Method for preparing glass ceramic material with high-calcium sulfur-fixing flyash

A technology of glass ceramics and fly ash, which is applied in the field of disposal and reuse of high-calcium sulfur-fixed fly ash, can solve the problems of low utilization rate of fly ash and low proportion of fly ash added, and achieve reduction of preparation cost, The effect of reducing the amount of addition and increasing the utilization ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The glass-ceramic material was prepared by using the sulfur-fixed fly ash of the 150MW circulating fluidized bed unit of Guizhou Huadian Bijie Thermal Power Co., Ltd. as the raw material. The chemical composition of the raw material is shown in Table 1. The specific operation steps are as follows:

[0024] Table 1 Composition of sulfur-fixed fly ash of Guizhou Huadian Bijie Thermal Power Co., Ltd. 150MW circulating fluidized bed unit

[0025] Element

SiO 2

Al 2 o 3

CaO

SO 3

MgO

TiO 2

Fe 2 o 3

Na 2 o

K 2 o

content(%)

21.8

16.9

35.5

14.3

1.04

1.43

7.3

0.74

0.69

[0026] (1) According to Al 2 o 3 2 2 The powder is ground and mixed evenly, and the percentages are all percentages by mass.

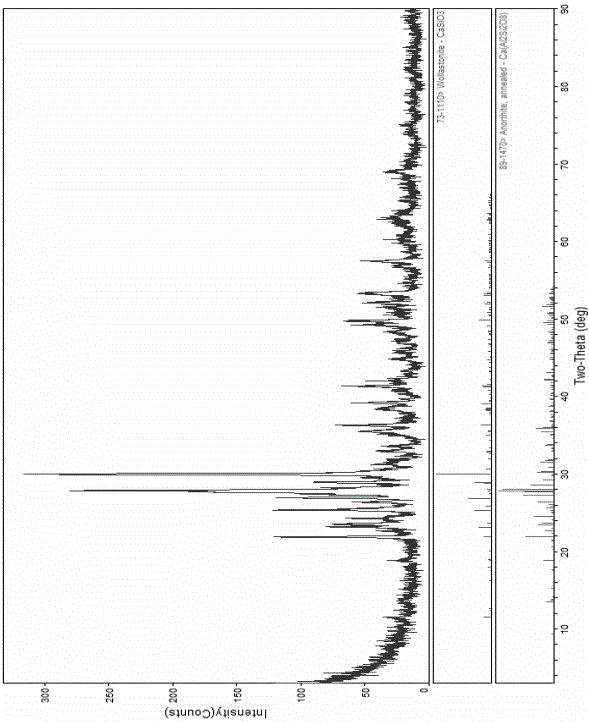

[0027] (2) Carry out melting treatment at a temperature of 1400°C, keep warm for 0.5h for clarification, and then quickly pour the basic glass solution into water for quenching to obtai...

Embodiment 2

[0032] The glass-ceramic material is prepared from the sulfur-fixed bottom ash raw material of the 300MW circulating fluidized bed unit of Yunnan Huadian Inspection Division Power Generation Co., Ltd. The chemical composition of the raw material is shown in Table 2, and the specific operation steps are as follows:

[0033] Table 2 Composition of sulfur-fixed bottom ash of 300MW circulating fluidized bed unit of Yunnan Huadian Inspection Division Power Generation Co., Ltd.

[0034] Element

SiO 2

Al 2 o 3

CaO

SO 3

MgO

TiO 2

Fe 2 o 3

Na 2 o

K 2 o

content(%)

10.7

7.9

56.7

17.3

1.93

0.73

3.66

—

0.79

[0035] (1) According to Al 2 o 3 2 2 The powder is ground and mixed evenly, and the percentages are all percentages by mass.

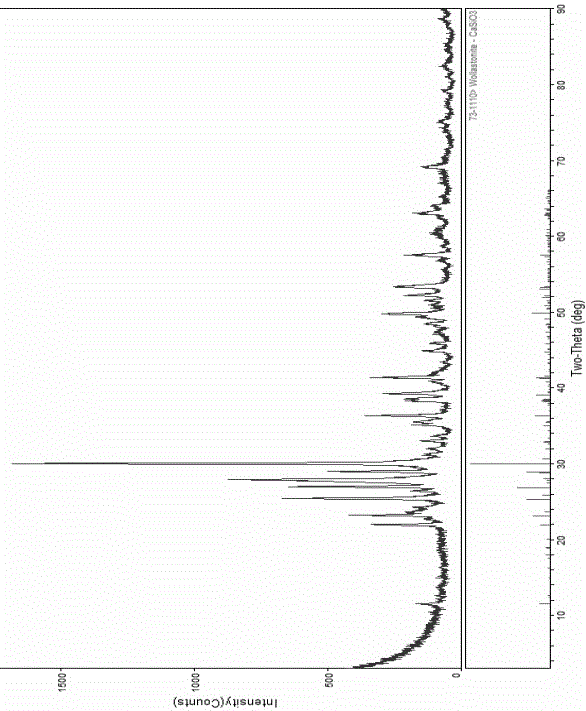

[0036] (2) Carry out melting treatment at a temperature of 1400°C, keep warm for 0.5h for clarification, and then quickly pour the basic glass solution into...

Embodiment 3

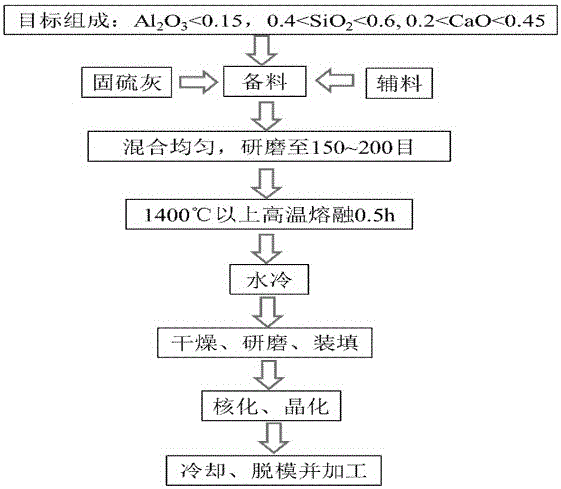

[0041] see figure 1 In this example, the steps of the method for preparing glass-ceramic materials with high-calcium-sulfur-fixing fly ash are as follows.

[0042] (1) Composition adjustment: use high-calcium sulfur-fixing fly ash as the main material, and add SiO to the main material 2 Auxiliary material and / or CaO auxiliary material and mix homogeneously to obtain mixed material; In described mixed material, Al 2 o 3 2 2 The auxiliary material can be quartz sand, quartz tailing sand or waste glass, and the CaO auxiliary material can be limestone or quicklime.

[0043] (2) Electric melting: put the mixture into a resistance melting furnace to melt into a glass solution, the temperature in the resistance melting furnace is higher than 1400°C, and the melting time is 30 minutes.

[0044] (3) Water-cooling and quenching the glass solution to obtain granular molten slag.

[0045] (4) Dry, pulverize and grind the granular slag to a particle size of less than 0.5 mm, and then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com