Nanometer fireproof antibacterial environment-friendly coating and preparation method thereof

An environmentally friendly coating, nanotechnology, applied in the direction of fireproof coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of toxicity, long-term antibacterial, etc., and achieve good antibacterial and mildew resistance, good antibacterial Anti-mildew performance, good fire performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

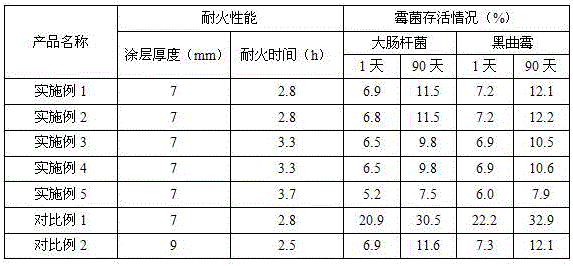

Examples

Embodiment 1

[0017] A kind of nano-fireproof and antibacterial environmental protection coating, prepared from the following ingredients in parts by weight: 10 parts of light calcium carbonate, 5 parts of talcum powder, 3 parts of gypsum powder, 25 parts of titanium dioxide, 2.5 parts of ethylene glycol, 120 parts of demineralized water 2 parts, alcohol ester 12 parts, 20 parts of acrylic emulsion, 1.5 parts of dodecyltrimethylammonium chloride, 0.6 parts of octylphenol polyoxyethylene ether, 1.5 parts of ethanol extract of leaves of cloverleaf, 1.5 parts of ethanol extract of Desmodium 0.5 parts of hydroxypropyl methylcellulose, 5 parts of ammonium polyphosphate, 3 parts of melamine, 2 parts of pentaerythritol, 3 parts of ODOPB, and 10 parts of nano-graphene oxide.

[0018] The preparation method of the above-mentioned nano-fireproof and antibacterial environmental protection coating is as follows: (1) disperse light calcium carbonate, talc powder, gypsum powder, titanium dioxide, ethylene...

Embodiment 2

[0020] A nano-fireproof and antibacterial environmental protection coating, prepared from the following ingredients in parts by weight: 7 parts of light calcium carbonate, 3 parts of talcum powder, 5 parts of gypsum powder, 15 parts of titanium dioxide, 1.5 parts of ethylene glycol, 80 parts of demineralized water 3 parts, 12 parts of alcohol ester, 30 parts of acrylic emulsion, 0.5 part of dodecyltrimethylammonium chloride, 0.1 part of octylphenol polyoxyethylene ether, 0.5 part of ethanol extract of leaves of cloverleaf, 0.5 part of ethanol extract of Desmodium 1.5 parts of hydroxypropyl methylcellulose, 5 parts of ammonium polyphosphate, 6 parts of melamine, 4 parts of pentaerythritol, 5 parts of ODOPB, and 5 parts of nano-graphene oxide.

[0021] The preparation method of the above-mentioned nano-fireproof and antibacterial environmental protection coating is as follows: (1) disperse light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, ethylene glycol, a...

Embodiment 3

[0023] A nano-fireproof and antibacterial environmental protection coating, prepared from the following ingredients in parts by weight: 9 parts of light calcium carbonate, 5 parts of talcum powder, 4 parts of gypsum powder, 22 parts of titanium dioxide, 1.8 parts of ethylene glycol, and 90 parts of demineralized water , 2.8 parts of alcohol ester twelve, 22 parts of acrylic emulsion, 0.8 parts of dodecyltrimethylammonium chloride, 0.5 parts of octylphenol polyoxyethylene ether, 1.2 parts of ethanol extract of leaves of arborvitae, ethanol extract of Desmodium 0.8 parts, 6 parts of hydroxypropyl methylcellulose, 5 parts of ammonium polyphosphate, 3 parts of melamine, 2 parts of pentaerythritol, 3 parts of ODOPB, and 6 parts of nano graphene oxide.

[0024] The preparation method of the above-mentioned nano-fireproof and antibacterial environmental protection coating is as follows: (1) disperse light calcium carbonate, talc powder, gypsum powder, titanium dioxide, ethylene glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com