Energy-efficient continuous sludge resource processing system

A treatment system, energy-saving technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Energy waste, equipment power, large size and other problems, to achieve the effect of reducing power, improving equipment efficiency, and reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

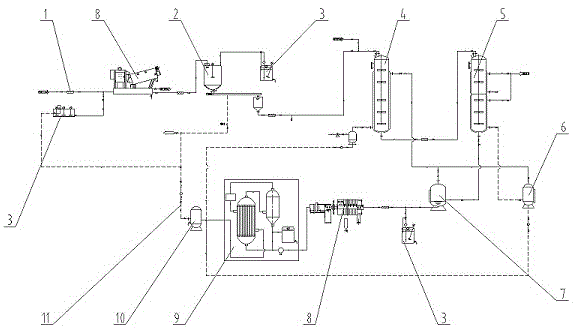

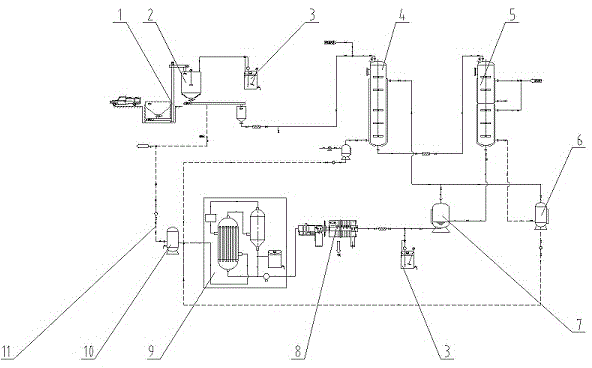

[0032] Example 1: In-situ treatment of sewage treatment plant sludge

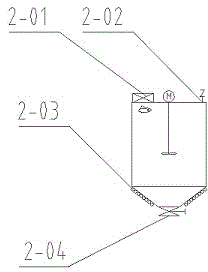

[0033] An energy-saving continuous sludge resource treatment system consists of a sludge conveying device 1, a sludge storage tank 2, a dosing device 3, a preheating mixer 4, a plug flow reactor 5, a condensate flash device 6, and a material It consists of a flash evaporation device 7, a sludge dehydration device 8, a protein liquid separation device 9, a water storage tank 10, and a water delivery device 11.

[0034]The outlet of the sludge conveying device 1 is connected to the material inlet of the sludge storage tank 2, the outlet of the dosing device 3 is connected to the dosing port 2-02 of the sludge storage tank 2, and the outlet of the sludge storage tank 2 is equipped with sludge conveying Device 1, the outlet of the sludge conveying device 1 is connected to the material inlet of the preheating agitator 4, the material outlet of the preheating agitator 4 is provided with a sludge conveying device ...

Embodiment 2

[0036] Example 2: Treatment of imported sludge

[0037] An energy-saving continuous sludge resource treatment system consists of a sludge conveying device 1, a sludge storage tank 2, a dosing device 3, a preheating mixer 4, a plug flow reactor 5, a condensate flash device 6, and a material It consists of a flash evaporation device 7, a sludge dehydration device 8, a protein liquid separation device 9, a water storage tank 10, and a water delivery device 11.

[0038] The outlet of the sludge conveying device 1 is connected to the material inlet of the sludge storage tank 2, the outlet of the dosing device 3 is connected to the dosing port 2-02 of the sludge storage tank 2, and the outlet of the sludge storage tank 2 is equipped with sludge conveying Device 1, the outlet of the sludge conveying device 1 is connected to the material inlet of the preheating agitator 4, the material outlet of the preheating agitator 4 is provided with a sludge conveying device 1, and the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com