Processing technology of wastewater produced during desalting water manufacturing in viscose fiber production

A viscose fiber and treatment process technology, applied in the field of waste water treatment process, can solve the problems of inability to treat waste water well, and achieve the effect of low cost, low cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

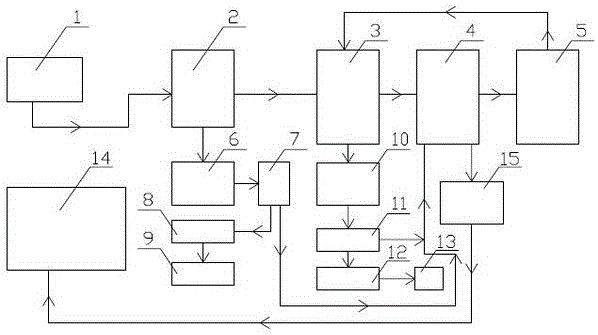

Image

Examples

Embodiment 1

[0038] A kind of treatment process that produces the waste water that produces desalted water in producing viscose fiber, comprises the following process steps:

[0039] A, recovery of magnesium hydroxide

[0040] Wastewater from the reverse osmosis membrane equipment used to produce desalinated water is discharged into the magnesium hydroxide sedimentation tank, and sodium hydroxide is added to the magnesium hydroxide sedimentation tank to obtain a magnesium hydroxide emulsion, which is separated, washed and separated again , obtain magnesium hydroxide solid product;

[0041] B. Recovery of calcium sulfate

[0042] The mother liquor containing calcium chloride and sodium chloride in the magnesium hydroxide precipitation tank enters the calcium sulfate precipitation tank after filtration, and the sodium sulfate solution in the sodium sulfate dissolution tank enters the calcium sulfate precipitation tank, is stirred and mixed, and then separated, washed and Separate again to ...

Embodiment 2

[0056] A kind of treatment process that produces the waste water that produces desalted water in producing viscose fiber, comprises the following process steps:

[0057] A, recovery of magnesium hydroxide

[0058] Wastewater from the reverse osmosis membrane equipment used to produce desalinated water is discharged into the magnesium hydroxide sedimentation tank, and sodium hydroxide is added to the magnesium hydroxide sedimentation tank to obtain a magnesium hydroxide emulsion, which is separated, washed and separated again , obtain magnesium hydroxide solid product;

[0059] B. Recovery of calcium sulfate

[0060] The mother liquor containing calcium chloride and sodium chloride in the magnesium hydroxide precipitation tank enters the calcium sulfate precipitation tank after filtration, and the sodium sulfate solution in the sodium sulfate dissolution tank enters the calcium sulfate precipitation tank, is stirred and mixed, and then separated, washed and Separate again to ...

Embodiment 3

[0070] A kind of treatment process that produces the waste water that produces desalted water in producing viscose fiber, comprises the following process steps:

[0071] A, recovery of magnesium hydroxide

[0072] Wastewater from the reverse osmosis membrane equipment used to produce desalinated water is discharged into the magnesium hydroxide sedimentation tank, and sodium hydroxide is added to the magnesium hydroxide sedimentation tank to obtain a magnesium hydroxide emulsion, which is separated, washed and separated again , obtain magnesium hydroxide solid product;

[0073] B. Recovery of calcium sulfate

[0074] The mother liquor containing calcium chloride and sodium chloride in the magnesium hydroxide precipitation tank enters the calcium sulfate precipitation tank after filtration, and the sodium sulfate solution in the sodium sulfate dissolution tank enters the calcium sulfate precipitation tank, is stirred and mixed, and then separated, washed and Separate again to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com