Light-weight automobile pillar protecting plate and preparing method thereof

An automotive pillar guard, lightweight technology, applied in vehicle parts, other household appliances, household appliances, etc., can solve the problems of decreased tensile strength, reduced performance strength of parts, etc., and achieves low production cost, low VOC content, Easy to achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

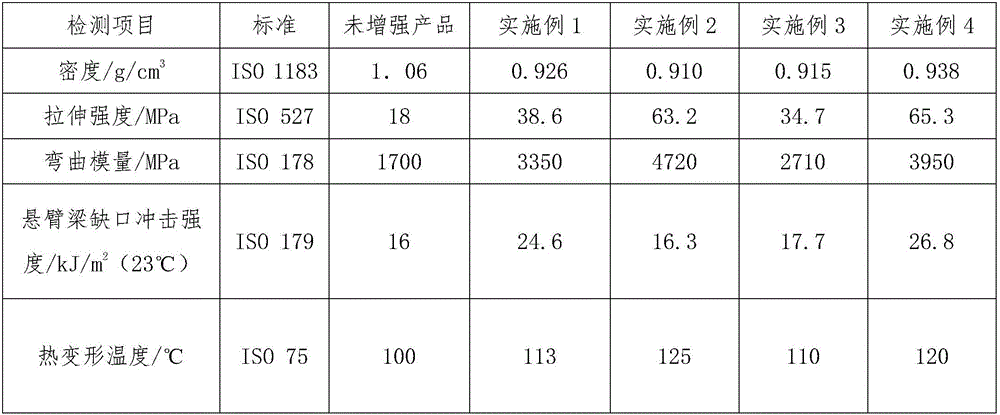

Embodiment 1

[0042] Mix 3 parts of polyethylene glycol, whiskers and sodium bicarbonate in a weight ratio of 6:1:3 to form a mixture, add this mixture to a twin-screw extruder, and prepare a functional masterbatch by extrusion; 60 parts of polypropylene with a melt index of 20g / 10min and a crystallinity of 75%, 10 parts of branched polypropylene with a melt strength of 26cN and a melt index of 5g / 10min, 0.5 part of sorbitol, 0.5 part of erucamide, resistance 0.6 parts of oxygen agent 1010, 0.4 parts of antioxidant 168, and 5 parts of silicone are put into a high-speed mixer and mixed for 3 minutes to obtain a mixture; the mixture obtained above is added through the main feed hopper of the twin-screw extruder, and talcum powder 20 parts are added to the barrel through side feeding, plasticized, extruded, stretched, air-dried, and pelletized to obtain the main composite material suitable for lightweight automobile pillar guards.

[0043] The composite material obtained in the above steps and th...

Embodiment 2

[0046] Mix 8 parts of ethylene-vinyl acetate copolymer, carbon nanotubes, and azodicarbonamide in a weight ratio of 7:1:2 to form a mixture, add this mixture to a twin-screw extruder, and successfully prepare by extrusion Energy masterbatch; 74.5 parts of polypropylene with a melt index of 5g / 10min and a crystallinity of 80%, 5 parts of branched polypropylene with a melt strength of 22cN and a melt index of 3g / 10min, 0.2 parts of sodium benzoate, polyethylene 1 part of wax, 0.1 part of antioxidant N,N'-dibenzylhydroxylamine, 0.2 part of antioxidant 168, and 1 part of polytetrafluoroethylene are put into a high-speed mixer and mixed for 6 minutes to obtain a mixture; combine the above-obtained mixture It is added through the main feeding hopper of the twin-screw extruder, and 10 parts of calcium carbonate is added to the barrel through side feeding, and plasticized, extruded, stretched, air-dried, and pelletized to obtain a column guard suitable for lightweight automobiles. The ...

Embodiment 3

[0050] Mix 2 parts of polyethylene, nano-Montorite, and azobisisobutyronitrile in a weight ratio of 6:2:2 to form a mixture, add this mixture to a twin-screw extruder, and prepare a functional masterbatch by extrusion ; Polypropylene with a melt index of 15g / 10min and a crystallinity of 77%, 79 parts, a branched polypropylene with a melt strength of 25cN and a melt index of 4g / 10min, 6 parts, aromatic heterocyclic organophosphate 0.3 parts, B 0.7 parts of bis-stearamide, 0.3 parts of antioxidants 1010, 0.2 parts of antioxidants 168, and 1.5 parts of polytetrafluoroethylene were put into a high-speed mixer and mixed for 4 minutes to obtain a mixture; the mixture obtained above was extruded through a twin screw The main feeding hopper of the machine is added, and 10 parts of kaolin are added to the barrel through side feeding, and plasticized, extruded, stretched, air-dried, and pelletized to obtain the main composite material suitable for lightweight automobile column guards. . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com