Method for detecting sulfur content in raw coal

A technology of sulfur content and raw coal, applied in the field of coal chemical industry, can solve the problems of insufficient detection sensitivity, high detection cost, high detection limit, etc., and achieve the effect of weakening spectral interference, improving sensitivity and reducing samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

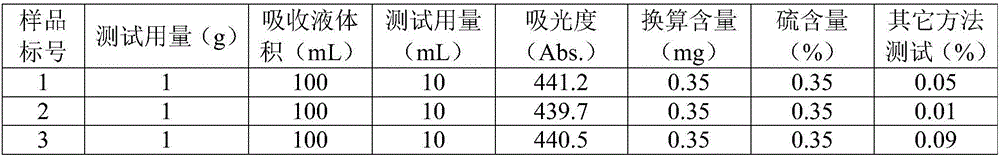

Examples

Embodiment 1

[0021] (1) Prepare pararosaniline (PRA) solution: draw 25mL of PRA stock solution (0.20g / 100mL) into a 100mL volumetric flask, add 30mL of 85% phosphoric acid, 12mL of concentrated hydrochloric acid, dilute with water to the mark, and shake well.

[0022] (2) Formaldehyde absorption solution: absorb 5.5mL of 36%-38% formaldehyde solution, 20.00mL of CDTA-2Na solution, weigh 2.04mg of potassium hydrogen phthalate, dissolve in a small amount of water, combine the three solutions, and then Dilute to 100mL with water.

[0023] (3) Configure sulfur dioxide standard solution: take 0.2g of sodium sulfite and dissolve it in 200mL of water, take 20mL of the above solution and dilute it to 100 / 250 / 500 / 1000mL, etc.; curve.

[0024] (4) Combust 100mg of raw coal in a small boiler, and absorb the exhaust gas through the pipeline with excess formaldehyde absorbing liquid to enrich sulfur dioxide in the formaldehyde solution.

[0025] (5) Pipette 50 mL of the enriched formaldehyde solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com