Inverted bulk heterojunction organic solar cell

A solar cell and bulk heterojunction technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unfavorable carrier transport and collection, active layer thickness, and low absorption efficiency of solar light by active layer materials. Achieve broad market application prospects, low cost, and improve the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The materials used in the present invention are: zinc oxide (ZnO), [poly[4,8-bis[(2-ethylhexyl)oxy]benzo[1,2-b:4,5-b']dithiophene-2,6 -diyl][3-fluoro-2-[(2-ethylhexyl)-carbonyl]-thieno-[3,4-b]thiophenediyl](PTB7),[6,6]-phenyl-C 70 -butyric-acid-methyl-ester] (PC 70 BM), molybdenum trioxide (MoO 3 ), silver, Liby detergent (composed of demineralized water, surfactant, vitamin E ester, lemon essence), sodium dodecyl sulfate (SDS), deionized water, acetone, isopropanol, PDMS. Its combined dosage is as follows:

[0021] Zinc oxide solution: 70 µl

[0022] PTB7: 10 mg ± 1 mg

[0023] PC 70 BM: 15mg±1mg

[0024] MoO 3 : 1g±0.01g

[0025] Silver: Ag 10 g±0.01 g

[0026] Dish soap: 2±0.5ml

[0027] Sodium dodecyl sulfate (SDS): 1±0.5 g

[0028] Deionized water: H 2 O 8000ml±50ml

[0029] Acetone: CH 3 COCH 3 250ml±5ml

[0030] Conductive glass: indium tin oxide ITO 25 mm×25 mm×1 mm

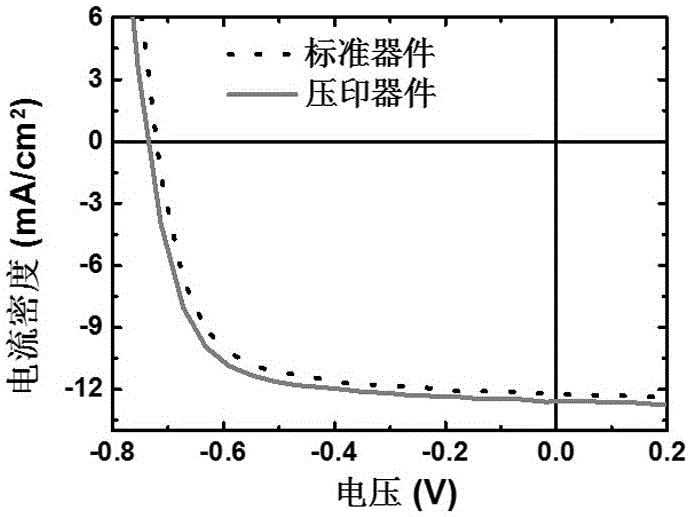

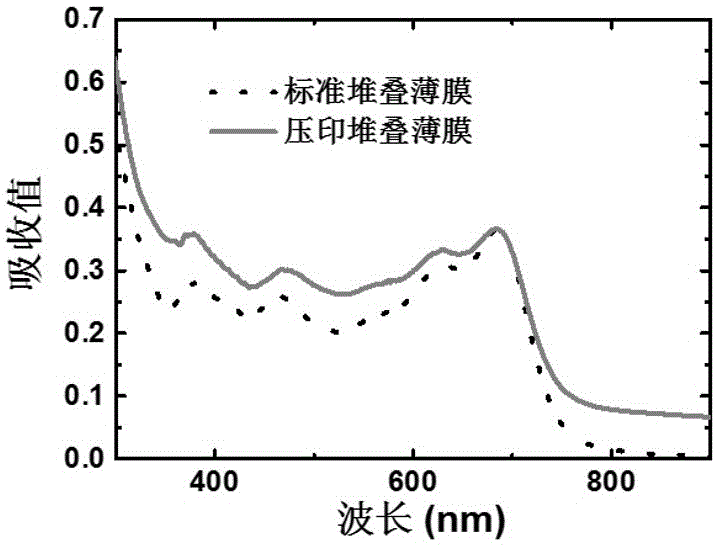

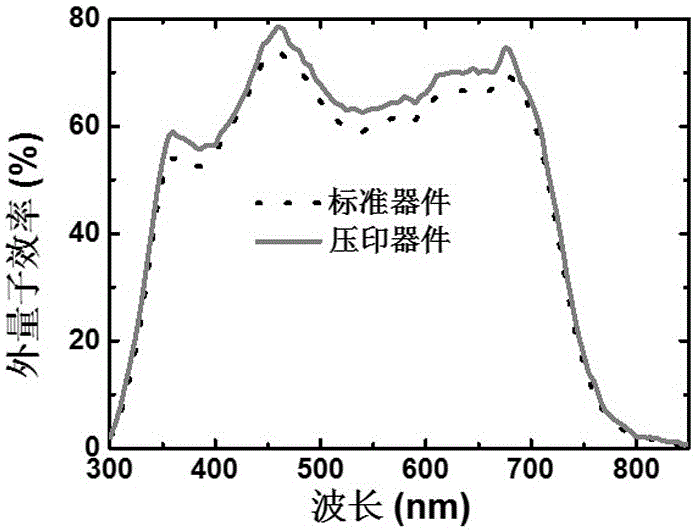

[0031] The organic solar cell device of the present invention has a five-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com