Purifying agent for aquaculture and preparation method of purifying agent

A technology of aquaculture and purification agent, which is applied in the direction of chemical instruments and methods, water pollutants, animal husbandry wastewater treatment, etc., and can solve problems such as low culture and professional quality of breeding personnel, drug resistance of pathogenic microorganisms, loss of therapeutic effect, etc. Achieve the effects of improving quality and safety, improving water quality, and being suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

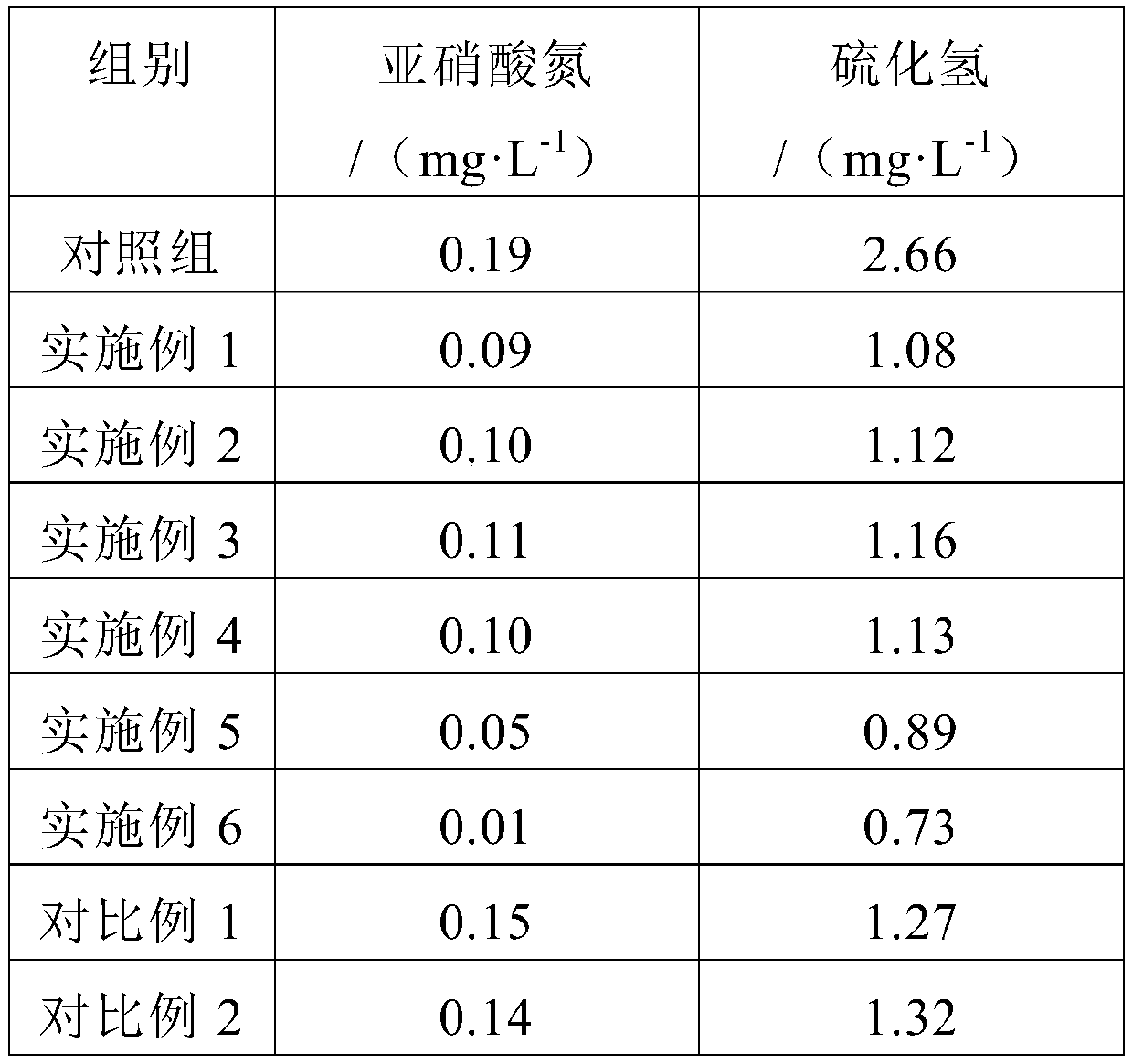

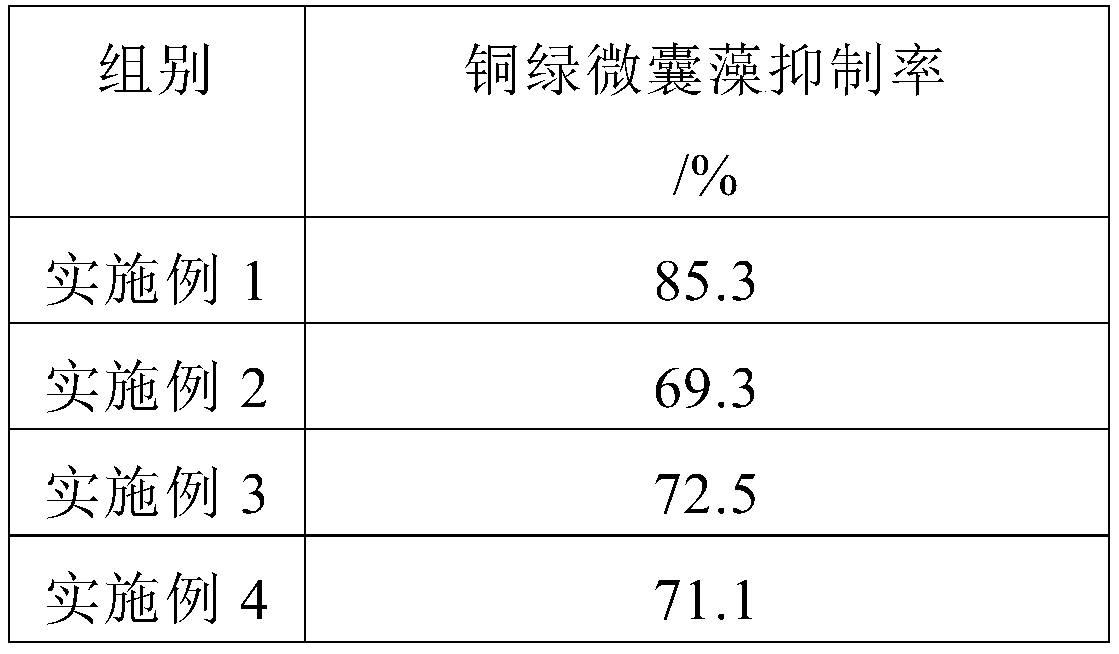

Examples

preparation example Construction

[0054] The preparation method of the extract of the scallop leaf is as follows: take the scallop and place it at 50° C. to dry for 4 hours, crush it to 100 meshes to obtain the scallop powder, add 50 wt % ethanol aqueous solution which is 4 times the mass of the scallop powder, perform supercritical extraction for 3 hours, extract The pressure is 20MPa, the extraction temperature is 40°C, the separation pressure is 5MPa, and the separation temperature is 35°C to obtain a supercritical extract and a supercritical raffinate; add 50 wt% of 20 times the mass of the supercritical raffinate to the above supercritical raffinate The methanol aqueous solution was placed at 55°C for ultrasonic treatment for 20 minutes, the ultrasonic power of the ultrasonic treatment was 350W, and the ultrasonic frequency was 30kHz to obtain an ultrasonic extract; the above-mentioned supercritical extract and ultrasonic extract were combined, filtered through a 250-mesh filter cloth, The obtained filtrat...

Embodiment 1

[0063] The purification agent for aquaculture is prepared from the following raw materials in parts by mass: 35 parts of activated carbon, 15 parts of compound enzyme agent, 52 parts of curing agent, 1.6 parts of scallop leaf extract, 1.6 parts of watercress leaf extract, phoenix lotus 1.6 parts of root extract, 15 parts of polyaluminum chloride, 5 parts of sodium alginate, 3 parts of sodium dodecylbenzenesulfonate.

[0064] The compound enzyme agent is formed by mixing protease, lipase and laccase in a mass ratio of 2:1:1.

[0065] The curing agent is prepared by mixing montmorillonite, modified bentonite and chitosan modified diatomite in a mass ratio of 1:1:1.

[0066] The preparation method of described gac is:

[0067] Ⅰ. Dry the coconut shell at 50°C for 7 hours, crush it to 400 mesh, and obtain the pretreated raw material powder;

[0068] Ⅱ. The above-mentioned pretreated raw material powder is activated by heating up to 700°C at a rate of 15°C / min under the protectio...

Embodiment 2

[0087] It is basically the same as Example 1, the only difference is that the purifying agent for aquaculture is prepared from the following parts by mass of raw materials: 35 parts of activated carbon, 15 parts of composite enzyme agent, 52 parts of curing agent, and 2.4 parts of scallop leaf extract , 2.4 parts of watercress leaf extract, 15 parts of polyaluminium chloride, 5 parts of sodium alginate, 3 parts of sodium dodecylbenzenesulfonate.

[0088] The preparation method of the clarifier for aquaculture comprises the following steps:

[0089] Ⅰ. Weigh each raw material component by mass parts;

[0090] Ⅱ. Add water with 12 times the mass of the compound enzyme to the compound enzyme, stir at 30°C and 200r / min for 20min to obtain a mixed enzyme liquid, then add activated carbon to the mixed enzyme liquid, and stir at 30°C and 200r / min / min under the condition of constant temperature adsorption for 65min, that is, a mixed solution containing enzyme-loaded activated carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com