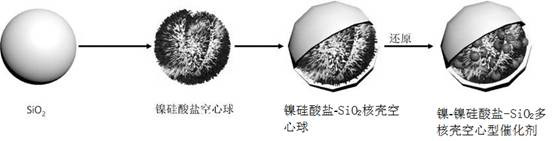

Methane reforming multi-core-shell hollow catalyst nickel-nickel silicate-sio 2 preparation method

A hollow, silicate technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as loss of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 200mL ethanol, 100mL water and 40mL orthosilicate methyl ester at 0o C and mix well. Add urea to adjust the pH to 10. After stirring for 2h, it was separated with a centrifuge. Wash with a mixture of methanol and water. Finally, 600nm silica nanoparticles were obtained at 150 o C dried for 24h.

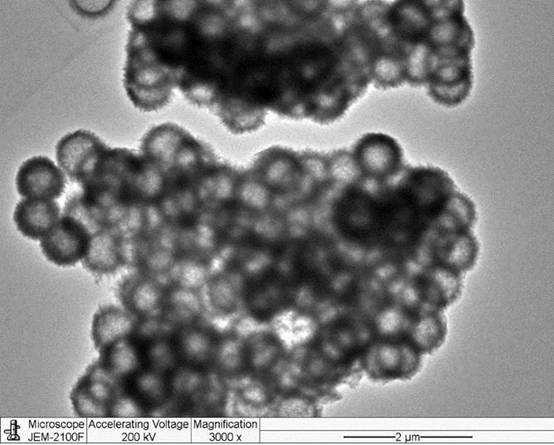

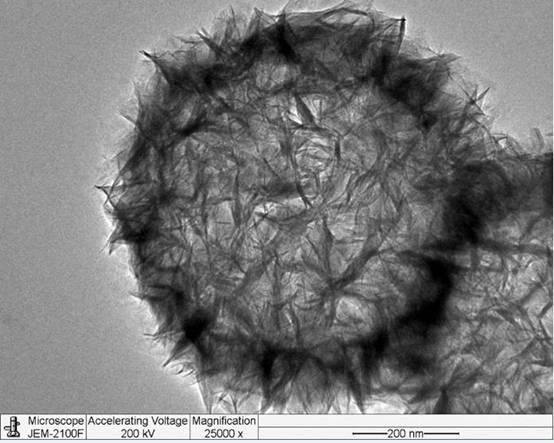

[0027] (2) Take 2g of silicon dioxide and 0.3g of nickel nitrate, add ammonia water, and adjust the pH to 8. Put the mixed solution into an autoclave, heat to 50°C, react for 24 hours, and cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain nickel silicate hollow spheres (such as figure 2 , shown in 3), the specific area is 250m 2 g -1 .

[0028] (3) Disperse hollow nickel silicate spheres in ethanol (30mL), water (10mL), C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added. The pH was adjusted to 10, and after stirring for 30 min, 10 ...

Embodiment 2

[0032] (1) 200mL ethanol, 100mL water and 40mL methyl orthosilicate at 35 o C and mix well. Add urea to adjust the pH to 10. After stirring for 2h, it was separated with a centrifuge. Wash with a mixture of methanol and water. Finally, 600nm silica nanoparticles were obtained at 150 o C dried for 24h.

[0033] (2) Take 2g of silicon dioxide and 0.3g of nickel nitrate, add ammonia water, and adjust the pH to 11. Put the mixed solution into an autoclave, heat to 50°C, react for 24 hours, and cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain nickel silicate hollow spheres (such as figure 2 , shown in 3), the specific area is 250m 2 g -1 .

[0034] (3) Disperse hollow nickel silicate spheres in ethanol (30mL), water (10mL), C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added. The pH was adjusted to 12, and after stirring for 30 min, 10 mL...

Embodiment 3

[0038] (1) 200mL ethanol, 100mL water and 40mL methyl orthosilicate at 70 o C and mix well. Add urea to adjust the pH to 10. After stirring for 2h, it was separated with a centrifuge. Wash with a mixture of methanol and water. Finally, 600nm silica nanoparticles were obtained at 150 o C dried for 24h.

[0039] (2) Take 2g of silicon dioxide and 0.3g of nickel nitrate, add ammonia water, and adjust the pH to 13. Put the mixed solution into an autoclave, heat to 50°C, react for 24 hours, and cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain nickel silicate hollow spheres (such as figure 2 , shown in 3), the specific area is 250m 2 g -1 .

[0040] (3) Disperse hollow nickel silicate spheres in ethanol (30mL), water (10mL), C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added. The pH was adjusted to 14, and after stirring for 30 min, 10 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com