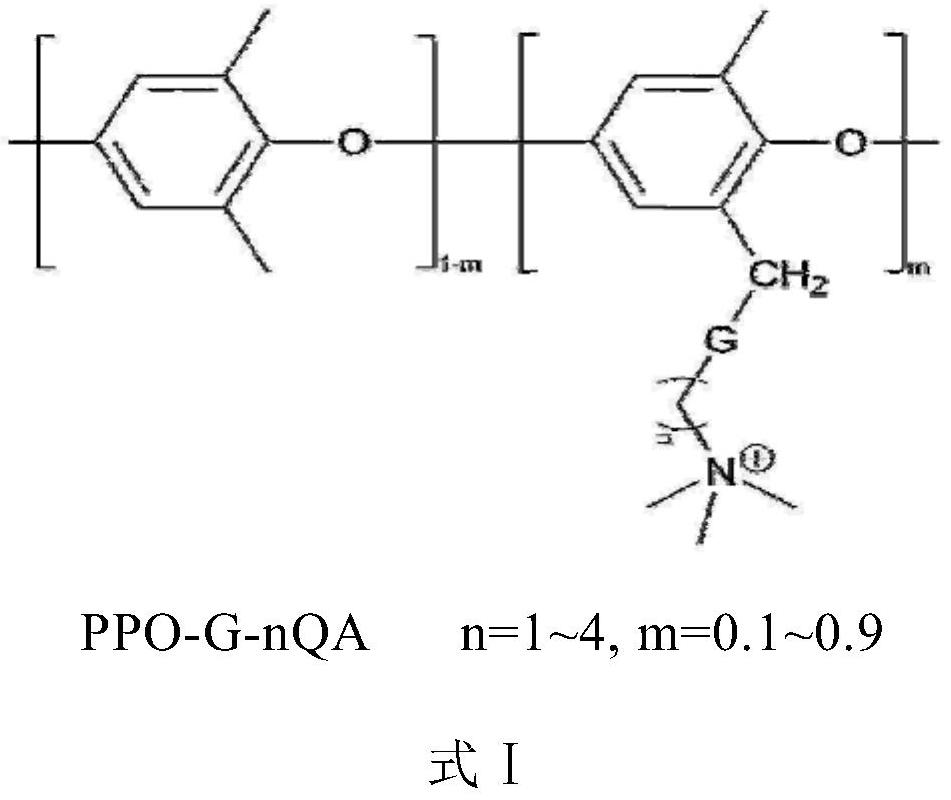

Triazolyl long side chain-containing polyphenyl ether anion membrane as well as preparation method and application thereof

An anionic membrane and a technology with a long triazole group, which is applied in the field of polyphenylene ether anionic membrane and its preparation, can solve the problems of decreased ionic conductivity and the inability to meet the large-scale industrialization of alkaline fuel cells, etc., and achieve improved alkali resistance stability, The effect of improving hydroxide conductivity and good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

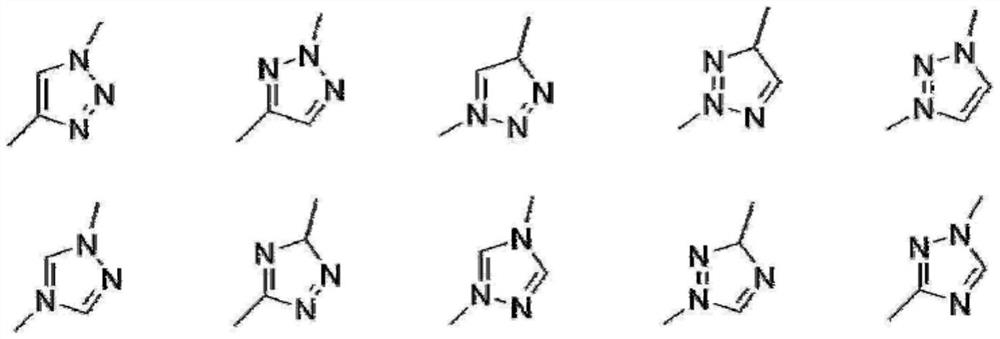

Method used

Image

Examples

Embodiment 1

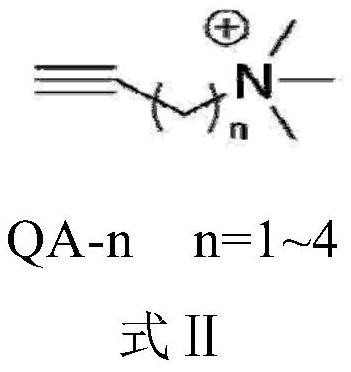

[0046] (1) Alkynyl functionalization of quaternary ammonium salts: Propynyl bromide (30 mmol), trimethylamine (150 mmol in 20 mL of tetrahydrofuran solution) and 100 mL of toluene were added to a 250 mL round bottom flask. After stirring at room temperature for 24 h, the white precipitate was filtered, washed three times with ether, and dried in vacuo to obtain alkynyl-functionalized quaternary ammonium salt QA-1 with a yield of 82%.

[0047] (2) Cu(I)-catalyzed azide-alkynyl cycloaddition (CuAAC) reaction: PPO-N3-m copolymer, m is 30% (1.814mmol azide group), QA-1 (2.177 mmol), catalyst pentamethyldiethylenetriamine (PMDETA) (0.227 mL, 1.089 mmol), CuBr (0.544 mmol) and 10 mL of NMP were added to a Shrek flask. Degassed by several freeze-thaw pump cycles, filling the bottle with argon and stirring at 50°C for 48h. The polymer solution was poured into deionized water, and the solid product (PPO-G-QA) was washed several times with water to remove the catalyst, and then vacuum-...

Embodiment 2

[0051] (1) Alkynyl functionalization of quaternary ammonium salts: 4-bromo-1-butyne (30 mmol), trimethylamine (150 mmol in 20 mL of tetrahydrofuran solution) and 100 mL of toluene were added to a 250 mL round bottom flask. After stirring at room temperature for 24 h, the white precipitate was filtered, washed with ether three times, and dried in vacuo to obtain alkynyl-functionalized quaternary ammonium salt QA-2 with a yield of 82%.

[0052] (2) Cu(I) catalyzed azide-alkynyl cycloaddition (CuAAC) reaction: with embodiment 1, just replace QA-1 in embodiment 1 step (2) with QA-2, obtain solid product (PPO-G-2QA).

[0053] (3) Membrane preparation and ion exchange: the same as in Example 1, except that the raw material PPO-G-QA in step (3) of Example 1 was replaced with PPO-G-2QA.

[0054] The test shows that the water content of the long-chain branched polyphenylene ether anion exchange membrane prepared in this example is 38%, and the ionic conductivity is 19mS·cm -1 , its a...

Embodiment 3

[0056] (1) Alkynyl functionalization of quaternary ammonium salts: 5-iodo-1-pentyne (30 mmol), trimethylamine (150 mmol in 20 mL of tetrahydrofuran solution) and 100 mL of toluene were added to a 250 mL round bottom flask. After stirring at room temperature for 24 h, the white precipitate was filtered, washed with ether three times, and dried in vacuo to obtain alkynyl-functionalized quaternary ammonium salt QA-3 with a yield of 82%.

[0057] (2) Cu(I) catalyzed azide-alkynyl cycloaddition (CuAAC) reaction: with embodiment 1, just replace QA-1 in embodiment 1 step (2) with QA-3, obtain solid product (PPO-G-3QA).

[0058] (3) Membrane preparation and ion exchange: the same as in Example 1, except that the raw material PPO-G-QA in step (3) of Example 1 was replaced with PPO-G-3QA.

[0059] The test shows that the water content of the long-chain branched polyphenylene ether anion exchange membrane prepared in this example is 44%, and the ionic conductivity is 24mS·cm -1 , its a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com