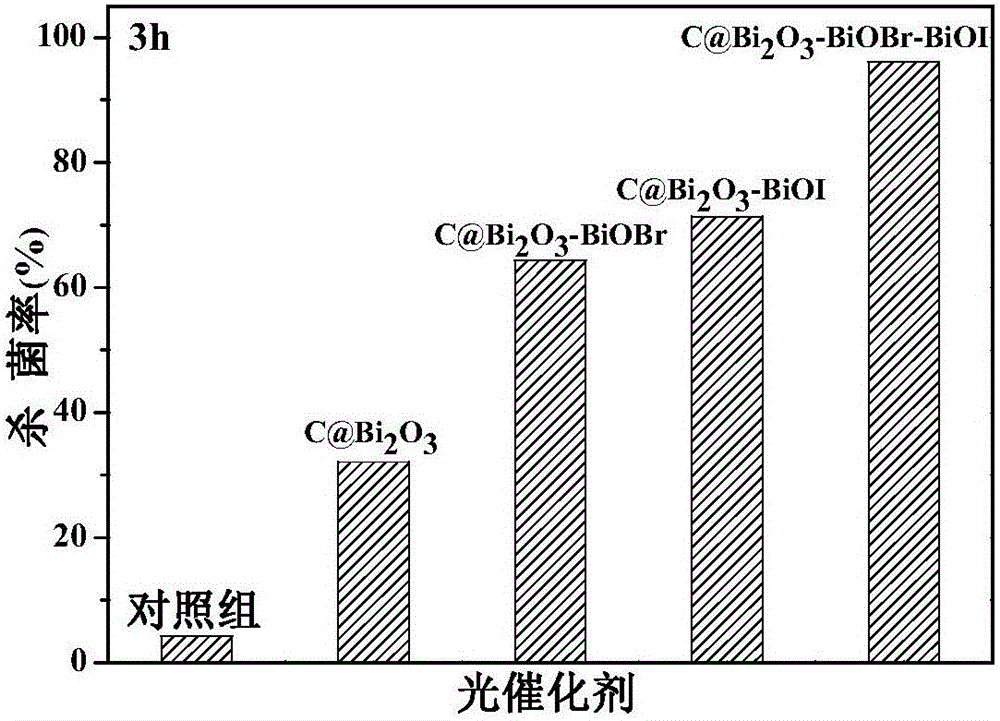

[0085] Adding C@Bi to the aqueous solution of Escherichia coli 2 o 3 -BiOBr-BiOI, irradiated with visible light for 3 hours, and incubated at room temperature and 100r / min for 1 hour with constant temperature shaking to obtain a bacterial suspension. Dilute the obtained bacterial suspension in sequence, and take 50 μL of the diluted solution and spread it on the agarose medium. , continue to cultivate in a constant temperature incubator for 24 hours, the temperature in the constant temperature incubator is 37°C, take out and count after the culture is over.

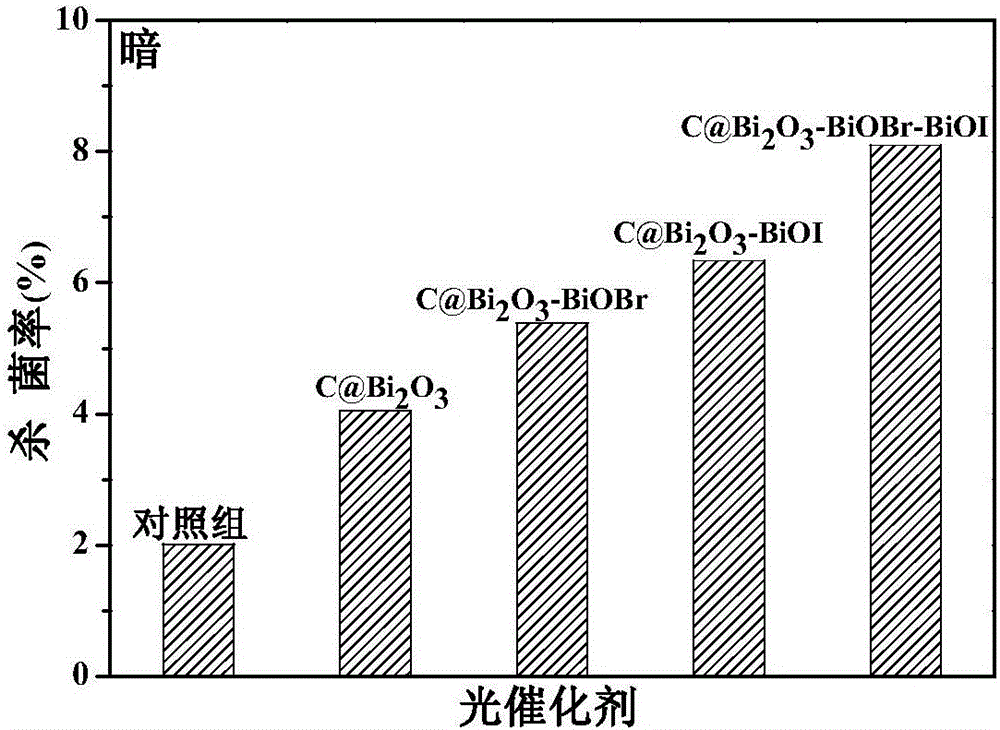

[0086] Change the photocatalyst to the photocatalyst C@Bi prepared in Example 1 2 o 3 、C@Bi 2 o 3 -BiOBr, C@Bi 2 o 3 -BiOI, C@Bi 2 o 3 -BiOBr-BiOI, while setting the control group without adding any catalyst, the results are shown in Figure 2(a). In addition, in order to eliminate the bactericidal effect of the photocatalyst itself under dark conditions, and to determine the bactericidal effect of light on the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com