Long chain branch polyphenyl ether anionic membrane and preparation method thereof

An anion membrane, polyphenylene ether technology, applied in the field of long-chain branched polyphenylene ether anion exchange membrane and its preparation, can solve the problem that the benzylic quaternary ammonium group is unstable, prone to degradation, and cannot meet the long-term use of alkaline fuel cells. Requirements and other issues, to achieve the effect of improving OH-conductivity, good mobility, and improving alkali resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

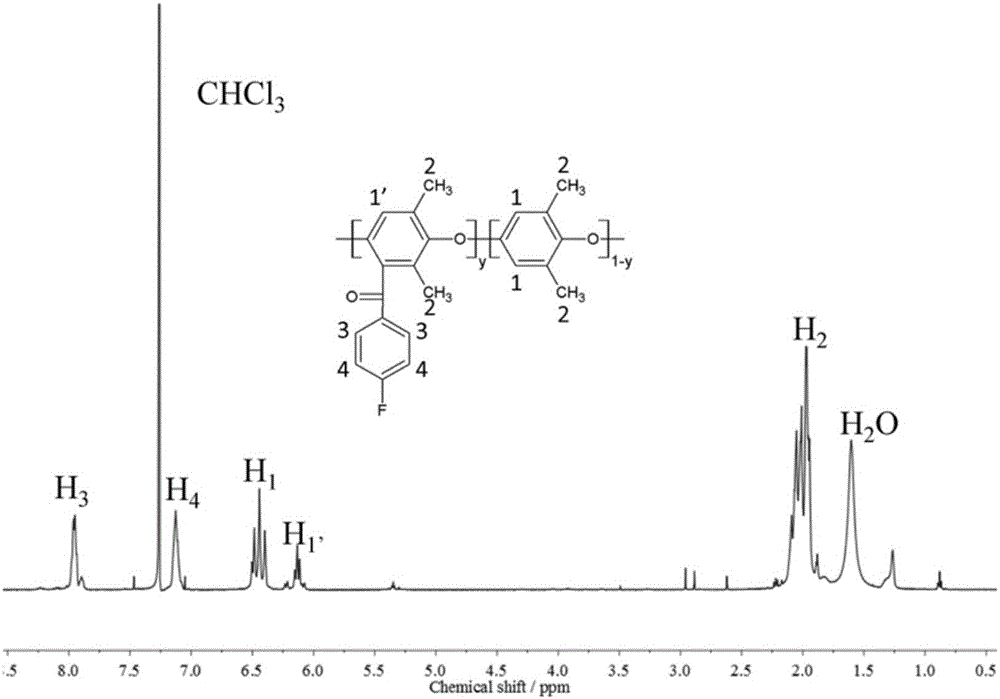

[0046] Preparation of acylated polyphenylene ether: under nitrogen protection, dissolve 2.4g polyphenylene ether in 70mL dichloroethane, add 1.61g aluminum trichloride, add 1.3mL p-fluorobenzoyl chloride drop by drop, at 60°C After reacting for 6 hours, add excess methanol, filter, wash with methanol, dry and reprecipitate with chloroform, and vacuum dry at 60°C to obtain acylated polyphenylene ether.

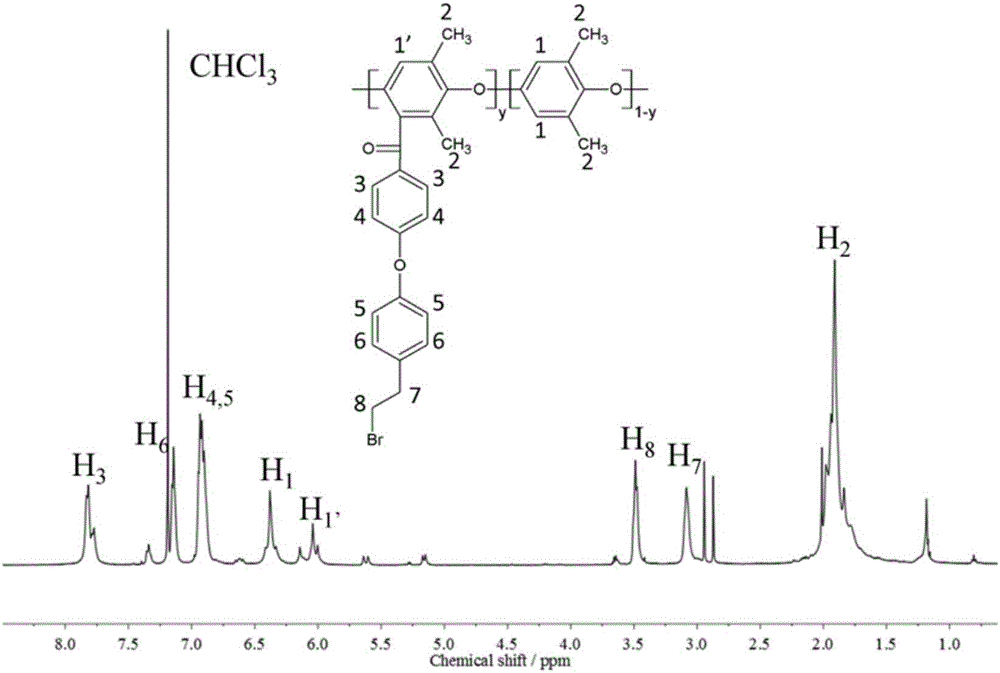

[0047] Condensation reaction: under nitrogen protection, dissolve 2 g of the acylated polyphenylene ether obtained above in 30 mL of N,N-dimethylacetamide, add 1.5 times the molar amount of p-hydroxyphenethyl alcohol, and 2.5 times the molar amount of anhydrous potassium carbonate, Then add 15mL of toluene, after azeotropic dehydration at 135°C for 4h, evaporate the dehydrating agent, then react at 150°C for 5h, add excess ethanol, wash, and dry to obtain a long-chain hydroxyl-containing polymer.

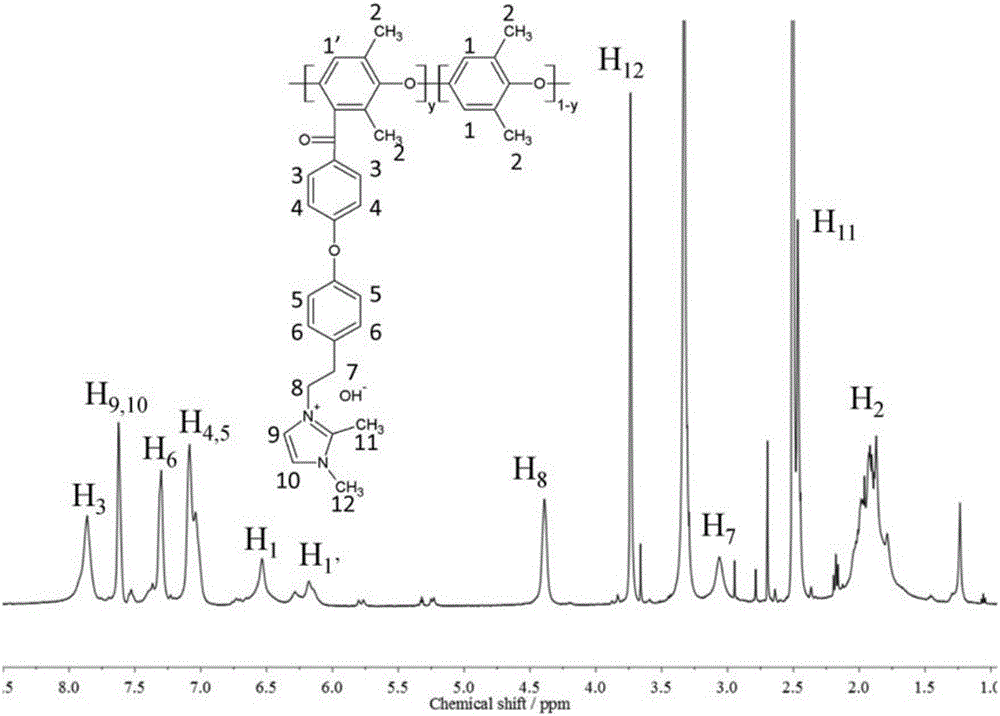

[0048] Hydroxyl bromide: Under nitrogen protection, dissolve 0.3g of a polymer c...

Embodiment 2

[0055] Preparation of acylated polyphenylene ether: under nitrogen protection, dissolve 2.4g polyphenylene ether in 70mL dichloroethane, add 1.90g aluminum trichloride, add 1.43mL p-fluorobenzoyl chloride drop by drop, at 60°C After reacting for 6 hours, add excess methanol, filter, wash with methanol, dry and reprecipitate with chloroform, and vacuum dry at 60°C to obtain acylated polyphenylene ether.

[0056] Condensation reaction: with embodiment 1

[0057] Hydroxyl bromide: with embodiment 1

[0058] Preparation of long-chain branched polyphenylene ether anion exchange membrane: same as Example 1

[0059] Tests show that the water content of the long-chain branched polyphenylene ether anion exchange membrane prepared in this example is 37%, and the ion conductivity is 18mS cm -1 , its anion exchange capacity is 1.51mmol.g -1 , the tensile strength is 16.7 MPa, which shows that the homogeneous anion exchange membrane prepared in this example has less swelling, has suitab...

Embodiment 3

[0061] Preparation of acylated polyphenylene ether: Under the protection of nitrogen, dissolve 2.4g polyphenylene ether in 70mL dichloroethane, add 2.88g aluminum trichloride, add 2.2mL p-fluorobenzoyl chloride dropwise, at 60°C After reacting for 6 hours, add excess methanol, filter, wash with methanol, dry and reprecipitate with chloroform, and vacuum dry at 60°C to obtain acylated polyphenylene ether.

[0062] Condensation reaction: with embodiment 1

[0063] Hydroxyl bromide: with embodiment 1

[0064] Preparation of long-chain branched polyphenylene ether anion exchange membrane: same as Example 1

[0065] Tests have shown that the water content of the long-chain branched polyphenylene ether anion exchange membrane prepared in this example is 50%, and the ion conductivity is 32mS cm -1 , its anion exchange capacity is 1.69mmol.g -1 , the tensile strength is 15.8 MPa, which shows that the homogeneous anion exchange membrane prepared in this example has less swelling, ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com