High-hardness mouldproof wallpaper base membrane and preparation technology thereof

A wallpaper base film and preparation technology, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of unsatisfactory anti-mildew effect, high biohazard, and wallpaper base film cannot meet the daily requirements. Requirements and other issues, to achieve good anti-mildew effect, good film-forming properties, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

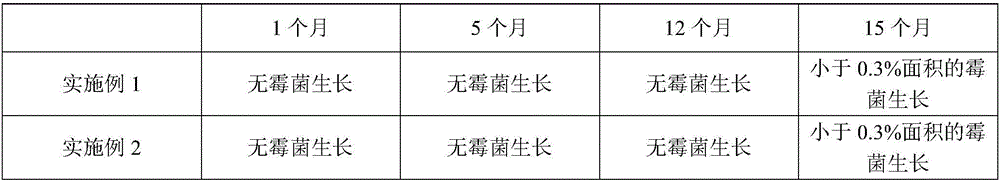

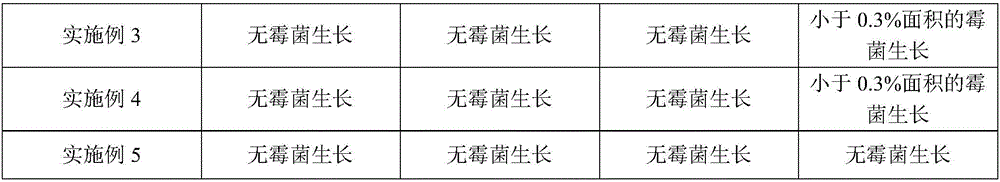

Examples

Embodiment 1

[0024] A high-hardness mildew-resistant wallpaper base film is made of the following components: 35kg of polyvinyl alcohol (1700 degree of polymerization, 74800 relative molecular mass), 20kg of silicone acrylic emulsion, 15kg of glycidyl methacrylate, 16kg of isocyanate, 15kg of monophenyldiisooctyl phosphite, 5kg of sodium stearate, 5kg of gum arabic, 6kg of gelatin, 5kg of glycerin, 3kg of sodium hexametaphosphate, 2kg of ammonium persulfate, 11kg of cork, 6kg of coconut shell, 5kg of male clove , Pulsatilla 5kg, Magnolia officinalis 4kg, Viola 2kg, Huoxiang 2kg, Rhubarb 1kg, deionized water 110kg.

[0025] A kind of preparation technology of above-mentioned high-hardness mildew-resistant wallpaper base film, concrete steps are as follows:

[0026] (1) Weigh the amount of Phellodendron cork, coconut shell, male clove, Psyllium pulsatillae, Magnolia officinalis, Viola chinensis, Huoxiang and rhubarb, add 4 times the weight of deionized water, soak for 2 hours, boil with stro...

Embodiment 2

[0031] A high-hardness mildew-resistant wallpaper base film is made of the following components: 48kg of polyvinyl alcohol (1800 degree of polymerization, 79200 relative molecular mass), 28kg of silicone acrylic emulsion, 20kg of glycidyl methacrylate, 18kg of isocyanate, 20kg of monophenyldiisooctyl phosphite, 8kg of sodium stearate, 8kg of gum arabic, 9kg of gelatin, 8kg of glycerin, 4kg of sodium hexametaphosphate, 3kg of ammonium persulfate, 18kg of cork, 10kg of coconut shell, 8kg of clove , Pulsatilla 8kg, Magnolia officinalis 6kg, Viola 3kg, Huoxiang 3kg, Rhubarb 2kg, deionized water 150kg.

[0032] A kind of preparation technology of above-mentioned high-hardness mildew-resistant wallpaper base film, concrete steps are as follows:

[0033] (1) Weigh the amount of Phellodendron cork, coconut shell, male clove, Psyllium pulsatillae, Magnolia officinalis, Viola chinensis, Huoxiang and rhubarb, add 6 times the weight of deionized water, soak for 3 hours, boil with strong f...

Embodiment 3

[0038] A high-hardness mildew-resistant wallpaper base film is made of the following components: 37kg of polyvinyl alcohol (1700 degree of polymerization, 74800 relative molecular mass), 22kg of silicone acrylic emulsion, 16kg of glycidyl methacrylate, 17kg of isocyanate, 16kg of monophenyldiisooctyl phosphite, 6kg of sodium stearate, 6kg of gum arabic, 7kg of gelatin, 6kg of glycerin, 3kg of sodium hexametaphosphate, 2kg of ammonium persulfate, 12kg of cork, 7kg of coconut shell, 6kg of male clove , Pulsatilla 6kg, Magnolia officinalis 5kg, Viola 2kg, Huoxiang 2kg, Rhubarb 1kg, Deionized water 120kg.

[0039] A kind of preparation technology of above-mentioned high-hardness mildew-resistant wallpaper base film, concrete steps are as follows:

[0040] (1) Weigh the amount of Phellodendron cork, coconut shell, male clove, Psyllium pulsatillae, Magnolia officinalis, Viola chinensis, Huoxiang and rhubarb, add 4 times the weight of deionized water, soak for 3 hours, boil with stro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com