Preparation method for saccharose zinc complex

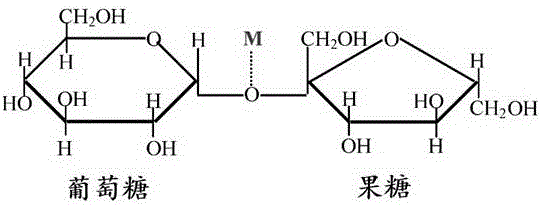

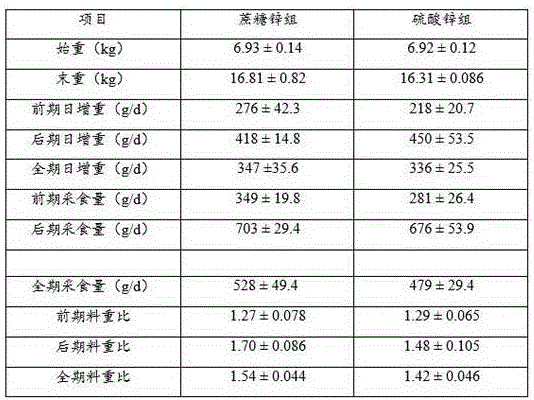

A technology of complex and sucrose, applied in the field of complex, can solve the problem of high cost of use, achieve the effects of improving production efficiency, good palatability, and realizing repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of sucrose zinc complex comprises the steps:

[0038] Step 1. Add 25 parts by weight of sucrose to the reaction kettle, add 40 parts by weight of water to dissolve the sucrose, add aqueous sodium hydroxide solution to alkalinize, and adjust the pH of the solution to 11;

[0039] Step 2, heating the reaction kettle, keeping the temperature in the kettle at 65° C., and then adding 85 parts by weight of zinc sulfate heptahydrate for complexation reaction for 1 hour, stirring continuously during the reaction to generate zinc sucrose solution, cooling, filtering and separating to obtain filter residue and filtrate;

[0040] Step 3: According to the weight ratio of filtrate: 75% ethanol aqueous solution = 1:2, add 75% ethanol aqueous solution to precipitate at room temperature, the precipitation time is 1.5 hours, the precipitate is centrifugally filtered, and the obtained waste water is recycled, and the precipitate is vacuum-dried , detect and obtain ...

Embodiment 2

[0044] The preparation method of sucrose zinc complex comprises the steps:

[0045] Step 1. Add 28 parts by weight of sucrose to the reaction kettle, add 45 parts by weight of water to dissolve the sucrose, add aqueous sodium hydroxide solution to alkalinize, and adjust the pH of the solution to 11;

[0046] Step 2, heating the reaction kettle, keeping the temperature in the kettle at 70°C, and then adding 95 parts by weight of zinc sulfate heptahydrate to carry out the complexation reaction for 1.5 hours, stirring continuously during the reaction process, generating a zinc sucrose solution, cooling, filtering and separating, and obtaining filter residue and filtrate;

[0047] Step 3: According to the weight ratio of filtrate: 75% ethanol aqueous solution = 1:2, add 75% ethanol aqueous solution to carry out normal temperature precipitation, the precipitation time is 2 hours, the precipitate is subjected to centrifugal suction filtration, and the waste water obtained is recycled...

Embodiment 3

[0051] The preparation method of sucrose zinc complex comprises the steps:

[0052] Step 1. Add 32 parts by weight of sucrose to the reaction kettle, add 50 parts by weight of water to dissolve the sucrose, and then alkalize the solution by adding aqueous sodium hydroxide solution to adjust the pH of the solution to 12;

[0053] Step 2, heating the reaction kettle, keeping the temperature in the kettle at 75° C., then adding 100 parts by weight of zinc sulfate heptahydrate for complexation reaction for 2 hours, stirring continuously during the reaction process, generating a zinc sucrose solution, cooling, filtering and separating to obtain filter residue and filtrate;

[0054] Step 3: According to the weight ratio of filtrate:75% ethanol aqueous solution=1:2, add 75% ethanol aqueous solution to carry out normal temperature precipitation, the precipitation time is 3 hours, the precipitate is subjected to centrifugal suction filtration, and the waste water obtained is recycled, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com