Tire with polyurethane elastomer material inside and preparation method thereof

A polyurethane elastomer and polyurethane elastic technology, applied in polyurea/polyurethane coatings, tire parts, coatings, etc., can solve the problems of difficult processing and high processing costs, achieve low hardness, prevent tires from leaking, High deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

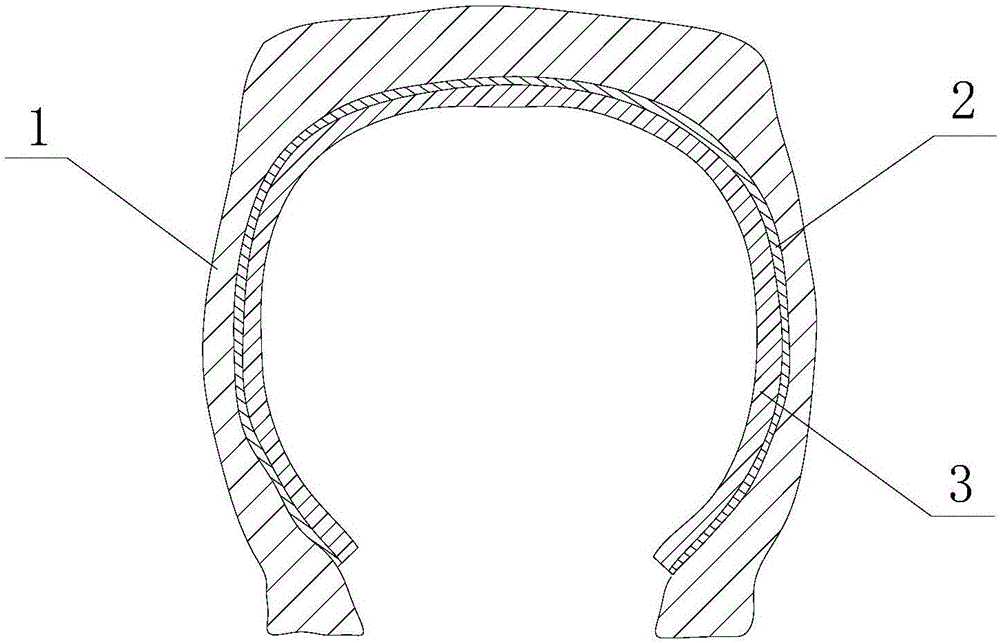

[0042] A tire with a polyurethane elastomer material inside in this embodiment includes a tire body 1, wherein: the tire with a polyurethane elastomer material inside also includes a polyurethane primer layer 2 and a polyurethane elastomer layer 3, so The polyurethane primer layer 2 and the polyurethane elastomer layer 3 are sequentially arranged on the inner surface of the tire body 1 from inside to outside, and the total thickness of the polyurethane primer layer and the polyurethane elastomer layer is 3-4 mm.

[0043] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0044] The A component consists of the following raw materials in weight ratio:

[0045] 20 parts of castor oil, 12 parts of butyl acetate, 38 parts of polymethylene polyphenylisocyanate and 30 parts of trichlorethylene;

[0046] Described B component is made up of the raw material of following weight ratio:

[0047] 40 parts of polytetrahyd...

Embodiment 2

[0063] A tire with a polyurethane elastomer material in this embodiment is the same as that in Embodiment 1.

[0064] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0065] The A component consists of the following raw materials in weight ratio:

[0066] 25 parts of castor oil, 7 parts of butyl acetate, 33 parts of polymethylene polyphenylisocyanate and 35 parts of trichlorethylene;

[0067] Described B component is made up of the raw material of following weight ratio:

[0068] 60 parts of polytetrahydrofuran diol with a relative molecular weight of 1000 and 40 parts of xylene.

[0069] The material for the polyurethane base coat 2 is made by the following steps:

[0070] (1) Synthesis of component A: put 25 parts of castor oil in a reactor with a condenser, dehydrate for 2 hours at 120°C and a vacuum of -0.09Mpa, cool down to 40°C after dehydration, and take acetic acid Add 7 parts of butyl ester into...

Embodiment 3

[0084] A tire with a polyurethane elastomer material in this embodiment is the same as that in Embodiment 1.

[0085] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0086] The A component consists of the following raw materials in weight ratio:

[0087] 21 parts of castor oil, 11 parts of butyl acetate, 37 parts of polymethylene polyphenylisocyanate and 31 parts of trichlorethylene;

[0088] Described B component is made up of the raw material of following weight ratio:

[0089] 45 parts of polytetrahydrofuran diol with a relative molecular mass of 1000 and 55 parts of xylene.

[0090] The material for the polyurethane base coat 2 is made by the following steps:

[0091] (1) Synthesis of component A: put 21 parts of castor oil in a reactor with a condenser, dehydrate for 2 hours at 120°C and a vacuum of -0.09Mpa, cool down to 40°C after dehydration, and take acetic acid Add 11 parts of butyl ester into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com