Method for preparing high-temperature and strong alkali resistant type anion exchange resin

A technology of exchange resin and strong base, which is applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., and can solve the problems of harsh industrial production, easy to react with water, harsh production conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

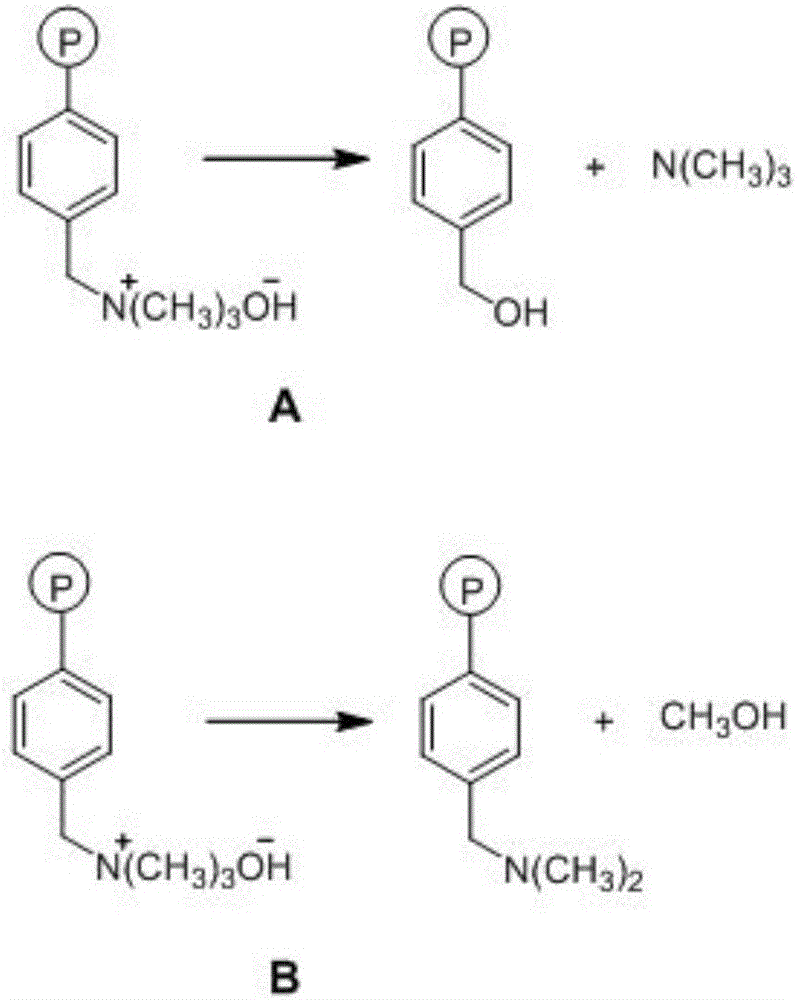

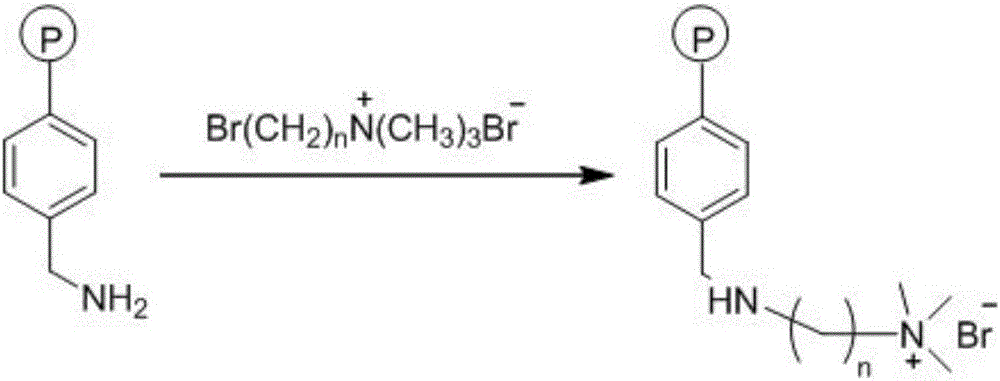

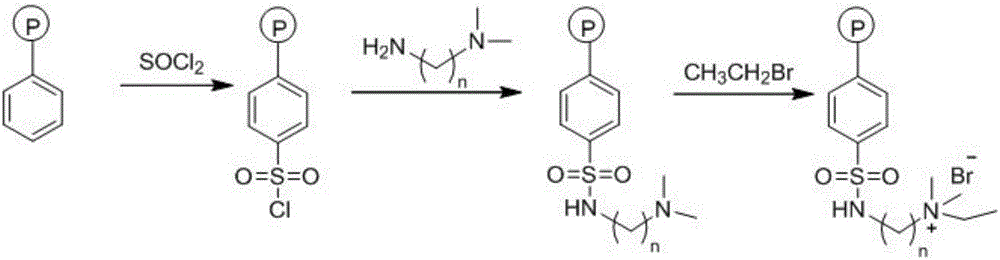

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 chlorine ball

[0030] Add 55.75 g of trisodium phosphate dodecahydrate and 1.54 L of water into a 3 L four-necked flask equipped with a stirrer, condenser and thermometer, and stir to raise the temperature to 80°C. Add 55.75 g of anhydrous calcium chloride at 50°C and stir for 10 minutes. At 60°C, a mixture of 4.95 g of hydroxyethyl cellulose and 20 g of sodium chloride was added. At 75°C, a mixture of 7.37 g calcium lignosulfonate and 20 g sodium chloride was added. At 80°C, 157.58 g of sodium chloride was added and stirred for 30 minutes. Then add a mixed solution of 699.68 g styrene, 17.94 g divinylbenzene (content 80%), 444.92 g porogen isobutanol and 7.17 g benzoyl peroxide, stir, adjust to a suitable particle size, and heat to 80°C for reaction After 1.5 hours, the temperature was raised to 82°C for 4 hours, and the temperature was raised to 88°C for 3 hours, and the temperature was continued to rise above 96°C, and the isobutan...

Embodiment 2

[0032] Example 2 Synthesis and Performance Evaluation of Strong Base Anion Exchange Resin with 4-Chlorobutanol as Spacer

[0033] Add 49.5 mL of 4-chlorobutanol, 800 mL of toluene, and 134 mL of 30% trimethylamine aqueous solution to a 1 L four-neck flask equipped with a stirrer, a condenser, and a thermometer, heat to 70°C for 24 hours, and distill the toluene Constantly replenish toluene to 110°C and keep it warm for 2 hours. Cool to room temperature, add the above-mentioned chlorine balls and 93 mL of 30% sodium methoxide solution, heat up to 65°C and react for 24 hours, distill off toluene, and wash to obtain strong base anion exchange resin B. Its volume exchange capacity C0=0.67 mmol / L, strong base content S0=100%.

[0034] Evaluation of High Temperature Resistance of Strong Base Anion Exchange Resin

[0035]Put a certain amount of resin to be tested into the reactor, add an appropriate amount of sodium hydroxide solution of appropriate concentration, stir, keep warm a...

Embodiment 3

[0046] Example 3 Synthesis and performance evaluation of strong base anion exchange resin with 6-chlorohexanol as spacer

[0047] Add 62.5 mL of 6-chlorohexanol, 800 mL of toluene, and 134 mL of 30% trimethylamine aqueous solution to a 1 L four-necked flask equipped with a stirrer, condenser and thermometer, heat to 70°C for 24 hours, and distill the toluene Constantly replenish toluene to 110°C and keep it warm for 2 hours. Cool to room temperature, add the above-mentioned chlorine spheres and 93 mL of 30% sodium methoxide solution, heat up to 65°C and react for 24 hours, distill off toluene, and wash to obtain strong base anion exchange resin C. Its volume exchange capacity C0=0.65 mmol / L, strong base content S0=100%.

[0048] Accurately measure V0 = 40.0 mL of the above resin, transfer it to an autoclave, add 80 mL of 0.1 N sodium hydroxide aqueous solution, seal the autoclave, and raise the temperature to 105 ° C for 168 hours. After cooling and washing, the resin volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com