Method for reducing acrylamide generation in high-temperature processed food with fermented acidic juice

A technology of high temperature processing and acid juice, applied in bakery food, food science, dough processing and other directions, can solve the problem of unfavorable inhibition of acrylamide and high sugar content, and achieve the effect of inhibiting the formation of acrylamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Lactobacillus casei is used as fermented probiotic strain and lemon and apple mixed juice is used as fermented liquid, and the concentrated fermented lemon and apple juice fermented by Lactobacillus casei is added to biscuit making under high temperature conditions.

[0023] The specific operation process is as follows:

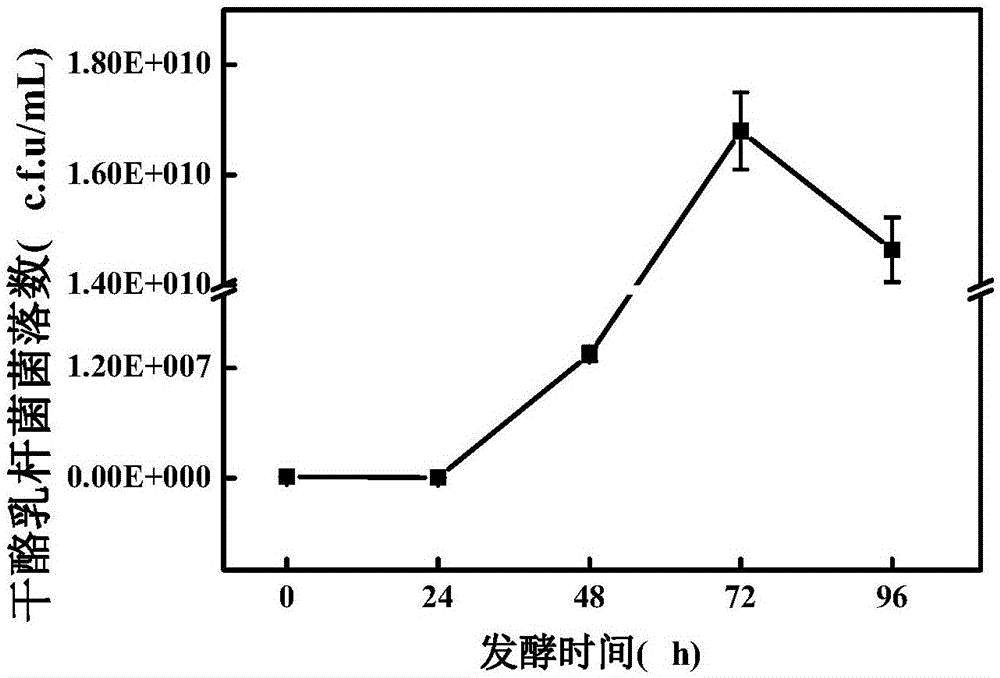

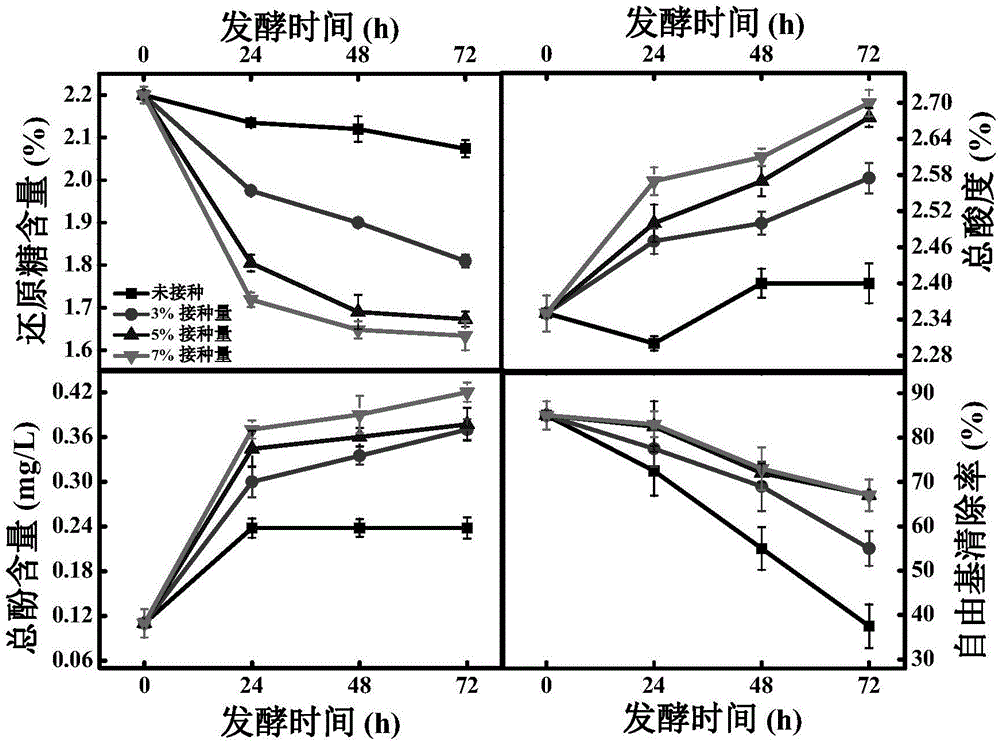

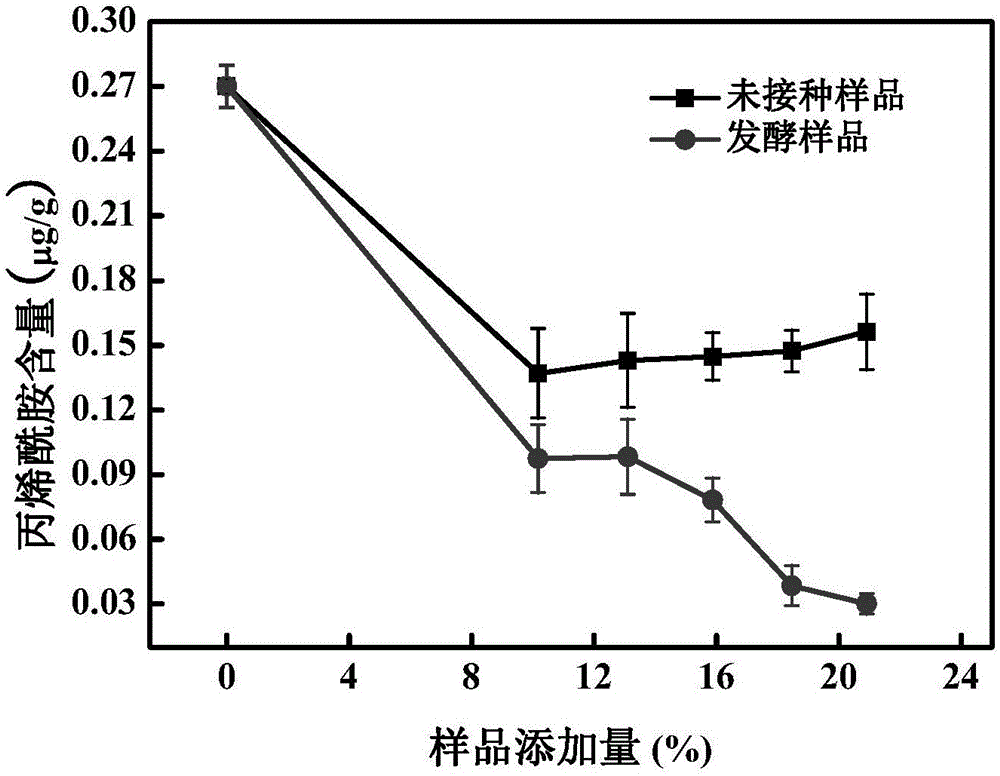

[0024] 1. Making fermented acidic juice: remove the core and peel of fresh lemons and apples, squeeze the juice with a juicer, filter with gauze, centrifuge at 8000r / min for 15min, and take the supernatant to obtain lemon juice and apple juice respectively. Adjust the lemon juice with apple juice to pH = 3, as a fermented liquid, after pasteurization (90°C, 15min), insert Lactobacillus casei 1-7% (v / v) into the constant temperature culture at 30-40°C Static fermentation in the box for 1-7 days (combined with see figure 1 ), filtered to obtain fermented acidic juices with different concentrations and different fermentation times.

[0025] 2. Detection...

Embodiment 2

[0030] Taking Lactobacillus acidophilus as the fermented probiotic strain, taking peach juice as the fermented liquid (centrifugal 4000r / min, 30min), the inoculation volume is 4%, and the method in Example 1 makes fermented acidic fruit juice (sterilizing 85 ℃ , 20min). The obtained fermented acidic fruit juice is added to the processing and production of bread according to the addition amount of 5% of the raw material weight, and the processed finished product is tested, and the result shows that the inhibition rate of acrylamide is 68%.

Embodiment 3

[0032] Take kefir bacteria as the fermented probiotic strains, and use apples, oranges and pears as raw materials to prepare a fermented liquid of pH=3 (centrifugation 10000r / min, 10min), the inoculation volume is 5%, according to the method in Example 1 Methods Fermented acidic juice was prepared (sterilized at 90°C for 15 min). The obtained fermented acidic fruit juice is added to the processing and production of potato chips according to the addition amount of 15% of the raw material weight, and the processed finished product is tested, and the result shows that the inhibition rate to acrylamide is 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com