Method for preparing copper-tungsten contact material by discharge plasmas

A discharge plasma and contact material technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high production cost and large energy consumption, achieve high production efficiency, low sintering temperature, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

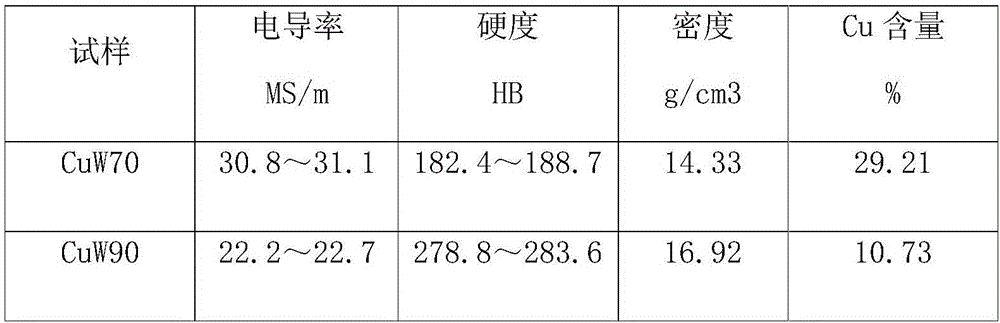

Examples

Embodiment 1

[0027] The method for preparing copper-tungsten contact material by spark plasma sintering comprises the following steps:

[0028] Step 1, sintering: Pour tungsten powder with a particle size of 4 μm into a graphite mold, place the mold in a hydrogen furnace, reduce the powder, lightly burn it, and put it in a plasma sintering furnace to vacuumize and pressurize. The above-mentioned plasma treatment is argon plasma treatment, and the treatment time is 15 minutes. When the pressure reaches 30MPa, a pulsed direct current of 1200A is introduced and the temperature is raised to 1320℃ at a heating rate of 100℃ / min. After holding for 2.5min, it is cooled with the furnace Get the tungsten skeleton;

[0029] Step 2, copper block treatment: take the copper block, firstly polish it mechanically, and then perform ultrasonic cleaning on the polished copper block in an ultrasonic cleaning solution with an ultrasonic frequency of 35KHz and a temperature of 30°C. Continuous or pulsed laser ...

Embodiment 2

[0034] Step 1, sintering: Pour tungsten powder with a particle size of 6 μm into a graphite mold, place the mold in a hydrogen furnace, reduce the powder, lightly burn it, and put it in a plasma sintering furnace to vacuumize and pressurize. The above plasma treatment is argon plasma treatment, and the treatment time is 17.5min. When the pressure reaches 37.5MPa, a pulsed direct current of 1500A is introduced and the temperature is raised to 1400℃ at a heating rate of 200℃ / min. Furnace cooling to obtain a tungsten skeleton;

[0035] Step 2, copper block treatment: take the copper block, firstly polish it mechanically, then perform ultrasonic cleaning on the polished copper block in an ultrasonic cleaning solution, the ultrasonic frequency is 42.5KHz, the temperature is 34°C, and after drying, the power is 12.5 watts Continuous or pulsed laser scanning at a speed of 255 mm / s for laser irradiation, cooling to room temperature, and then plasma treatment to obtain infiltrated copp...

Embodiment 3

[0040]Step 1, sintering: Pour tungsten powder with a particle size of 8 μm into a graphite mold, place the mold in a hydrogen furnace, reduce the powder, lightly burn it, and put it in a plasma sintering furnace to evacuate and pressurize. The above plasma treatment is argon plasma treatment, the treatment time is 20min, when the pressure reaches 45MPa, a pulsed direct current of 1800A is introduced and the temperature is raised to 1480°C at a heating rate of 300°C / min, and after holding for 5min, the furnace cools to obtain Tungsten skeleton;

[0041] Step 2, copper block treatment: take copper block, first use mechanical method to polish, the copper block after polishing is ultrasonically cleaned in ultrasonic cleaning solution, ultrasonic frequency is 50KHz, temperature is 38 ℃, after drying, use a power of 20 watts Continuous or pulsed laser scans at a speed of 500 mm / s, cools to room temperature, and then performs plasma treatment to obtain infiltrated copper blocks for u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com