A method for rapidly synthesizing tungsten sulfide nanopowder

A nano-powder and tungsten sulfide technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of long synthesis cycle, poor crystallinity, and low output, and achieve fast reaction speed, high conversion rate, and high output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

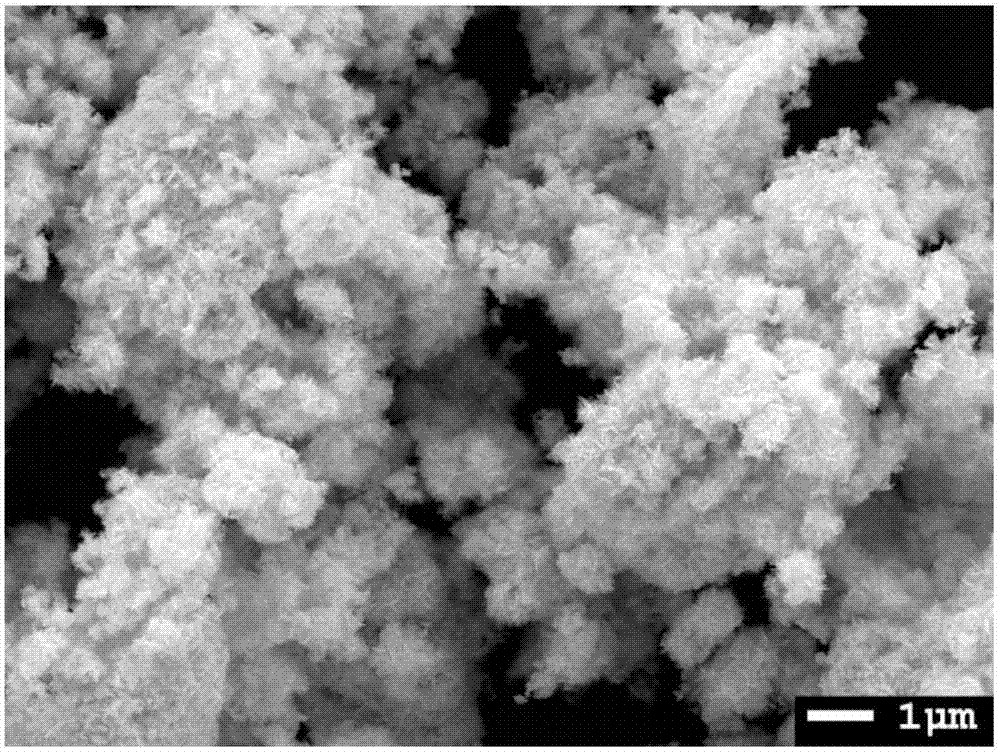

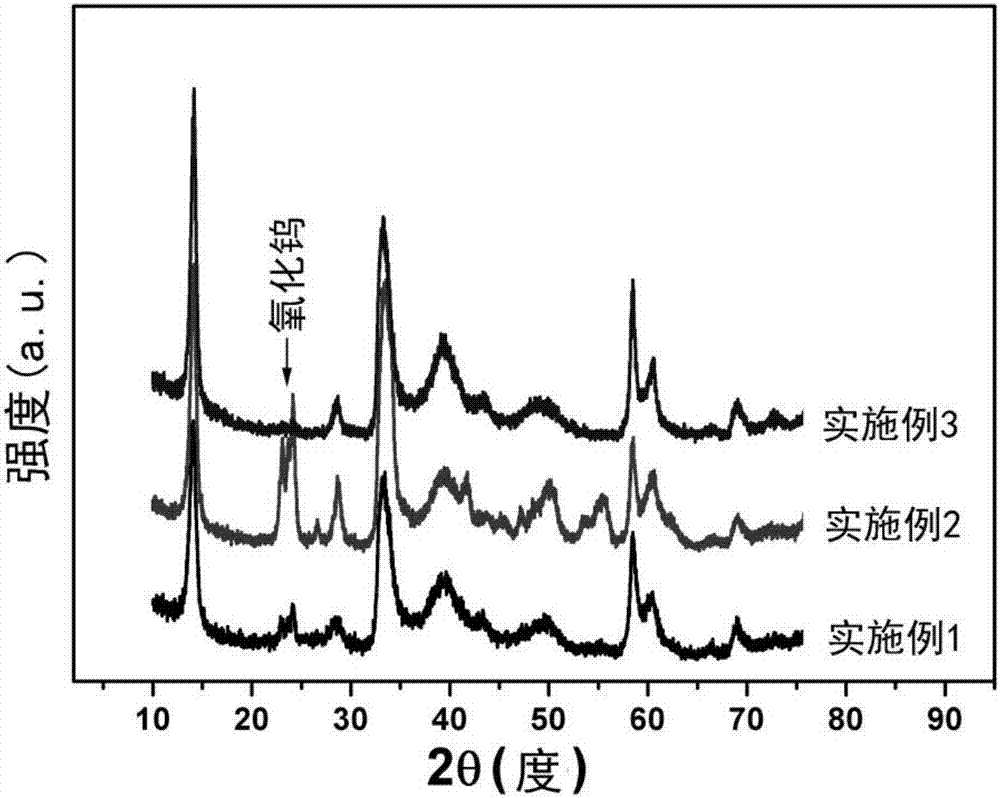

Embodiment 1

[0022] The method for rapidly synthesizing tungsten sulfide nanopowder of the present invention comprises the following steps:

[0023] Step 1, put 0.1g of tungstic acid powder in the quartz boat, and place it in the constant temperature zone of the openable tube furnace, put excess sulfur powder in the quartz boat, and place it in the tube furnace In the upstream area of the carrier gas, a separate heating jacket is added to control the temperature separately to ensure a constant evaporation rate of sulfur;

[0024] Step 2, first evacuate the quartz tube, and when the vacuum degree of the vacuum chamber is below 4Pa, pass the carrier gas argon (introduction speed 0.2L / min) and air (introduction speed 80mL / min) into the quartz tube , adjust the pressure in the quartz tube to be stable at 5KPa, start the heating program of the tube furnace and a separate heating mantle to control the velocity of sulfur evaporation, and increase the temperature of the constant temperature zone...

Embodiment 2

[0028] The method for rapidly synthesizing tungsten sulfide nanopowder of the present invention comprises the following steps:

[0029]Step 1, put 1g of tungstic acid powder in the quartz boat, and place it in the constant temperature zone of the openable tube furnace, put excess sulfur powder in the quartz boat, and place it in the tube furnace In the upstream area of the gas, a separate heating jacket is added to control the temperature separately to ensure a constant evaporation rate of sulfur;

[0030] Step 2, first evacuate the quartz tube, and when the vacuum degree of the vacuum chamber is below 4Pa, pass the carrier gas argon into the quartz tube (passing speed 0.2L / min), and adjust the pressure in the quartz tube to stabilize at 5KPa , start the heating program of the tube furnace and a separate external heating mantle to control the velocity of sulfur evaporation, raise the constant temperature zone of the tube furnace to 600 °C at a rate of 30 °C / min, and the cont...

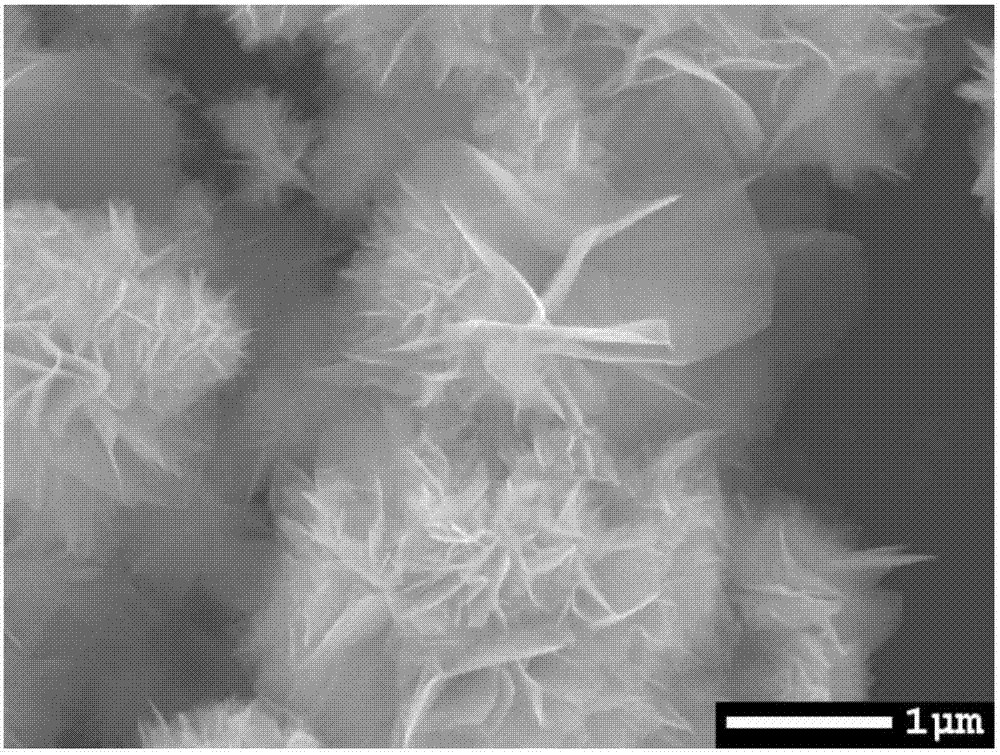

Embodiment 3

[0034] The method for rapidly synthesizing tungsten sulfide nanopowder of the present invention comprises the following steps:

[0035] Step 1, put 1g of tungstic acid powder in the quartz boat, and place it in the constant temperature zone of the openable tube furnace, put excess sulfur powder in the quartz boat, and place it in the tube furnace In the upstream area of the gas, a separate heating jacket is added to control the temperature separately to ensure a constant evaporation rate of sulfur;

[0036] Step 2, first evacuate the quartz tube, and when the vacuum degree of the vacuum chamber is below 4Pa, pass the carrier gas argon into the quartz tube (passing speed 0.2L / min), and adjust the pressure in the quartz tube to stabilize at 5KPa , start the heating program of the tube furnace and a separate external heating mantle to control the velocity of sulfur evaporation, raise the constant temperature zone of the tube furnace to 600 °C at a rate of 30 °C / min, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com